- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

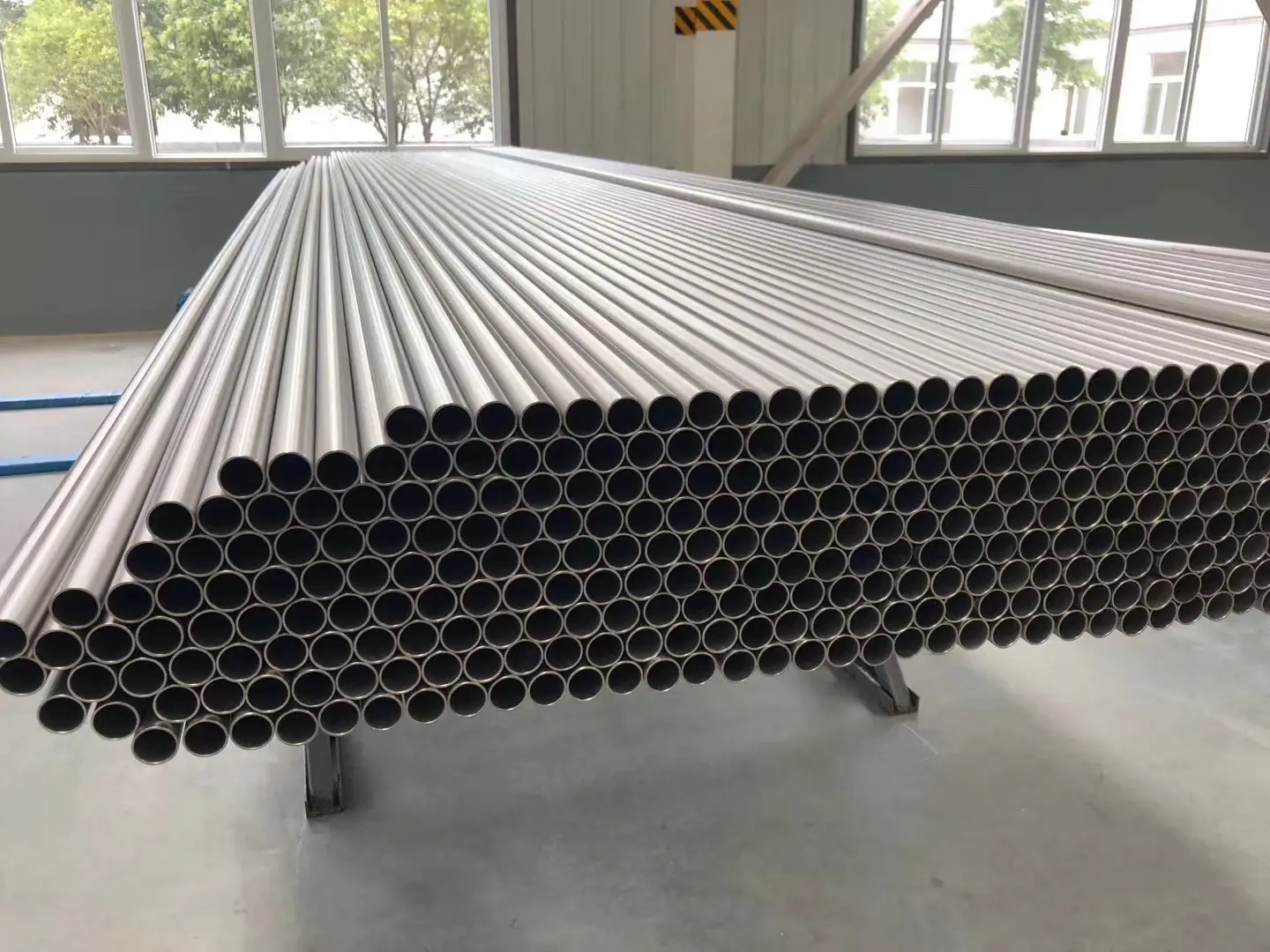

Titanium Welded Pipe

Product Introduction

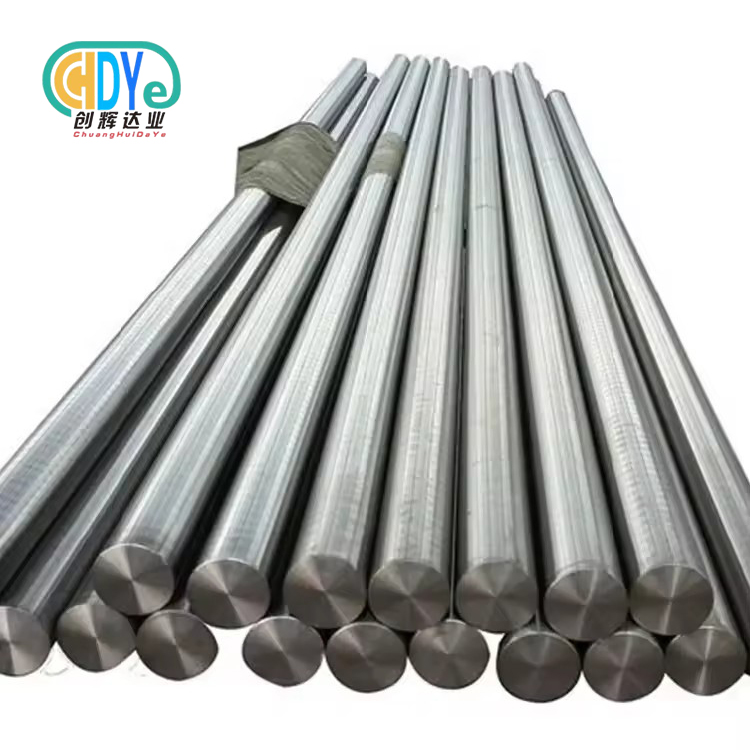

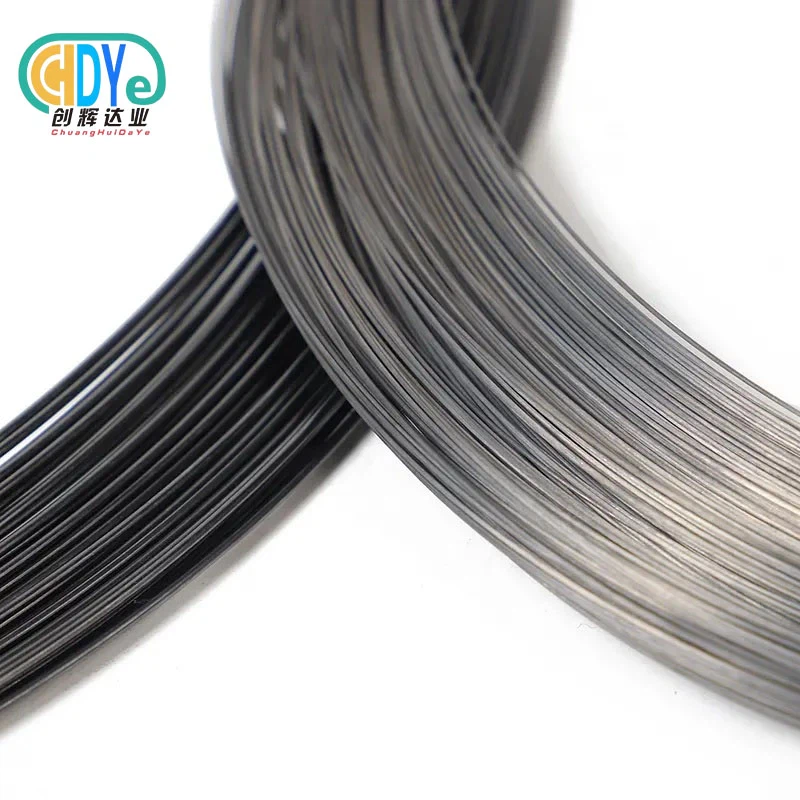

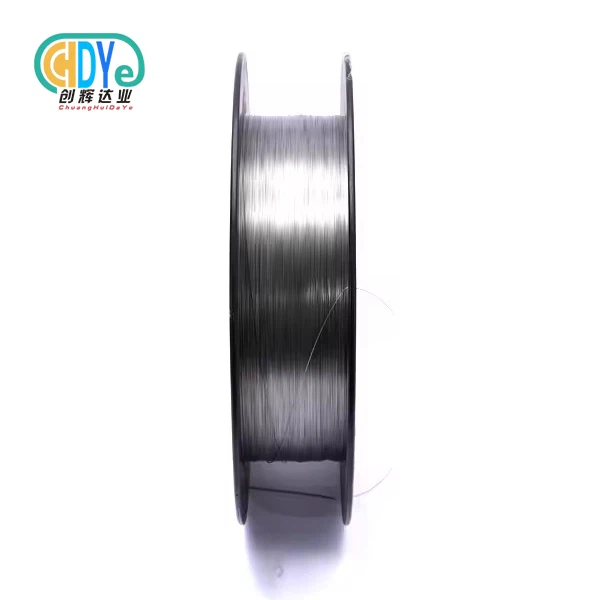

Titanium welded pipe is a precision-engineered product made by rolling and welding titanium sheets or strips under strictly controlled conditions. It provides an excellent combination of light weight, corrosion resistance, and structural strength, making it ideal for cost-efficient industrial applications.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. manufactures titanium welded pipes using state-of-the-art TIG and plasma welding technology to ensure superior weld integrity and smooth surface finishes. Our products fully comply with ASTM B338, ASTM B861, and ASME SB-338 standards, meeting the highest expectations of global customers in the chemical, marine, and aerospace industries.

