- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

MMO Ribbon Anode

Product Introduction

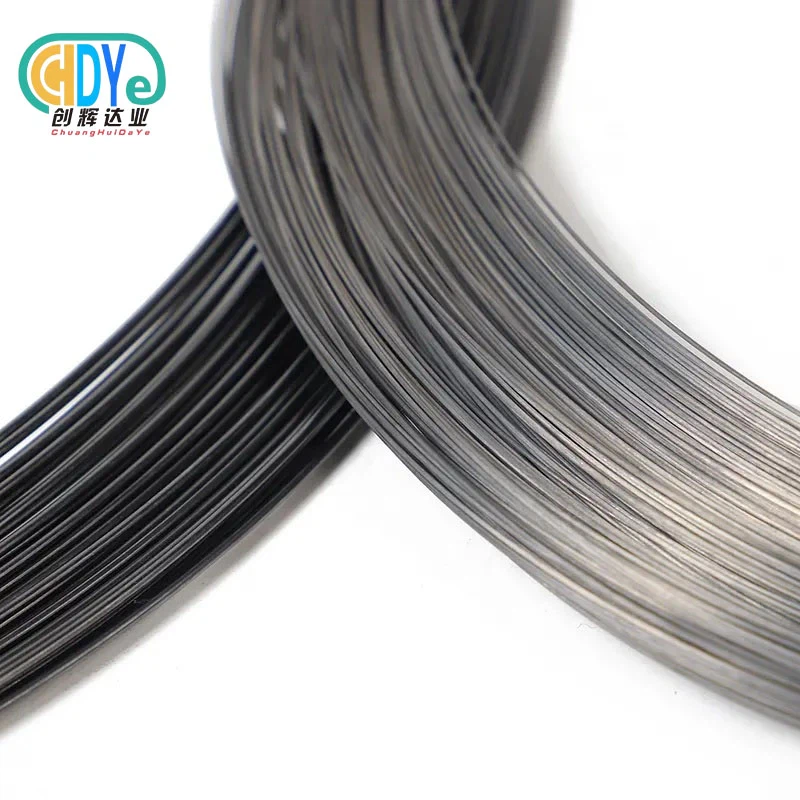

Precious metal oxide anode is composed of a layer of metal oxide with electrocatalytic activity (oxides of metals such as ruthenium, iridium, and titanium) covering a titanium substrate (ASTMB 265 grade titanium). The oxide coating has low polarization and extremely low consumption rate. By adjusting the composition of the oxide layer, it can be adapted to different environments, such as seawater, freshwater, and soil media. Due to the advantages that other anodes do not have, precious metal oxide anode has become the most ideal and promising auxiliary anode material currently available.

