- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

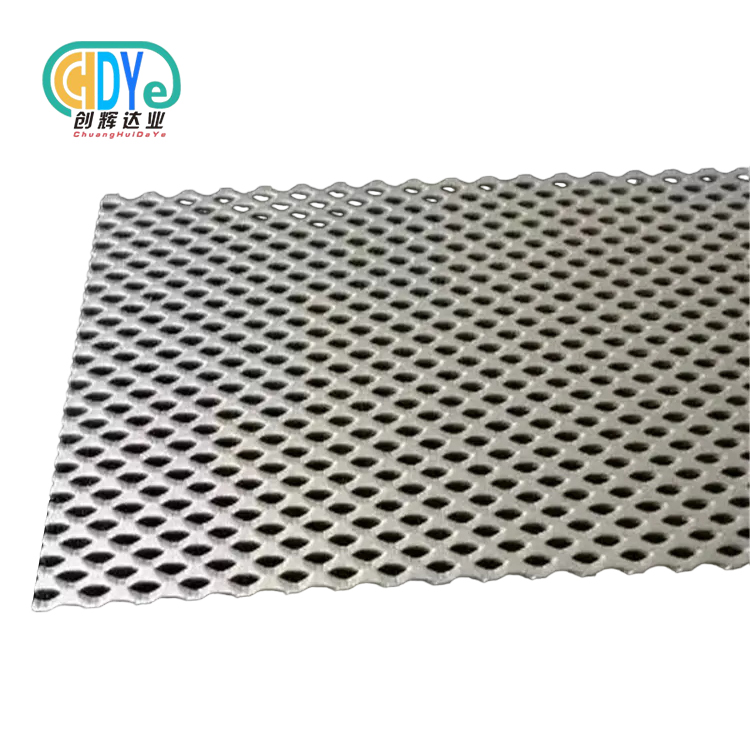

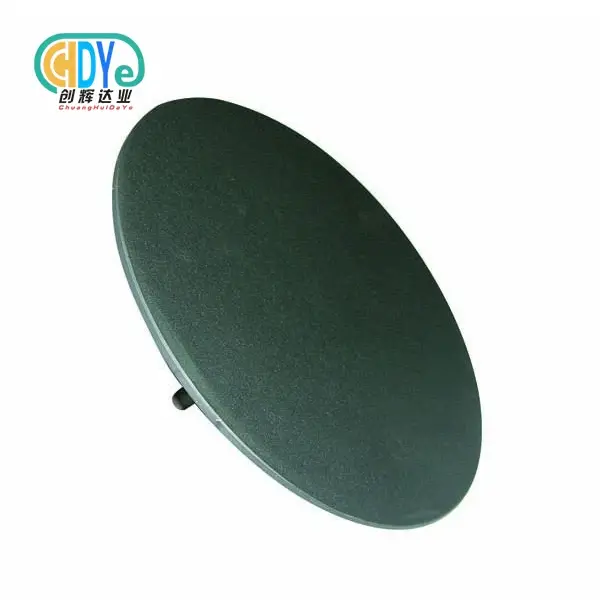

Titanium Mesh Anode

Product Introduction

Chdymetal can provide various titanium anodes, customized is accepted. titanium anode use pure titanium material as substrate, has high anti-corrosion and high catalytic activity. MMO coated anode titanium mesh has long working life .For the important, the substrate could be reused.