Titanium welded tube are light, strong and have excellent mechanical properties, they are widely used in heat exchange equipment such as shell and tube heat exchangers, coil heat exchangers, serpentine heat exchangers, condensers, evaporators and pipelines. Many nuclear power industries use titanium pipes as standard tube for their units.

Chdymetal can supply large diameter titanium welded pipe, if you need customized service pls feel free to contact us.

|

Product name |

Titanium welded pipe |

|

Standard |

ASTM B862, ASTM B338 |

|

Material |

Pure titanium/Titanium alloy |

|

Color |

Sliver grey |

|

Grade |

Gr1,Gr2,Gr5,Gr7,Gr9,Gr10,Gr12 |

|

Feature |

Fine Corrosion Resistance/Light |

|

Technique |

Welded |

|

Tolerance |

OD(±0.1-±0.25)mm Length(±5-20)mm |

|

Outer Diameter |

Φ16-300 mm |

|

Inside Diameter |

≥15 mm |

|

Length |

≤18000mm |

|

Wall Thickness |

0.5mm-8mm |

|

Surface |

Pickling, Polished |

|

Packing |

Foam plastic inside, Ply-wooden box outside |

|

Shape |

Round/Square/Rectangle |

Titanium Welded Pip stock

Application Advantages

Titanium welded pipe is widely used in projects where corrosion protection, light weight, and economic efficiency are essential:

-

Chemical and Petrochemical Industry: Transporting acids, chlorides, and high-purity chemicals.

-

Marine and Offshore Engineering: Cooling systems, seawater desalination pipelines, and offshore platforms.

-

Aerospace Systems: Lightweight exhaust ducts and structural tubing.

-

Heat Exchangers & Condensers: Tubes for thermal equipment in refineries and power stations.

-

Environmental Engineering: Piping systems in waste treatment and seawater purification plants.

-

Pharmaceutical and Food Processing: Applications requiring non-toxic and hygienic materials.