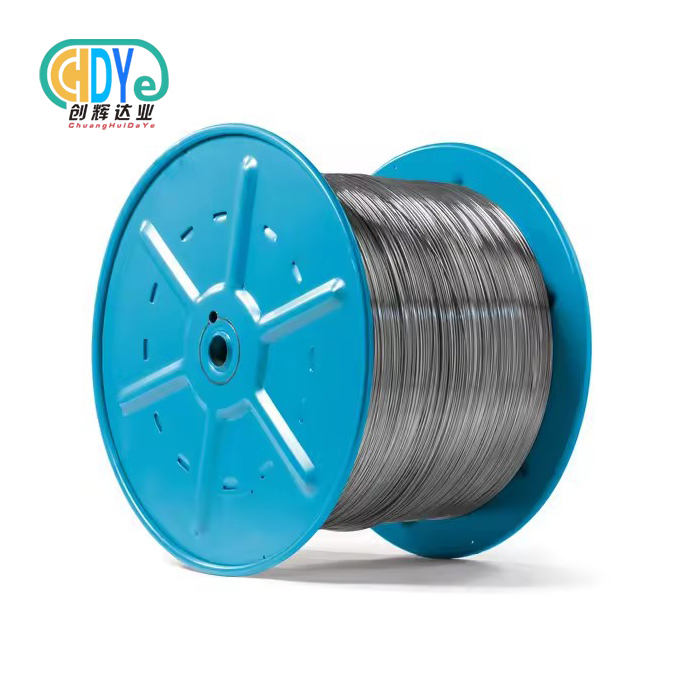

MMO Ribbon Anodes common size

|

Width(mm) |

Thickness(mm) |

Length(m) |

Current |

Expected life(a) |

|

6.35 |

0.635 |

152/155 |

17 |

50 |

|

6.35 |

0.635 |

152/155 |

42 |

50 |

Working environment:Seawater, the main anode product is Cl2; Soil, freshwater, brackish water, seawater, with anodic products mainly consisting of O2 or Cl2 or both.

Related products

Application Advantages

1. Anti corrosion of pipeline inner wall

2. Underground storage tank, ground storage tank, water storage tank

3. Condensed water tank, heat exchanger, water treatment equipment

4. Corrosion prevention of ships, roads, bridges, and building steel structures

5. Continuous horizontal ground bed, discontinuous horizontal ground bed, shallow buried vertical ground bed

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

The MMO Ribbon Anode is produced under precise control using high-purity titanium base materials and advanced coating technology.

Production Flow:

- Material Selection – Only titanium plates meeting ASTM B265 (Grade 1 or 2) standards are chosen.

- Surface Preparation – Titanium surfaces undergo degreasing, pickling, and sandblasting for maximum adhesion.

- MMO Coating Application – A mixed metal oxide layer (typically RuO₂ + IrO₂ or IrO₂ + Ta₂O₅) is evenly applied.

- High-Temperature Sintering – Coating is bonded permanently to the titanium surface through thermal treatment.

- Precision Cutting & Shaping – Ribbon is processed to required width and thickness.

- Final Testing – Coating uniformity, adhesion strength, and electrical performance are tested.

- Packaging & Storage – Completed anodes are sealed to prevent contamination before delivery.

Each production stage is handled by experienced technicians to ensure long-term stability and consistency.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is central to Shaanxi Chuanghui Daye’s manufacturing philosophy. All MMO ribbon anodes undergo comprehensive inspections to ensure compliance with international standards.

Inspection Items Include:

- Chemical Composition Testing: Confirms titanium purity and coating composition.

- Coating Thickness Measurement: Ensures even distribution and strong adhesion.

- Adhesion & Peel Test: Guarantees coating durability during extended operation.

- Electrochemical Testing: Measures current density, potential, and consumption rate.

- Dimensional Accuracy: Verifies ribbon width, thickness, and straightness.

- Corrosion Resistance Test: Simulates seawater and soil environments.

All testing is performed under ISO 9001:2015 quality management requirements, with traceable documentation for every batch.

R&D and Customization

Shaanxi Chuanghui Daye continuously advances its MMO coating technology through in-house R&D. Our research team focuses on developing improved coating compositions and extended service life solutions.

Customization Capabilities Include:

- Custom ribbon width and thickness (e.g., 6.35 mm × 0.635 mm, 12.7 mm × 0.9 mm, etc.)

- Adjustable coating composition (Ru-Ir, Ir-Ta, Ru-Ti, etc.)

- Tailored current output and design life based on client environment

- Integration with copper conductors, junction boxes, or connectors

- Engineering design support for complex cathodic protection systems

We provide technical consultation to ensure each anode perfectly matches the client’s application and performance targets.