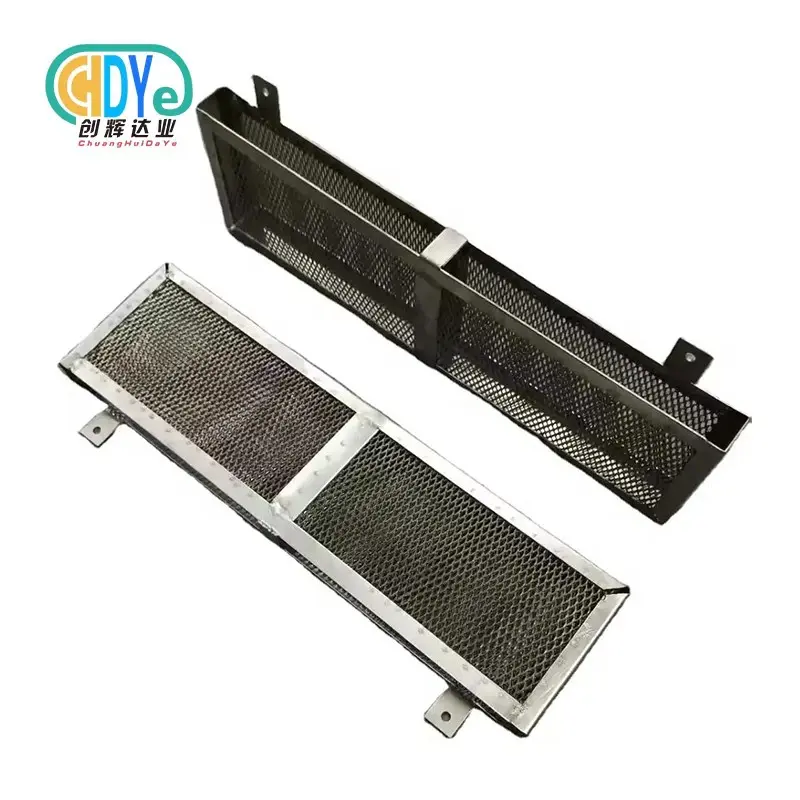

Titanium mesh anode is used in water electrolysis, sewage treatment, caustic soda, cathodic protection, Chlor alkali industry, chlorine dioxide production, chlorate industry, hypochlorite industry, wastewater recovery, persulfate production, waste recycling of zinc plating plants, electrowinning, and food appliance sterilization.

SPecification:

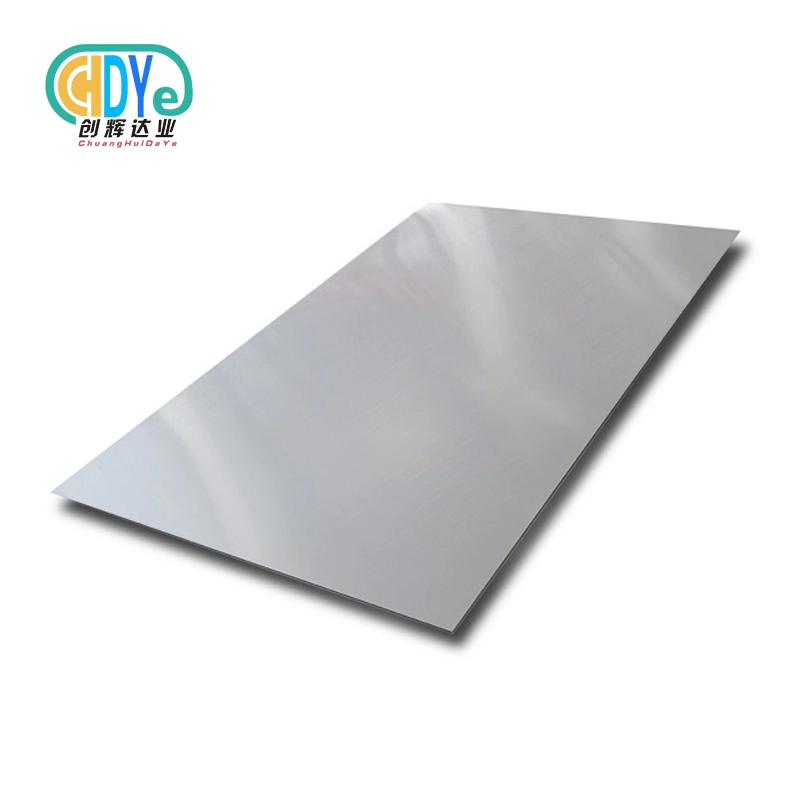

1. Mterial : Gr1 titanium as substrate,

2.Coating type: RuO2, IrO2, Plating, and PbO2

3. Mesh type: common mesh hole :12.5*4.5mm,5*10mm,3*6mm

4. Payment methods: 30%TT in advance, 70% balance before shipment.

5. Delivery time: normal production time 7-10 days

Related products

Application Advantages

Titanium Mesh Anode is widely used in electrochemical applications due to its superior corrosion resistance, excellent electrical conductivity, and long service life. Designed with a lightweight mesh structure, it ensures uniform current distribution and enhanced electrolysis efficiency.

