- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

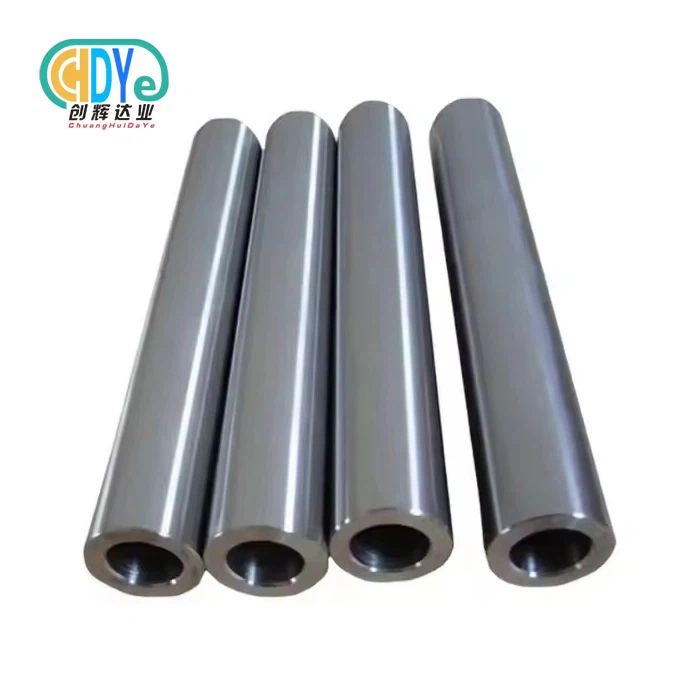

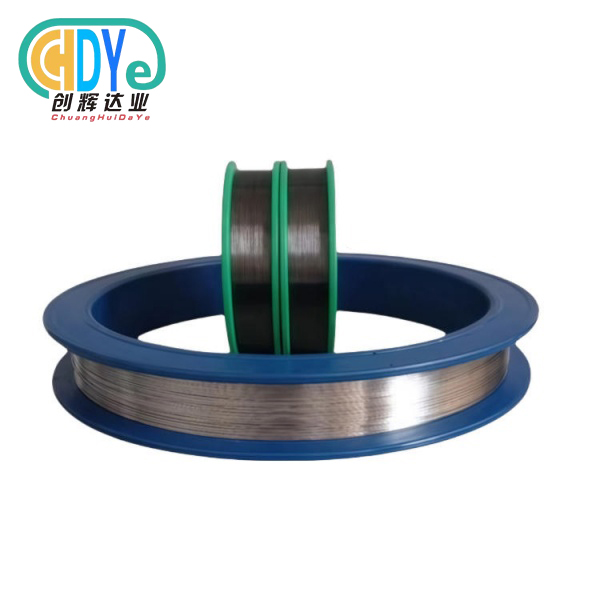

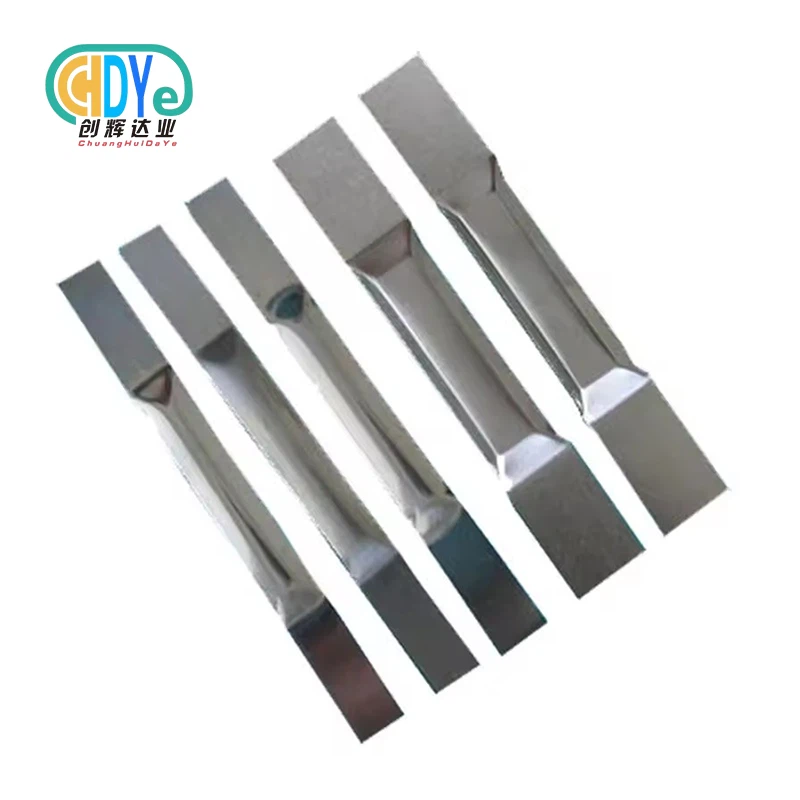

Tantalum Alloy Sheet and Plates

Product Introduction

The Tantalum Alloy Sheet and Plates are high-purity refractory metal materials known for their outstanding resistance to corrosion, high-temperature strength, and excellent ductility. Produced with advanced electron beam melting and precise rolling technology, these products maintain uniform thickness, smooth surfaces, and stable mechanical properties. They are widely used in chemical processing, aerospace, semiconductor, and medical industries, where durability and purity are critical. Shaanxi Chuanghui Daye Metal Material Co., Ltd. supplies Tantalum Alloy Sheet and Plates in accordance with ASTM B708 and other international standards, ensuring reliable performance in the most demanding environments.