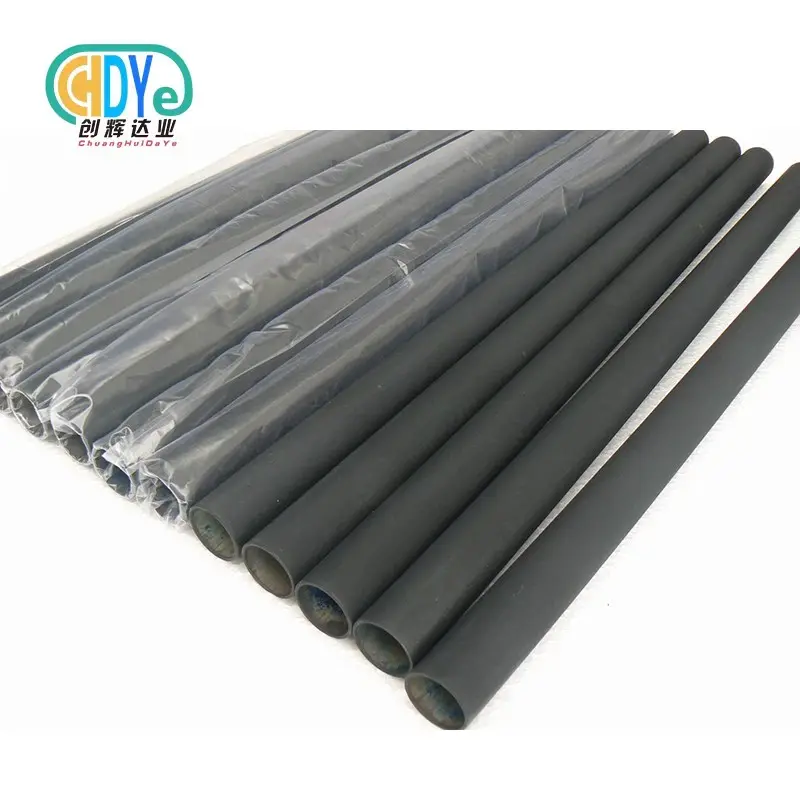

Packaging & Global Logistics

All products are packed following international export standards to ensure product integrity and safe delivery.

Packaging Details:

- Inner Protection: Anti-static or vacuum-sealed film with foam layers.

- Outer Case: Export-grade plywood boxes or reinforced cartons.

- Labeling: Includes product name, size, batch number, coating type, and manufacturing date.

- Transportation: Supports sea, air, and land shipment with reliable global logistics partners.

- Delivery Time: Standard lead time within 7 working days for most orders.

Each shipment includes an inspection report and traceability certificate for quality assurance.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers professional OEM/ODM cooperation for global clients in the cathodic protection and chemical industries.

Service Scope:

- Custom branding and packaging

- Tailored product specifications for engineering firms and system integrators

- Rapid prototyping and small-batch production

- Technical consultation and installation guidance

- Full documentation support (Material Certificate, Inspection Report, ISO Certification)

We aim to build long-term partnerships through reliability, precision, and flexibility.

Inspection Process

- Incoming Material Verification – Titanium base and coating chemicals are tested.

- In-Process Control – Coating temperature and thickness monitored in real-time.

- Adhesion & Electrical Testing – Ensures coating strength and electrical performance.

- Visual & Dimensional Inspection – Confirms appearance and tolerance compliance.

- Final Testing & Documentation – Quality certificate issued for each batch.

Each MMO ribbon anode is fully traceable from raw material to final delivery.

Why Choose Us

- 30+ Years of Industry Expertise in titanium and rare metal manufacturing

- Comprehensive Quality Control under ISO 9001:2015 certification

- Advanced Equipment: Electron beam furnace, rolling mill, and coating systems

- Customized Solutions: Designed to meet diverse industrial requirements

- Fast Global Delivery: 7-day lead time for standard products

- 30+ Export Markets: Trusted by clients across North America, Europe, and Asia

- Technical Support & After-Sales Service: Professional guidance from material to application

|

|

|

|

|

|

FAQs

Q1: What is the typical lifespan of an MMO Ribbon Anode?

A1: Depending on the environment and current density, the lifespan ranges from 20 to 50 years.

Q2: What coating compositions are available?

A2: We offer Ru-Ir, Ir-Ta, and Ru-Ti oxide coatings, tailored to your operating conditions.

Q3: Can I request a custom ribbon width or thickness?

A3: Yes, we can produce ribbon anodes in any dimension according to your design drawings.

Q4: Are these anodes suitable for seawater applications?

A4: Absolutely. The MMO coating provides excellent resistance to chloride corrosion in seawater environments.

Q5: Do you provide installation support?

A5: Yes, we can offer engineering advice, technical drawings, and project recommendations upon request.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email