Key Application Benefits:

- High Current Efficiency: Ensures stable electrochemical reactions and consistent product quality.

- Outstanding Corrosion Resistance: Ideal for use in harsh chemical environments such as seawater, chlorine, and acidic solutions.

- Extended Service Life: Significantly reduces replacement frequency and maintenance costs.

- Uniform Current Distribution: Improves plating uniformity and surface smoothness.

- Energy-Saving Performance: Reduces voltage loss during electrolysis, enhancing operational efficiency.

- Wide Industrial Use: Applied in electroplating, wastewater treatment, electrochlorination, and cathodic protection systems.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Our Titanium Mesh Anodes are manufactured under rigorous process control, ensuring precision and reliability at every step.

Production Workflow:

- Raw Material Selection: High-purity Grade 1 or Grade 2 titanium base material is carefully selected.

- Mesh Forming: Titanium sheets are expanded or woven into precise mesh patterns according to design requirements.

- Surface Treatment: Cleaning, degreasing, and sandblasting are applied for optimal coating adhesion.

- Coating Application: Advanced coating techniques such as brush, dip, or thermal decomposition are used to apply Ru-Ir, IrO₂, or Pt coatings.

- Thermal Treatment: Controlled heat treatment to ensure strong coating adhesion and electrochemical stability.

- Testing & Inspection: Electrical, dimensional, and coating thickness tests ensure all standards are met.

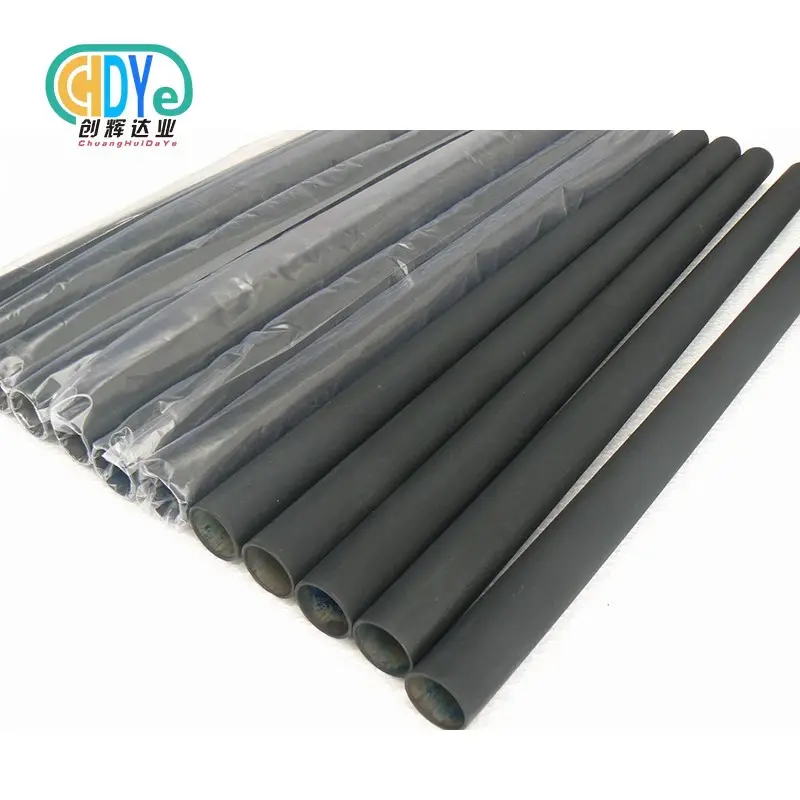

- Final Packaging: Each anode is vacuum-sealed and prepared for international shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is the foundation of Shaanxi Chuanghui Daye’s competitiveness. We strictly follow the ISO 9001:2015 quality management system from material procurement to final shipment.

Inspection Stages Include:

- Incoming Material Inspection: Verification of titanium grade, purity, and mechanical properties.