The combination of reliability, corrosion resistance, and formability makes our titanium welded pipe an excellent choice across diverse sectors.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye operates a complete welding and fabrication line with advanced process control to ensure outstanding product quality:

- Sheet Forming: Titanium sheets are precisely rolled and edge-trimmed to ensure accurate pipe circumference.

- Automatic TIG Welding: Continuous inert gas protection minimizes oxidation and guarantees clean welds.

- Annealing & Straightening: Controlled heat treatment improves grain uniformity and ductility.

- Weld Inspection: 100% non-destructive testing using radiographic and ultrasonic methods.

- Finishing & Polishing: Internal and external surfaces are treated for enhanced smoothness and appearance.

Our production team ensures every weld is defect-free and meets international dimensional accuracy standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every titanium welded pipe produced by Shaanxi Chuanghui Daye undergoes rigorous quality control from raw material sourcing to final shipment.

We strictly follow ISO 9001:2015 and ASTM requirements to guarantee product consistency and traceability.

Main Quality Control Steps:

- Incoming material chemical analysis using spectrometers

- Weld seam visual and X-ray inspection

- Hydrostatic and pressure testing for leakage prevention

- Dimensional accuracy verification using advanced measuring systems

- Final visual examination and packaging inspection

A detailed inspection report is provided with every shipment, ensuring complete transparency and reliability.

OEM & Customization Services

We provide full customization to meet various industrial and engineering requirements:

-

Custom pipe dimensions and wall thicknesses

-

Specific welding types and surface treatments

-

Integration with flanges, elbows, or fittings

-

Special alloy combinations (Ti-Pd, Ti-Mo, Ti-Ni) for enhanced corrosion resistance

-

Engineering consultation for pipeline design and system optimization

Our engineers collaborate closely with customers to develop cost-effective titanium welded pipe solutions that meet project-specific challenges.

Packaging & Global Logistics

To ensure safe and efficient delivery worldwide, each titanium welded pipe is packaged with care:

- Inner Layer: Anti-rust plastic film or vacuum wrapping to protect surface finish

- Outer Layer: Plywood boxes, steel-framed crates, or bundled packing for large-diameter pipes

- Labeling: Includes grade, size, production batch, standard, and inspection status

- Delivery: Global logistics support via air, sea, or rail with full traceability

Our export packaging fully complies with international transport standards to prevent mechanical or corrosion damage.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Inspection Process

1) Appearance and dimension inspection to ensure every titanium welded pipe meets tolerances,no cracks, pits or other defects on the surface.

2) 100% Straightness inspection.

3).Non Destructive Testing offered

- Eddy Current Testing

- Ultrasonic Testing with full body thickness measurement

- Real Time Digital Radiography Testing

- Conventional Film Radiography

Why Choose Us

- Over 30 years of expertise in titanium and rare metal manufacturing

- ISO 9001-certified quality management and full inspection process

- Advanced automated welding and forming equipment

- OEM and ODM solutions for specialized applications

- Fast global delivery and flexible order quantities

- Supply to over 50 countries worldwide

- Dedicated after-sales service and technical assistance

Our consistent quality, reliability, and technical strength have made us a trusted supplier for global titanium material projects.

|

|

|

|

|

|

FAQs

Q1: What is the difference between titanium welded and seamless pipes?

A1: Welded pipes are formed by rolling and welding titanium sheets, offering larger diameters and cost efficiency, while seamless pipes provide higher pressure resistance.

Q2: What welding methods are used in production?

A2: We use TIG and plasma arc welding with argon protection for clean, high-strength weld seams.

Q3: Are the welds tested before shipment?

A3: Yes, every weld undergoes radiographic and hydrostatic testing to ensure defect-free quality.

Q4: Can titanium welded pipes be used for high-temperature service?

A4: Yes, depending on the alloy grade, they perform reliably up to 600°C under stable pressure conditions.

Q5: Do you support custom fabrication and bending?

A5: Certainly. We provide bending, flanging, and end-machining services as per customer drawings or specifications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1760924769851.jpg)