- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Tantalum Rods and Bars

Welcome to contact us if you have any requirements.

Product Introduction

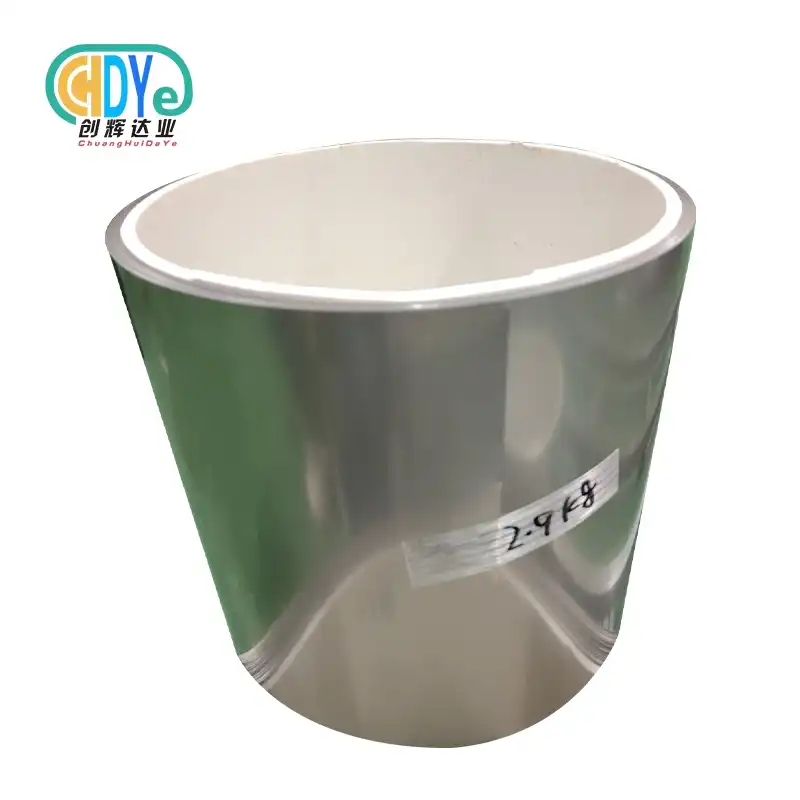

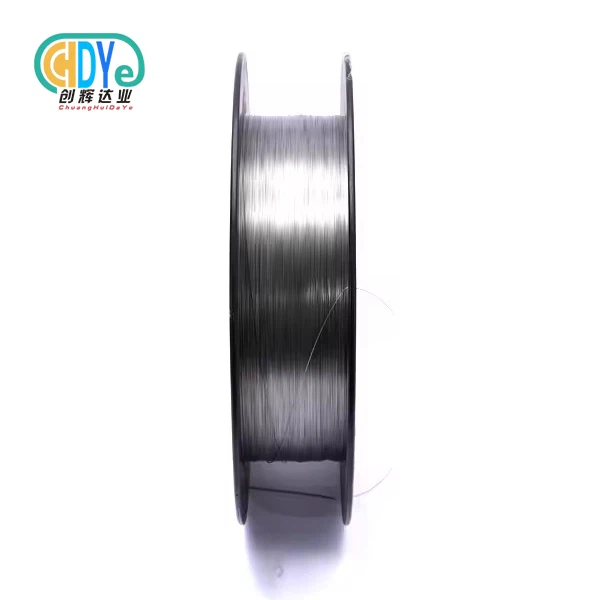

The Tantalum Rods and Bars produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd. are high-purity refractory metal products designed for applications requiring superior corrosion resistance, excellent thermal conductivity, and high strength under extreme conditions. Manufactured from premium-grade tantalum ingots, our Tantalum Rods and Bars conform to ASTM B365 and other international standards, ensuring consistent quality and dimensional precision. With outstanding chemical stability against strong acids such as hydrochloric and sulfuric acid, these products are widely used in chemical processing, aerospace, electronics, and medical industries.

Chdymetal offers top-quality Tantalum rods and bars at competitive prices with purities of 99.95% and 99.99%, providing customization service to meet specific needs. Tantalum and tantalum alloys possess a range of outstanding properties, including high melting point, low vapor pressure, excellent cold workability, high chemical stability, strong resistance to liquid metal corrosion, and a high dielectric constant of the surface oxide film. so they have significant applications in high-tech fields such as electronics, metallurgy, steel production, chemical industry, aerospace, medical and healthcare, as well as scientific research.