- Process Monitoring: Continuous supervision during mesh forming and coating to maintain consistency.

- Coating Quality Test: Evaluation of coating thickness, composition, and adhesion.

- Electrochemical Testing: Measurement of potential stability and coating performance.

- Final Dimensional Check: Ensures compliance with ASTM and GB standards.

Each product comes with complete test reports and traceability documentation.

R&D and Customization

Our in-house R&D team focuses on developing high-performance titanium anodes with enhanced electrochemical characteristics.

Research & Innovation Focus:

- Development of new mixed-metal oxide coatings for longer service life.

- Custom coating formulations for specific electrolytes and current densities.

- Prototyping and small-batch development for specialized applications.

- Continuous improvement based on client feedback and industrial advancements.

Customization Options:

- Mesh size, wire diameter, and coating type (Ru-Ir, IrO₂, Pt, Ta-Ir).

- Titanium grade (Gr1, Gr2) and substrate thickness.

- Shape and dimensions tailored to reactor or cell design.

Packaging & Global Logistics

To ensure product integrity during transport, Shaanxi Chuanghui Daye applies export-grade packaging methods and trusted logistics partnerships.

Standard Packaging:

- Vacuum or anti-rust film wrapping

- Shock-absorbing foam lining

- Fumigation-free wooden boxes

Global Delivery:

- Reliable shipping via air, sea, and land

- Fast dispatch within 7 days for standard products

- Real-time tracking for international shipments

All shipments comply with international packaging and labeling standards, guaranteeing safe arrival worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer flexible OEM and ODM services to meet your unique requirements.

Our Service Scope Includes:

- Custom mesh dimensions and coating compositions

- Private labeling and branding

- Prototype development and technical drawings

- Engineering support for product design optimization

Our technical team collaborates closely with clients to deliver reliable and cost-effective titanium mesh anodes for both standard and complex applications.

Inspection Process

To maintain consistency and high quality, each Titanium Mesh Anode undergoes a detailed inspection procedure before dispatch:

- Material Verification – Confirm titanium grade and purity.

- Dimensional Inspection – Check mesh pattern, thickness, and tolerance.

- Surface Examination – Detect coating uniformity and surface defects.

- Adhesion Testing – Evaluate bond strength between titanium substrate and coating.

- Performance Testing – Assess electrochemical stability under simulated conditions.

- Final Approval – Only 100% qualified products proceed to packaging and shipment.

Why Choose Us

- 30+ Years of Expertise: Founded by a rare metal industry veteran with decades of experience.

- ISO 9001 Certified Quality System: Full traceability and international compliance.

- Comprehensive Product Range: Titanium, Tantalum, Niobium, Tungsten, and Molybdenum materials.

- Strong R&D Capability: Innovative coating technologies and customized anode solutions.

- Global Reputation: Trusted by clients in 50+ countries including the USA, Germany, and South Korea.

- Fast Delivery: 7-day shipping for standard products and timely order fulfillment.

- Reliable After-sales Support: Responsive technical and service assistance for every order.

|

|

|

|

|

|

FAQs

Q1: What coating types are available for Titanium Mesh Anode?

A1: We offer a variety of coatings, including Ru-Ir, IrO₂, Pt, and mixed metal oxides tailored to specific electrochemical processes.

Q2: Can you produce custom mesh sizes or shapes?

A2: Yes. Mesh size, wire thickness, and overall dimensions can be customized based on your design drawings or operational needs.

Q3: How long is the service life of your Titanium Mesh Anode?

A3: Depending on the coating type and application environment, service life typically ranges from 2 to 10 years or longer.

Q4: Do you provide testing reports with shipments?

A4: Absolutely. Each batch is accompanied by a detailed inspection report, including chemical composition, coating thickness, and performance test results.

Q5: What is your minimum order quantity (MOQ)?

A5: We support both sample orders and bulk procurement, ensuring flexibility for R&D and large-scale applications.

Q6: How can I get a quotation quickly?

A6: Please send your requirements—drawing, coating type, and quantity—to info@chdymetal.com. Our team will respond within 24 hours.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email