- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pure Tantalum Bar

More details information as below:

Product Introduction

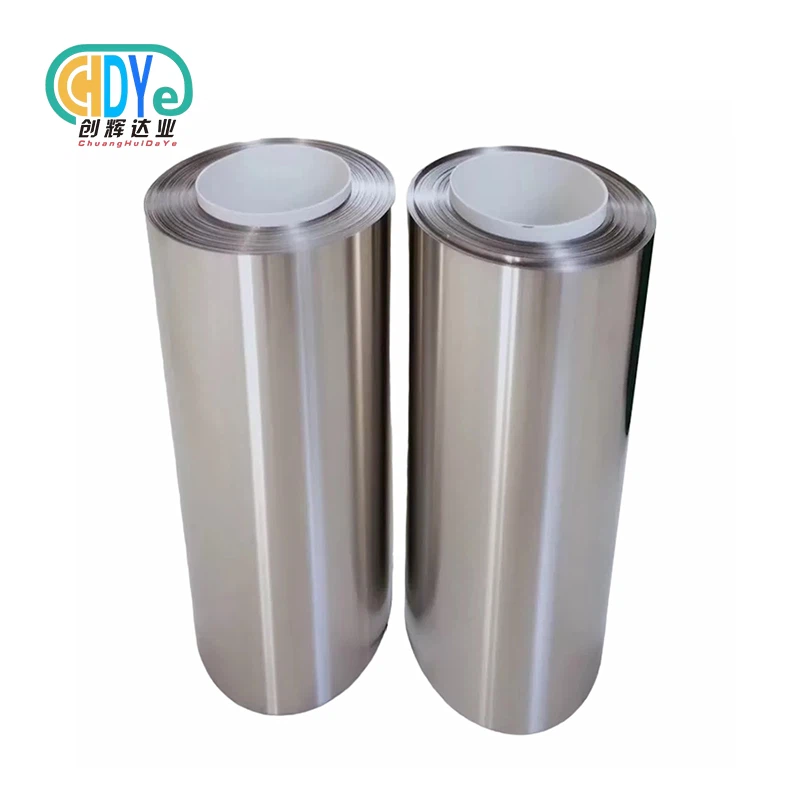

The Pure Tantalum Bar is a premium-grade refractory metal product characterized by excellent corrosion resistance, high melting point, and outstanding ductility. It is manufactured using high-purity tantalum (≥99.95%) and advanced processing techniques, ensuring uniform composition and fine-grained structure. Pure tantalum bars exhibit exceptional chemical stability in acidic and high-temperature environments, making them ideal for use in the chemical, electronic, aerospace, and medical industries. Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides Pure Tantalum Bars in various sizes and specifications according to ASTM B365 and other international standards. They are widely used in manufacturing furnace components, electrolytic capacitors, evaporation boats, and precision machining parts that require superior corrosion and heat resistance.

Chdymetal can offer pure tantalum bar with various purities and sizes. Tantalum bar have unique properties such as high melting point, corrosion resistance, and biocompatibility, making them the preferred material in medical, mechanical parts, aerospace, and laboratory equipment industries. Tantalum bar can be shaped in a tantalum round bar and tantalum square bar.

More details information as below:

Specification:

|

Product name |

Pure Tantalum bar |

|

Application |

Electronic Light Source Part;Implantation Parts.etc |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ2.0-100mm*L,customized |

|

Chemical Composition |

Pure Tantalum Rods/Bars |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

Chemcial Composition

|

Grade |

Chemical composition%, no more than |

|||||||||||

|

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

Ta |

|

|

Ta1 |

0.005 |

0.005 |

0.005 |

0.005 |

0.002 |

0.002 |

0.005 |

0.02 |

0.004 |

0.002 |

0.005 |

Balance |

|

Ta2 |

0.005 |

0.005 |

0.005 |

0.005 |

0.002 |

0.002 |

0.1 |

0.03 |

0.1 |

0.002 |

0.01 |

Balance |

Tantalum metal is stable in air at room temperature, when heated above 500 ° C, oxidation is accelerated to produce Ta205. Tantalum has a series of excellent properties such as high melting point, low steam pressure, good cold working performance, high chemical stability, strong resistance to liquid metal corrosion, and large dielectric constant of surface oxide film, and has important applications in high-tech fields such as electronics, metallurgy, steel, chemical industry, cemented carbide, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research.

