- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

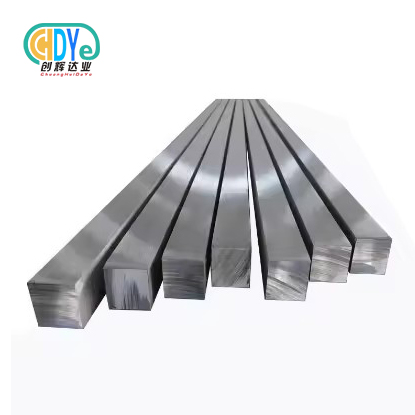

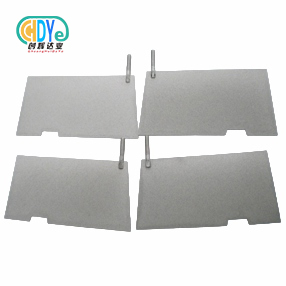

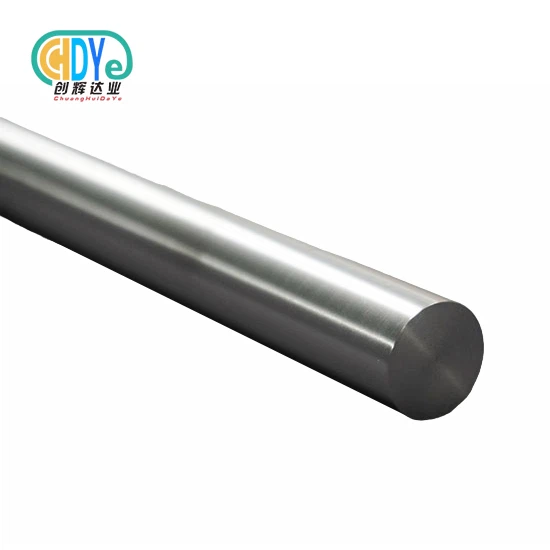

customized tantalum target

2.Density:16.6 g/ cm 3

3.Purity : 99.95%min

4.size: customized

5.Condition: Vacuum Annealed

6.Surface: Alkaline wash surface / machined

Are you looking for high-quality tantalum targets that meet your exact specifications? Our customized tantalum target solutions deliver exceptional performance for semiconductor, optical, and aerospace applications. With over 30 years of experience in rare metal manufacturing, we provide precision-engineered targets with purity levels from 99.8% to 99.99%. Each target is manufactured to your unique requirements, ensuring optimal performance in your specific applications.

Product Introduction

Our tantalum targets combine superior material properties with precision manufacturing. Tantalum is a rare, hard, bluish-gray refractory metal with exceptional corrosion resistance. With a melting point of 2980°C and density of 16.68 g/cm³, tantalum offers outstanding performance characteristics. These include high melting point, low vapor pressure, excellent cold working properties, and strong chemical stability.

Key Features and Benefits

- Ultra-high Purity: 99.8–99.99% purity levels suitable for critical applications

- Precision Machining: CNC processing achieves ±0.005 mm accuracy

- Custom Designs: Planar, tubular, or stepped configurations available

- Superior Surface Finish: Ra ≤0.4 μm for optical precision requirements

- Stress Relief Treatment: Heat treatment at 600–900°C eliminates internal stress

- High Density: ≥99.9% theoretical density using Hot Isostatic Pressing (HIP)

Technical Specifications

| Parameter | Specification |

|---|---|

| Grade | Ta 1, Ta 2 |

| Purity | 99.95% minimum |

| Density | 16.6 g/cm³ |

| Melting Point | 2980°C |

| Surface Finish | Alkaline wash / Machined |

| Processing Method | CNC Milling Machinery |

| Condition | Vacuum Annealed |

Chemical composition

|

Grade |

Main component |

Impurity content(≤) |

||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Balance |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta2 |

Balance |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

Available Grades and Materials

We offer various tantalum grades to meet your specific requirements:

- Standard Tantalum: Ta 1 and Ta 2 grades with 99.95% minimum purity

- High-Purity Options: Up to 99.99% purity for critical applications

Manufacturing Process

Our advanced manufacturing process ensures consistent quality. We start with tantalum powder from sodium thermal reduction. The powder undergoes cold isostatic pressing at >200 MPa pressure. Sintering occurs in vacuum conditions >10⁻² MPa at temperatures >2400°C.

The sintered ingot is rolled with 30%-60% processing rate. Heat treatment follows at 25%-45% of tantalum's melting point. This powder metallurgy approach creates fine, uniform internal structure. The result is texture-free material perfect for high-end sputtering applications.

|

|

|

|

|

|

|

|

Applications and Industries

Electronic Chip Manufacturing: Essential for semiconductor integrated circuit production. Creates tantalum thin films for capacitors and resistors. Precise sputtering control enables accurate thin film deposition.

Display Technology: Used in LCD and OLED manufacturing. Forms electrode and barrier layer structures. Improves electrical performance, stability, and lifespan.

Optical Coating: Enhances optical products like lenses and coated glass. Improves transmittance while reducing reflection. Provides wear resistance for camera lenses and architectural glass.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

All dimensions are fully customizable to your specifications:

- Size Range: From small research targets to large industrial applications

- Thickness Tolerance: ±0.005 mm with CNC machining

- Surface Roughness: Ra ≤0.4 μm achievable

- Geometric Options: Round, rectangular, or complex shapes available

Quality Assurance and Testing

Every customized tantalum target undergoes rigorous quality testing. We verify chemical composition, density measurements, and dimensional accuracy. Surface quality inspection ensures meeting your specifications. All products include comprehensive test certificates.

|

|

|

OEM & Customization Services

We specialize in creating targets that match your exact needs. Our engineering team works with you to optimize design parameters. Whether you need specific dimensions, purity levels, or surface treatments, we deliver solutions that exceed expectations.

Packaging and Shipping

Products are carefully packaged to prevent damage during transport. We use protective materials suitable for metal products. Shipping arrangements accommodate both domestic and international delivery. Our products successfully serve customers in over 50 countries worldwide.

Why Choose Us

Located in Baoji, China's "Titanium Capital," we offer unmatched expertise. Our founder brings over 30 years of rare metal industry experience. We focus on competitive pricing, on-time delivery, and customer-focused service. Trust, reliability, and continuous improvement define our approach to every customized tantalum target project.

|

|

|

|

|

|

FAQs

Q: What purity levels are available?

A: We offer purity levels from 99.8% to 99.99%, depending on your application requirements.

Q: What's the typical lead time?

A: Lead times vary based on specifications and quantity. Contact us for specific timeline estimates.

Q: Can you provide small quantities for research?

A: Yes, we accommodate both research quantities and large-scale production orders.

Contact Us

Ready to discuss your tantalum target requirements? Our experienced team is here to help you find the perfect solution. Contact us today at info@chdymetal.com to start your project. Let us show you why customers worldwide trust us for their precision metal needs.

Learn about our latest products and discounts through SMS or email