Chdymetal provides a wide range of tantalum and tantalum alloy products, including ultra-thin and ultra-wide plates, to meet the unique requirements of different industries. Tantalum alloy sheet and plates, produced through a rolling process, offer exceptional performance and a uniform grain structure.

Specification:

Grade: R05200, R05400, R05252, R05255

Size: Thickness 0.5-20mm*width50-1200*Length30-2500mm

Standard: ASTM B708

Type: foil strip shape are all available

Delivery: stock size will arrange within 1-3 days, normal production time about 15 working day.

Order Processing

1.First contact us to provide the grade, size ,quantity and standard or any special requirements

2.We will reply you the quotation with delivery time in 3 hours.

3.Reach an agreement the buyer arrange the prepayment

4.When we get your payment we will arrange production asap and share you the production progress.

5.When production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment

6.Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate

8.Regular after-sales service to know the actual product usage

Application Advantages

*It is used for laboratory equipment

*It is used for manufacturing heating elements, insulating parts, and loading vessels for vacuum furnaces.

*It is used for manufacturing superalloys and electron-beam melting, superalloy additive

*It is sed in metallurgical, machinery processing, glass, and ceramic industries

*It is Used for sputtering targets

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye Metal Material Co., Ltd. follows a refined and controlled production process for Tantalum Alloy Sheet and Plates, ensuring top-tier quality and consistency:

- Raw Material Selection – Only certified high-purity tantalum ingots are used.

- Electron Beam Melting – Advanced purification ensures uniform alloy composition.

- Hot Forging & Rolling – Enhances strength and grain uniformity.

- Annealing Treatment – Improves ductility and relieves internal stress.

- Precision Machining & Surface Finishing – Achieves tight tolerance and mirror-like surfaces.

- Final Inspection & Packing – Each sheet and plate undergoes strict dimensional and purity checks before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Our company maintains full compliance with ISO 9001:2015 standards to ensure each batch of Tantalum Alloy Sheet and Plates meets customer expectations. Quality control measures include:

- Chemical composition testing (ICP, XRF analysis)

- Mechanical property testing (tensile strength, elongation, hardness)

- Ultrasonic and eddy current non-destructive testing

- Visual and dimensional inspections for surface quality

- Final certification and traceable batch documentation

R&D and Customization

With a professional R&D team and decades of technical experience, we provide:

- Custom grades and alloy ratios for specialized use

- Tailor-made thickness, width, and surface conditions

- Prototype development for vacuum, semiconductor, and aerospace applications

- Continuous innovation to improve corrosion resistance and mechanical performance

Packaging & Global Logistics

Each Tantalum Alloy Sheet and Plates product is securely packaged to ensure safety during global transportation:

- Packaging: Vacuum-sealed or anti-rust film, foam protection, and export-grade wooden cases.

- Labeling: Clear identification with size, grade, and batch number.

- Transportation: Reliable global logistics by air, sea, or express with fast dispatch capability.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides complete OEM/ODM support for global buyers, including:

-

Custom cutting, rolling, and polishing

-

Specialized alloy composition on request

-

Technical consultation and engineering assistance

-

Small-batch or bulk order production with flexible delivery schedules

Inspection Process

Every Tantalum Alloy Sheet and Plates undergoes a rigorous inspection sequence:

-

Incoming raw material verification

-

Melting composition analysis

-

Rolling and dimensional measurement

-

Non-destructive testing

-

Surface and finish evaluation

-

Final product certification and packaging inspection

Why Choose Us

-

Over 30 years of expertise in rare and refractory metals

-

Exporting to 50+ countries with excellent international reputation

-

Full ISO 9001:2015 certified production system

-

Custom design, size, and alloy solution capability

-

Professional after-sales service and technical support

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your tantalum alloy materials?

A1: Our Tantalum Alloy Sheet and Plates typically offer 99.9% purity or higher, depending on customer requirements.

Q2: Can you provide custom sizes or surface finishes?

A2: Yes, we can produce custom thicknesses, polished or matte surfaces, and special alloy compositions.

Q3: What are the main applications of tantalum alloys?

A3: Common uses include chemical process reactors, heat exchangers, capacitor components, and medical devices.

Q4: How long is the delivery time?

A4: Standard sizes are available for quick delivery within 7–10 days; customized orders may vary.

Q5: Do you provide testing reports?

A5: Yes, we provide full mill test certificates, composition analysis reports, and mechanical property test results.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email