- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

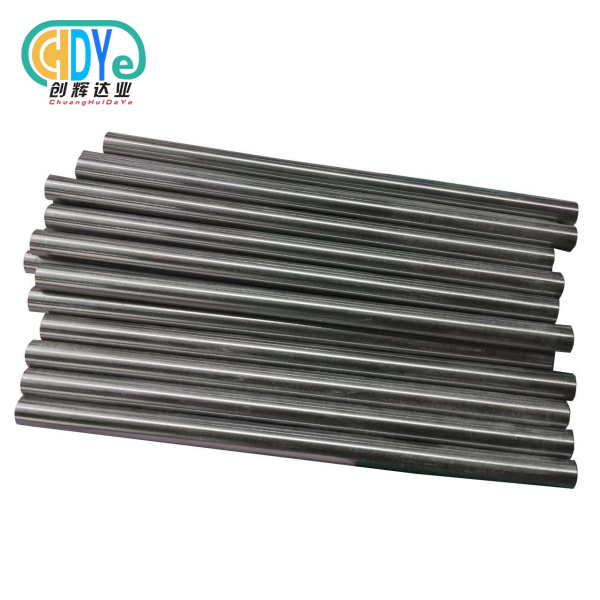

seamless tantalum tube

2. Outer diameter: 5–200 mm

3. Wall thickness: 0.5–20 mm

4. Length: up to 3000 mm

5. Density: 16.65 g/cm³

6. Applications: Chemical, medical

7. Corrosion resistant

Product Introduction

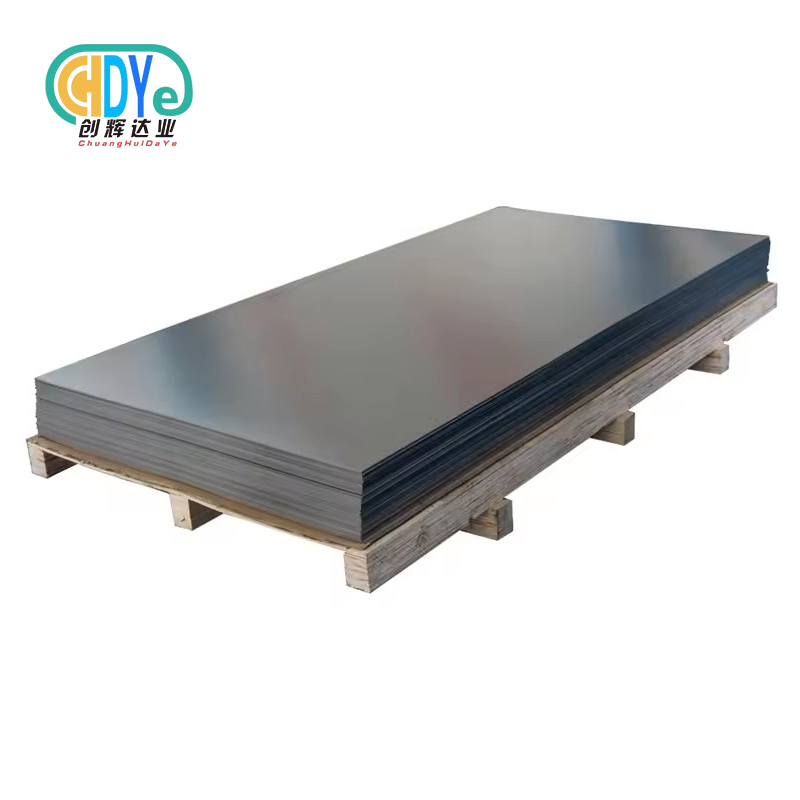

When you need reliable, high-performance tubing for demanding applications, our seamless tantalum tube delivers exceptional quality and durability. These tubes are manufactured through an advanced extrusion process, creating a hollow form without welded seams from solid tantalum billets. Our tantalum tubes offer superior corrosion resistance and mechanical strength, making them ideal for chemical processing, medical equipment, and specialized industrial applications where reliability matters most.

