- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

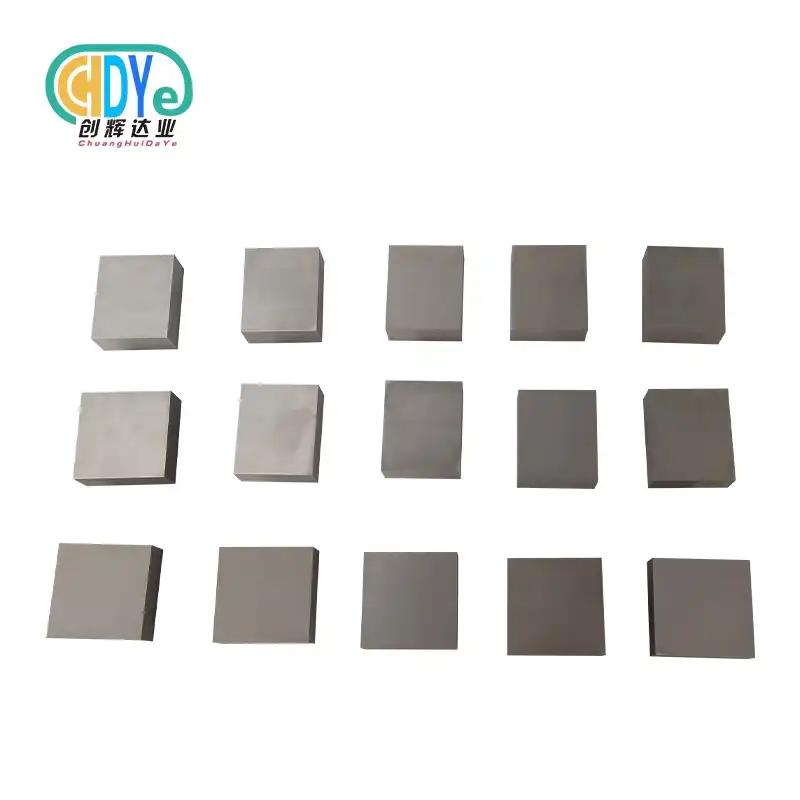

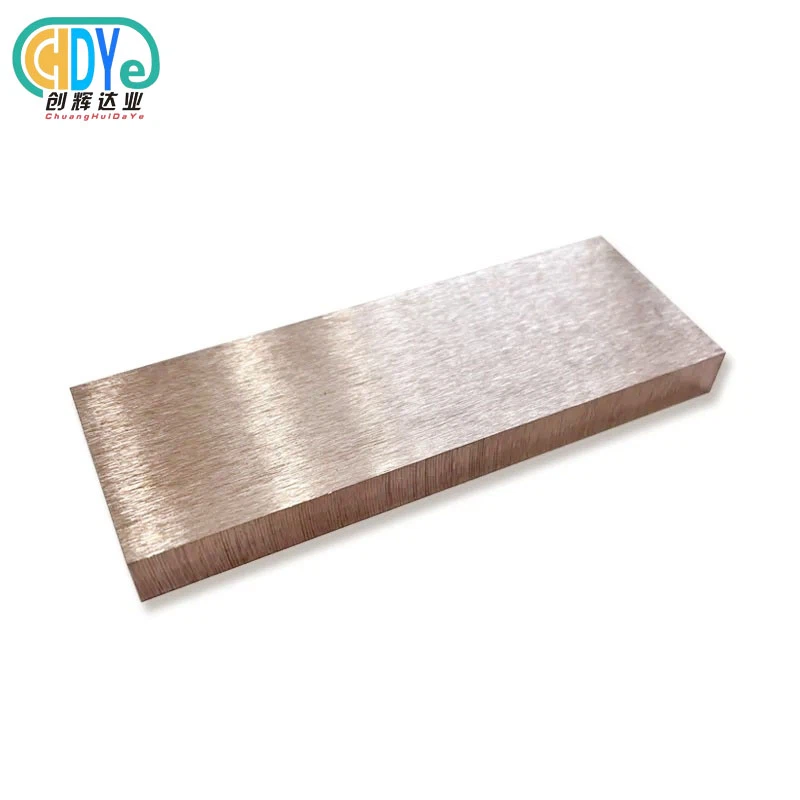

Tungsten Metal Plate

2.Surface treatment: black, alkali washing, ground

3.Size: As your request

Product Introduction

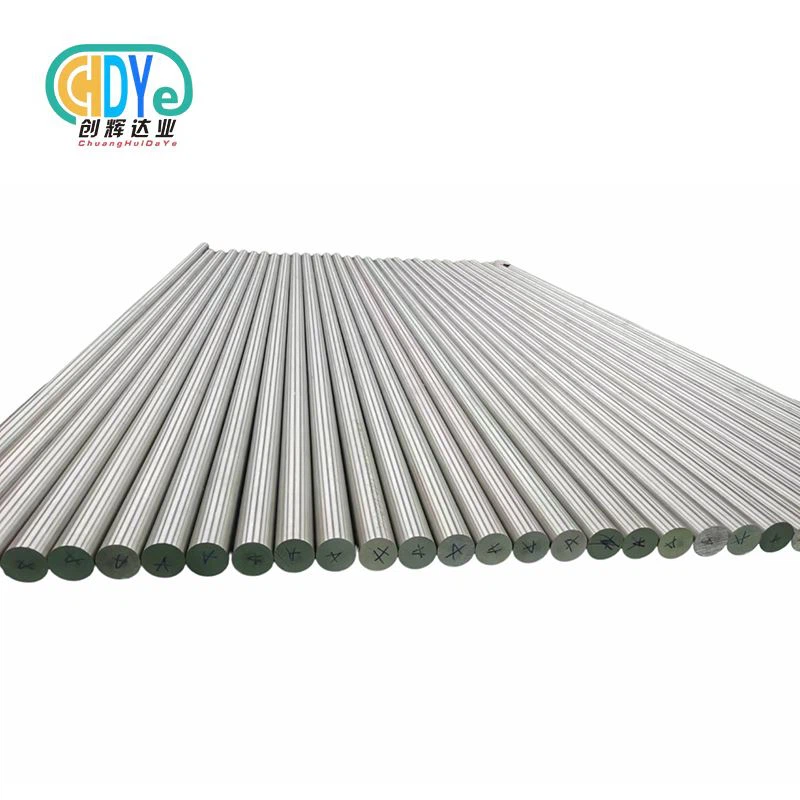

The Tungsten Metal Plate manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a premium-grade refractory metal product designed for high-temperature, high-strength, and high-density applications. With exceptional thermal conductivity, low vapor pressure, and outstanding corrosion resistance, this product performs reliably under extreme operating environments. Produced from ultra-high-purity tungsten through advanced powder metallurgy and rolling techniques, each plate offers uniform structure, excellent flatness, and superior mechanical stability. The company adheres to international standards such as ASTM, GB, and ISO to ensure that every plate meets or exceeds industry performance requirements. This makes it ideal for use in aerospace, electronics, vacuum furnaces, and metallurgical equipment manufacturing.

Specifications

1.Material: pure tungsten and tungsten alloy

2.Surface treatment: black, alkali washing, ground

Application Advantages

1.Vacuum equipment: Tungsten plates are widely used in vacuum equipment manufacturing, such as vacuum furnaces, vacuum tubes, vacuum electronic devices, etc., due to their high melting point, low evaporation rate and excellent thermal stability.

2. High temperature applications: Tungsten plates can maintain structural stability in high temperature environments, so they are used as thermal insulation shielding materials, furnaces and hearths of high temperature furnaces, etc.

3. Electrode materials: Tungsten plates are used as electrode materials, such as EDM electrodes, electrode sheets and electrode plates. Due to the high melting point, low ablation rate and high thermal conductivity of tungsten, tungsten plates can withstand high-energy discharges and have good durability and stability.

4. Alloy preparation: Tungsten plates are often alloyed with other metals to improve their mechanical properties, thermal properties and corrosion resistance. Tungsten alloys are widely used in aerospace, automobile manufacturing, electronic devices and other fields.

Protective materials: Due to the high density and high hardness of tungsten, tungsten plates are used as protective materials, such as tank armor, bulletproof materials and ballistic shields. They are able to provide effective protection, absorb and disperse impact and energy.

5. X-ray and radiation protection: Tungsten plates are used as X-ray or radiation protection materials due to their high density and high atomic number, such as in medical imaging (such as CT scanning equipment), industrial radiation protection and nuclear medicine.