Tantalum bar in stock

You can find the normal stock always and usually we can arrange delivery on the same day.we will also support your sample order.

|

Grade |

Standard |

Specification (mm) |

|

R05200 |

ASTM B 365 |

Dia 3.0*2300 |

|

R05200 |

ASTM B 365 |

Dia 5.0*L1000 |

|

R05200 |

ASTM B 365 |

Dia10mm*L1165-2340 |

|

R05200 |

ASTM B 365 |

Dia12.7*3010 |

|

R05200 |

ASTM B 365 |

Dia16-22*L1085-3000 |

|

R05200 |

ASTM B 365 |

Dia 25*L1000 |

|

R05200 |

ASTM B 365 |

Dia40*L1500 |

|

R05200 |

ASTM B 365 |

Dia 65*850 |

Application Advantages

1. Electronics: Used as electrode materials for capacitors.

2. Aerospace: Used to manufacture engine components and gas turbines.

3. Chemical industry: Used as an ideal material for handling strong acids and alkalis.

4. Medical: Used in the production of artificial joints and medical devices.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye Metal Material Co., Ltd. follows a precise and advanced production process to manufacture each Pure Tantalum Bar. The process includes raw material selection → electron beam melting → forging → rolling or drawing → heat treatment → surface finishing → inspection. Each stage is strictly controlled by professional technicians to guarantee uniform microstructure, excellent mechanical integrity, and precise dimensional tolerances. All production conforms to ASTM B365 and ISO 9001:2015 standards, ensuring consistent high quality for global clients.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Pure Tantalum Bar is subject to a comprehensive quality control system. Inspections include:

- Chemical composition testing to verify purity levels of ≥99.95%

- Ultrasonic inspection to detect internal flaws or inclusions

- Mechanical testing for tensile strength, elongation, and hardness

- Dimensional and surface inspection to ensure tight tolerance and smooth finish

- Inspection records are maintained for full traceability, guaranteeing products meet both international standards and customer-specific requirements.

R&D and Customization

With over 30 years of rare metal industry experience, Shaanxi Chuanghui Daye continuously advances its R&D capabilities to enhance product performance and processing efficiency. Customized Pure Tantalum Bar solutions are available for special applications requiring particular diameters, lengths, or surface finishes. Our team also supports prototype development, alloy modification, and process optimization to meet unique customer needs in vacuum, chemical, and semiconductor sectors.

Packaging & Global Logistics

Each Pure Tantalum Bar is packaged using export-grade protective materials to prevent oxidation and mechanical damage. Standard packaging includes vacuum sealing, anti-rust film wrapping, foam cushioning, and wooden cases. All shipments are clearly labeled with product specifications, heat numbers, and batch details. With reliable logistics partners and efficient air, sea, and land transportation networks, Shaanxi Chuanghui Daye ensures safe and timely global delivery to over 50 countries.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide comprehensive OEM and ODM services for global clients. Our customization capabilities include tailored dimensions, purity grades, and precision machining based on detailed drawings. From prototype development to mass production, we ensure consistent quality and fast lead times. Customers choosing Shaanxi Chuanghui Daye benefit from expert technical support, competitive pricing, and professional after-sales service for every Pure Tantalum Bar order.

Inspection Process

- Raw material verification – Checking chemical purity and certification

- Melting and forming inspection – Monitoring during EB melting and forging

- Dimensional control – Ensuring precision after rolling or drawing

- Mechanical testing – Measuring hardness and tensile properties

- Final inspection – Visual, ultrasonic, and surface finish verification

- Packaging review – Confirming compliance with export standards

Why Choose Us

- Over 30 years of expertise in rare and refractory metals

- ISO 9001:2015 certified quality management system

- In-house melting, forging, and precision machining capabilities

- Fast delivery for standard sizes within 7 days

- Trusted by customers in 50+ countries for quality and reliability

|

|

|

|

|

|

FAQs

Q1: What purity levels do you offer for the Pure Tantalum Bar?

A1: Standard purity is 99.95%, with ultra-high purity up to 99.99% available on request.

Q2: Can you supply custom diameters and lengths?

A2: Yes, we manufacture customized dimensions according to customer specifications or drawings.

Q3: Which standards do your products comply with?

A3: Our bars are produced in full compliance with ASTM B365 and ISO 9001:2015.

Q4: Do you provide material certificates?

A4: Yes, each batch comes with a complete inspection report and material test certificate.

Q5: What is the usual delivery time?

A5: Standard products are shipped within 7 days; custom orders depend on quantity and specifications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1760924529645.jpg)