- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

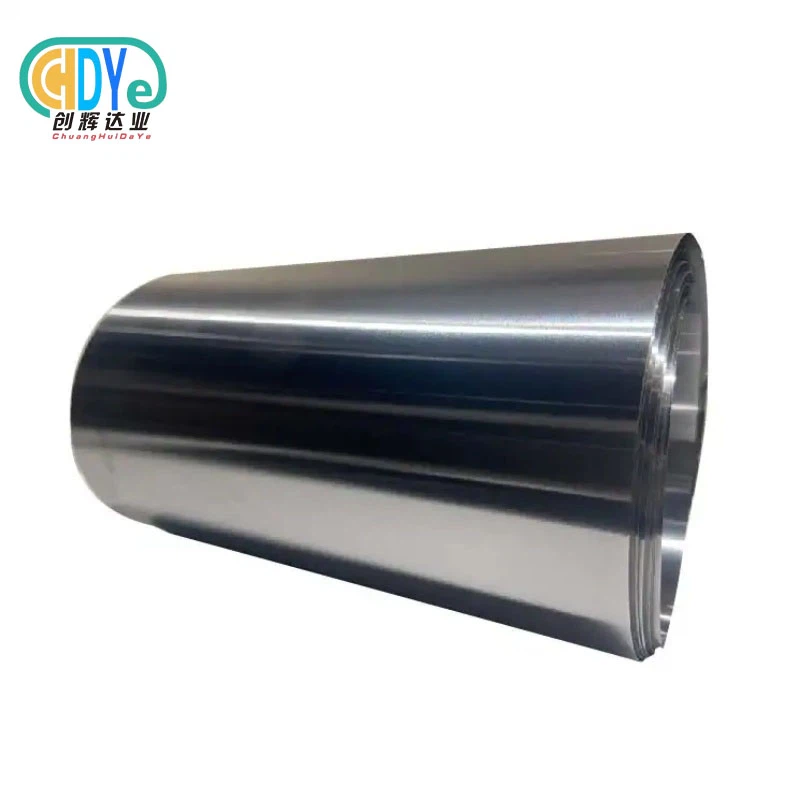

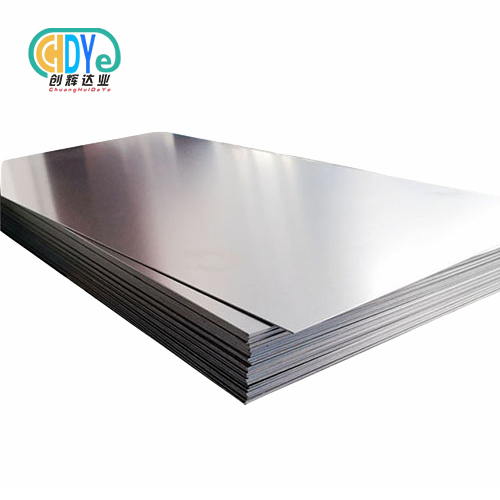

Gr2 Titanium Foil

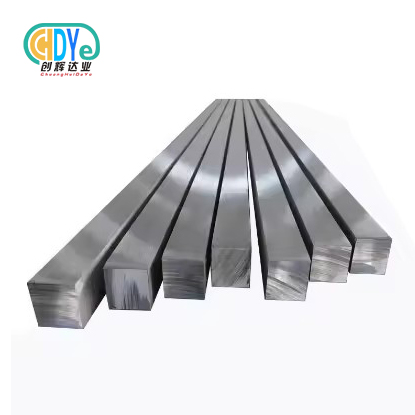

o ther Grade support customized

2.Size:T (0.1mm - 10.0mm) * W (10-1000mm) * L as your request

Product Overview

Gr2 Titanium Foil is a premium-grade, commercially pure titanium material known for its exceptional corrosion resistance, light weight, and outstanding formability. It is widely used in electronics, aerospace, chemical, and precision manufacturing industries where high purity and stability are essential. With a fine grain structure and smooth surface, it is ideal for applications requiring ultra-thin, flexible, and corrosion-proof titanium material.

Titanium alloy has high strength and low density, good mechanical properties, good toughness and corrosion resistance.

|

Standard |

ASTM B265,ASTMF67, ASTM F136 |

|

Grade |

Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr12 Gr23 |

|

Size |

T (0.1mm - 10.0mm) * W (10-1000mm) * L as your request |

|

Technique |

Hot rolled, cold rolled |

|

surface |

Bright, Polished, Pickling, Acid cleaning, Sandblasting |

|

Application |

Pressure vessel |

|

Application |

Chemical, industry, sports etc. |

|

Feature |

High corrosion resistance, low density, good thermal stability |

|

Packaging |

1. cases packed in wooden cases |

|

Composition (%) |

C |

N |

Fe |

O |

H |

Al |

v |

Ti |

|

GR1 |

≤0.08 |

≤0.03 |

≤0.20 |

≤0.18 |

≤0.015 |

-- |

Bal |

|

|

GR2 |

≤0.08 |

≤0.03 |

≤0.30 |

≤0.25 |

≤0.015 |

--- |

Bal |

|

|

GR5 |

≤0.10 |

≤0.05 |

≤0.30 |

≤0.20 |

≤0.015 |

5.50-6.80 |

3.50-4.50 |

Bal |

|

Grade |

Tensile Strength |

Yield Strength 0.2% Offset |

Elongation |

Bend Test |

|

|

Min |

Min |

Min Max |

|

Under 0.070 in.(1.8mm)in thickness |

|

|

KSI |

MPA |

Ksi MPA KSI MPA |

|||

|

1 |

35 |

240 |

20 138 45 310 |

24 |

1.5T |

|

2 |

50 |

345 |

40 275 65 450 |

20 |

2T |

|

3 |

65 |

450 |

55 380 80 550 |

18 |

2.5T |

|

4 |

80 |

550 |

70 483 95 655 |

15 |

3T |

Product Characteristics and Advantages

- Excellent Corrosion Resistance: Performs well in seawater, acid, and alkali conditions.