6. Petroleum and chemical industry: Tungsten plates are used in the petroleum and chemical industry to manufacture catalyst carriers, reactors, distillation towers and high-temperature reactors, etc.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

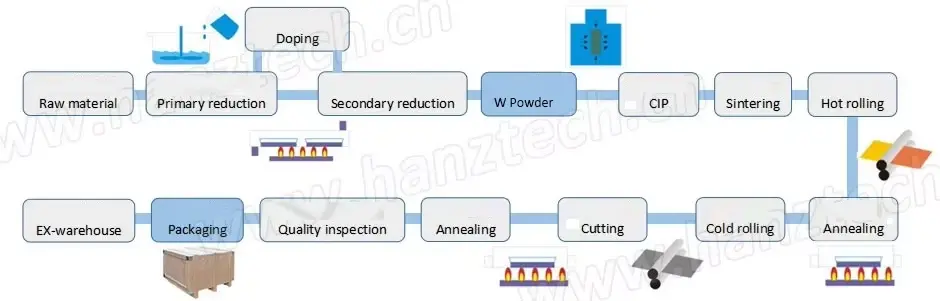

Manufacturing & Process Flow

|

|

|

|

|

|

|

|

Quality Control & Inspection

At Shaanxi Chuanghui Daye, quality management is embedded in every production phase. The Tungsten Metal Plate undergoes comprehensive inspections to ensure it meets ISO 9001:2015 standards.

Inspection Procedures Include:

- Raw material purity and particle size analysis

- Density and porosity testing

- Tensile and hardness evaluation

- Surface flatness and thickness tolerance verification

- Ultrasonic and visual inspection for defects

- Conductivity and oxidation resistance testing

Each plate is traceable through a unique batch number, ensuring complete documentation of its manufacturing and testing history.

R&D and Customization

Shaanxi Chuanghui Daye continuously invests in research and development to enhance material performance and expand application fields. The company’s R&D team can customize Tungsten Metal Plate specifications based on client requirements, such as size, thickness, purity, and grain orientation. Special coatings, surface polishing, and alloying modifications are available to improve corrosion resistance and workability. Through collaborations with research institutes and industrial clients, we provide tailored tungsten solutions that optimize performance in critical aerospace, semiconductor, and thermal management systems.

Packaging & Global Logistics

Each Tungsten Metal Plate is carefully packed to maintain its quality and integrity during transport. Packaging materials include vacuum-sealed anti-rust film, foam protection, and export-grade wooden cases that comply with international shipping standards.

Logistics Services:

- Air freight for small-volume or urgent orders

- Sea freight for large-scale industrial shipments

- Land transport for domestic and regional deliveries

All shipments are clearly labeled with product details, batch numbers, and inspection certificates. Our global logistics partners ensure efficient and secure delivery to over 50 countries, including the USA, Germany, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

We offer professional OEM and ODM services to meet diverse customer demands. Clients can specify customized compositions, dimensions, and surface finishes for their tungsten materials. Our technical team provides guidance throughout the design and production stages, including prototype development, performance testing, and packaging. Shaanxi Chuanghui Daye is committed to delivering high-quality, cost-effective Tungsten Metal Plate solutions for manufacturers in electronics, aerospace, and metallurgical sectors.

Inspection Process

Our inspection workflow ensures full compliance with international standards and customer requirements:

- Raw Material Verification: Purity testing and particle size control.

- Intermediate Process Inspection: Monitoring density, sintering temperature, and rolling precision.

- Dimensional Accuracy: Precision measurement using advanced CMM instruments.

- Mechanical Testing: Evaluation of tensile strength, hardness, and ductility.

- Final Visual and Ultrasonic Check: Detection of cracks, inclusions, or surface irregularities.

Only products passing all quality assessments are approved for packaging and export.

Why Choose Us

- Over 30 Years of Industry Expertise in rare and refractory metal manufacturing.

- ISO 9001:2015 Certified Quality System ensuring full traceability and product reliability.

- Advanced Equipment including electron beam furnaces, rolling mills, and CNC machining centers.

- Global Market Reach with customers in more than 50 countries.

- Customized Solutions for demanding engineering and research applications.

- Fast and Reliable Delivery supported by a professional logistics network.

|

|

|

|

|

|

FAQs

Q1: What are the standard sizes of Tungsten Metal Plate available?

A1: Thickness ranges from 0.3 mm to 50 mm, with custom dimensions available upon request.

Q2: What purity levels do you offer?

A2: Standard purity is 99.95%, while ultra-high purity grades up to 99.99% can be provided for specialized use.

Q3: How is the surface of the plate finished?

A3: Surfaces are typically polished, ground, or machined according to customer specifications.

Q4: Can small-batch production be arranged?

A4: Yes, prototype and small-batch orders are available for research and development applications.

Q5: What is the delivery time for standard orders?

A5: Regular sizes are delivered within 7–10 working days, while customized orders depend on specific requirements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email