Key Features and Benefits

Our tantalum tubes provide numerous advantages for your critical applications:

- Superior Corrosion Resistance: Naturally resistant to most chemicals and acids

- High Temperature Stability: Maintains integrity at extreme temperatures up to 5,463°F (2,996°C)

- Seamless Construction: No welded joints means better structural integrity

- Biocompatibility: Safe for medical and pharmaceutical applications

- Long Service Life: Minimal maintenance requirements reduce operational costs

- Excellent Ductility: Easy to bend, shape, and machine for custom applications

Technical Specifications

Chemcial composition

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Mechanical Properties (Annealed)

|

Grade |

Tensile Strength min, lb/in2 (MPa) |

Yield Strength min, lb/in2 (MPa) |

Elongation, min%, 1 inch gauge length |

|

R05200/R05400 |

30000(207) |

20000(138) |

25 |

|

R05252 |

40000(276) |

28000(193) |

20 |

|

R05255 |

70000(481) |

60000(414) |

15 |

|

R05240 |

40000(276) |

28000(193) |

20 |

Available Grades and Materials

We offer various tantalum grades to meet your specific requirements:

- R05200: Unalloyed tantalum, electron-beam furnace melt

- R05400: Unalloyed tantalum, powder-metallurgy consolidation

- R05252: Tantalum-tungsten alloy (97.5% Ta, 2.5% W)

- R05255: Tantalum-tungsten alloy (90% Ta, 10% W)

Each grade provides unique properties suited for different operating conditions and performance requirements.

Manufacturing Process

Our seamless tantalum tube production follows strict quality protocols:

- Material Selection: High-purity tantalum billets are carefully inspected

- Extrusion Process: Tubes are drawn from solid billets using advanced machinery

- Heat Treatment: Controlled annealing ensures optimal mechanical properties

- Precision Machining: Tubes are machined to exact dimensional specifications

- Quality Testing: Each tube undergoes comprehensive inspection before shipment

|

|

|

|

|

|

|

|

Applications and Industries

Tantalum tubes serve critical roles across multiple industries:

- Chemical Processing: Reactor vessels, heat exchangers, and piping systems

- Medical Equipment: Surgical instruments and implantable devices

- Electronics: Capacitor manufacturing and semiconductor equipment

- Aerospace: High-temperature components and specialized systems

- Research Facilities: Laboratory equipment and analytical instruments

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight tolerances to ensure your applications perform flawlessly:

- Outer Diameter Tolerance: ±0.05mm for diameters under 50mm

- Wall Thickness Tolerance: ±0.02mm for walls under 2mm

- Length Tolerance: ±1mm for standard lengths

- Straightness: Maximum deviation 0.5mm per meter

- Surface Roughness: Ra ≤ 0.8μm

Quality Assurance and Testing

Every seamless tantalum tube undergoes rigorous testing:

- Chemical Composition Analysis: Verified purity levels

- Dimensional Inspection: Precise measurement verification

- Surface Quality Check: Visual and tactile examination

- Mechanical Testing: Tensile strength and hardness evaluation

- Corrosion Resistance Testing: Chemical exposure verification

|

|

|

OEM & Customization Services

We understand that your applications may require specific configurations. Our experienced team can customize:

- Special dimensions and tolerances

- Unique alloy compositions

- Custom surface treatments

- Specialized packaging requirements

- Modified delivery schedules

Packaging and Shipping

Your tubes are carefully packaged to prevent damage during transit:

- Individual protective wrapping for each tube

- Cushioned shipping containers

- Detailed quality certificates included

- International shipping available

- Expedited delivery options when needed

|

|

|

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of rare metal expertise to every project. Located in China's "Titanium Capital," we combine traditional craftsmanship with modern manufacturing techniques. Our products serve customers in more than 50 countries, demonstrating our commitment to quality and reliability.

1. Rich experience in metal industry and we can give you professional advice when you choose in your application

2. Stock products with various grade and size, we can arrange quick delivery.

3. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

|

|

|

|

|

|

FAQs

Q: What makes seamless tubes better than welded tubes?

A: Seamless construction eliminates potential weak points from welding, providing superior structural integrity and pressure resistance.

Q: Can tantalum tubes be polished if scratched?

A: Yes, you can restore the surface using nylon pads or cream metal polish with a soft cloth, followed by thorough rinsing.

Q: What maintenance do tantalum tubes require?

A: Minimal maintenance is needed. Simple cleaning with mild soap and water followed by soft cloth drying is typically sufficient.

Q: Are custom dimensions available?

A: Absolutely. We offer comprehensive customization services to meet your specific dimensional and performance requirements.

Contact Us

Ready to discuss your seamless tantalum tube requirements? Our technical team is here to help you select the perfect solution for your application.

Email: info@chdymetal.com

Contact us today for detailed quotations, technical specifications, or custom manufacturing consultations. We're committed to providing you with the highest quality tantalum products and exceptional customer service.

Learn about our latest products and discounts through SMS or email

_1760923994993.jpg)