- Lightweight and Flexible: Easy to form, bend, and shape for thin-wall applications.

- Stable Chemical Composition: High titanium purity ensures long-term reliability.

- Good Thermal Conductivity: Suitable for electronic and heat-dissipation parts.

- Uniform Thickness Control: Precision rolling technology ensures consistency.

- Clean and Bright Surface: Optimized for further coating, welding, or laminating.

Manufacturing & Processing Capability

Our production process for Gr2 Titanium Foil involves precision cold rolling, annealing, and vacuum leveling to achieve superior thickness uniformity and mechanical performance. Equipped with advanced rolling mills, vacuum furnaces, and high-precision inspection systems, we can ensure:

- High surface flatness and clean finish

- Stable chemical composition verified by spectrometry

- Tight thickness tolerance within ±0.005 mm

- Consistent coil-to-coil quality control

- Custom cut-to-length and slit width for mass production

|

|

|

|

|

|

|

|

Quality Assurance

Every batch of Gr2 Titanium Foil is inspected and certified according to international standards. Our quality management system ensures complete process traceability and consistency.

- Certified to ISO 9001:2015 and ISO 13485 (for medical use)

- Non-destructive testing (NDT) and ultrasonic inspection

- Chemical composition verified by spectrographic analysis

- Mechanical testing for strength, elongation, and hardness

- Surface inspection for visual defects, burrs, and roughness

Application Advantages

-

1. Aerospace industry: Titanium foil has a wide range of applications in the aerospace field. It is used to manufacture aircraft structural components, engine parts, and missile casings. Due to its lightweight, high strength, and corrosion resistance, titanium foil can reduce aircraft weight, improve fuel efficiency, and extend service life.

- 2. Chemical industry: Titanium foil is used in the chemical industry to manufacture equipment such as storage tanks, heat exchangers, and reactors. Due to its corrosion resistance and high temperature stability, titanium foil can withstand harsh chemical environments and high temperature conditions, providing reliable protection for chemical processes.

- 3. Medical industry: Titanium foil has important applications in the medical field. It is used to manufacture medical devices such as artificial joints, dental implants, and surgical instruments. Due to its biocompatibility and antibacterial properties, titanium foil can reduce implant rejection and infection risks, and improve surgical success rates.

- 4. Automotive industry: Titanium foil is also widely used in the automotive industry. It is used to manufacture key components such as exhaust systems, chassis, and body structures for automotive engines. The lightweight, high strength, and corrosion resistance of titanium foil can improve the performance and energy-saving effect of automobiles.

- 5. Electronics industry: Titanium foil is used to manufacture capacitors, batteries, and electronic components. Due to its excellent conductivity and high-temperature stability, titanium foil can provide good electrical performance and reliability.

- Titanium foil is a metal material with excellent performance and wide application fields. With the continuous innovation and development of technology, the application fields of titanium foil will continue to expand, bringing more innovation and progress to various industries.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Packaging & Logistics

Each foil roll is wrapped in anti-static film, vacuum-sealed, and protected with foam inserts before being placed in export-grade wooden boxes. Labels include material grade, batch number, and dimensions. Global logistics partners ensure fast and safe delivery for wholesale customers.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Services

- Custom thickness (0.01–0.5 mm) and width options

- Surface treatment: bright, pickled, or matte finish

- Roll or sheet supply formats for industrial applications

- Slitting, stamping, and laminating available on request

- Long-term OEM partnerships for global distributors

Global Market & Cooperation

Our Gr2 Titanium Foil is exported to over 40 countries including the USA, Japan, Germany, South Korea, and India. We support long-term supply agreements with electronics, aerospace, and chemical equipment manufacturers, ensuring steady quality and reliable logistics for large-scale procurement.

Feedback from customers

Why Choose Us :

1. You can get the perfect material according to your requirement at the least possible price.

2. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

5. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Sample order is supported!

|

|

|

|

|

|

Gr2 Titanium Foil Transaction Process

1.First contact us to provide the grade, size ,quantity and standard or any special requirements.

2.we will reply you the quotation with delivery time in 3 hours.

3.reach an agreement then buyer arrange the prepayment.

4. when we get your payment we will arrange production asap and share you the production progress.

5.when production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment.

6. Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate.

8. Regular after-sales service to know the actual product usage.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Chdymetal have more than 30year's experience in Non-ferrous metal industry, Gr2 Titanium Foil is one of our main products, we have common size in stock all year round and we can arrange 1-3days quick delivery.

Welcome to contact us for more information: info@chdymetal.com/ Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email