Tantalum rods and bars specification

|

Product name |

Tantalum rods and bars |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ2.0-100mm*L,customized |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

|

Packing term |

Foam packing inside, wooden box outside |

|

Delivery time |

Stock size within 1-5 days normal production time about 15 days |

|

Express |

DHL,Fedex, TNT by air,by sea |

|

Payment term |

30%TT in advance,70% balance before shipment |

Application Advantages

The Tantalum Rods and Bars offer unmatched advantages in high-performance environments:

- Excellent resistance to strong acids and oxidation

- High melting point (over 2996°C) with stable mechanical properties

- Superior ductility and formability for machining and fabrication

- Ideal for heat exchangers, electrodes, vacuum furnace parts, and medical implants

- Long service life and minimal maintenance requirements in corrosive media

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye adopts a complete production chain for Tantalum Rods and Bars, from raw material selection to precision machining.

Process Flow:

- Raw material selection and purity testing

- Electron beam melting or vacuum arc remelting

- Hot forging and rolling for structural uniformity

- Intermediate annealing for stress relief

- Precision grinding, machining, and surface finishing

- Final inspection and protective packaging

Each stage is executed under strict control to ensure superior density, smooth surface finish, and compliance with client specifications.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is central to our operations.

We are ISO 9001:2015 certified and maintain a full traceability system for all titanium seamless tube production. Every step—from raw material inspection to final delivery—is carefully monitored to ensure product reliability and compliance.

Comprehensive testing methods include:

- Mechanical property tests (tensile, yield, elongation)

- Non-destructive testing (ultrasonic and eddy current)

- Dimensional and visual inspections

- Corrosion resistance and metallographic analysis

Only after passing all evaluations are products released for shipment.

R&D and Customization

We maintain a rigorous ISO 9001:2015 quality management system to guarantee the performance and reliability of Tantalum Rods and Bars.

Inspection Procedures Include:

- Raw material analysis using spectrometers

- Ultrasonic and eddy current flaw detection

- Dimensional and surface finish inspection

- Mechanical and tensile strength testing

- Final packaging verification and batch traceability

All inspection records are archived for full traceability and customer assurance.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers full OEM and ODM support for global partners:

- Custom dimensions, drawings, and grades

- Branding and private labeling services

- Technical consultation and product development

- Fast turnaround and responsive after-sales service

Our experienced engineers can collaborate directly with your team to design optimized tantalum solutions for your specific applications.

Inspection Process

- Raw material chemical composition test

- Microstructure and grain uniformity analysis

- Ultrasonic flaw detection

- Surface finish and size measurement

- Packaging inspection and labeling confirmation

Every Tantalum Rods and Bars batch undergoes these detailed inspections before shipment to ensure compliance with customer and international standards.

Why Choose Us

- 30+ Years Expertise: Deep industry knowledge in refractory and rare metals

- Advanced Equipment: Electron beam furnaces, rolling mills, and precision machining tools

- Global Market Reach: Exported to 50+ countries with a strong reputation

- Strict Quality Control: ISO 9001:2015 certified production

- Fast Delivery & Support: 7-day quick turnaround and professional technical assistance

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is your trusted partner for premium-grade Tantalum Rods and Bars, offering reliable quality, competitive pricing, and customized solutions.

|

|

|

|

|

|

FAQs

Q1: What standards do your Tantalum Rods and Bars comply with?

A1: Our products fully meet ASTM B365 and can also be supplied per AMS, GB, or ISO standards.

Q2: Can you produce customized sizes and tolerances?

A2: Yes, we can manufacture based on your specific dimensional and tolerance requirements.

Q3: What is your minimum order quantity (MOQ)?

A3: We accept both small prototype orders and bulk production runs.

Q4: How do you ensure product quality?

A4: Each production stage undergoes strict inspection, and all Tantalum Rods and Bars are delivered with quality certificates and test reports.

Q5: What are your payment and delivery terms?

A5: Flexible terms are available—typically T/T, L/C, or Western Union—with fast worldwide delivery options.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email