- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ASTM B365 Tantalum Alloy Wire

if you need customized service just contact us

Product Introduction

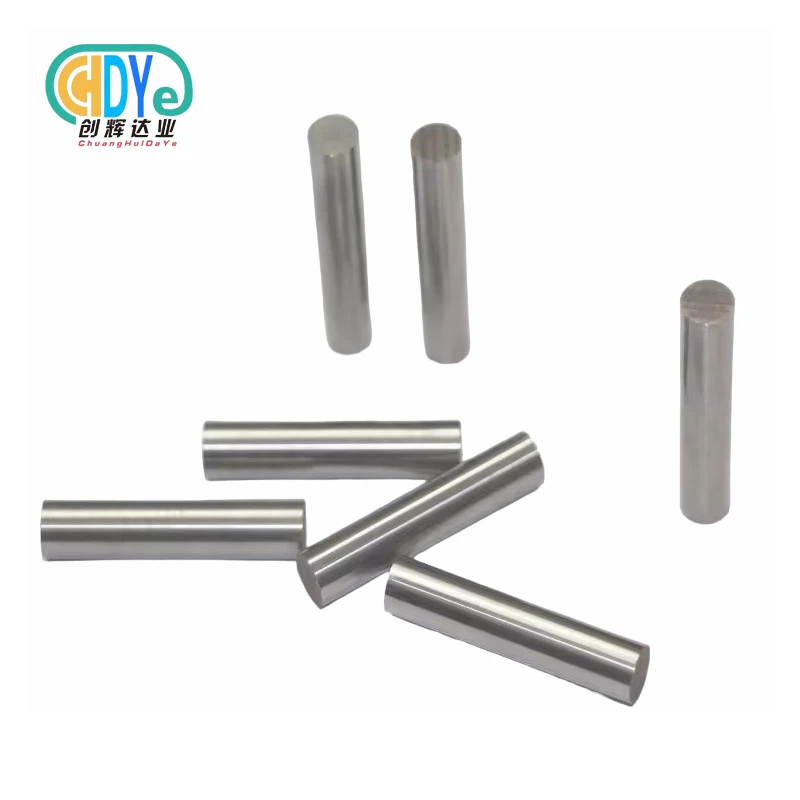

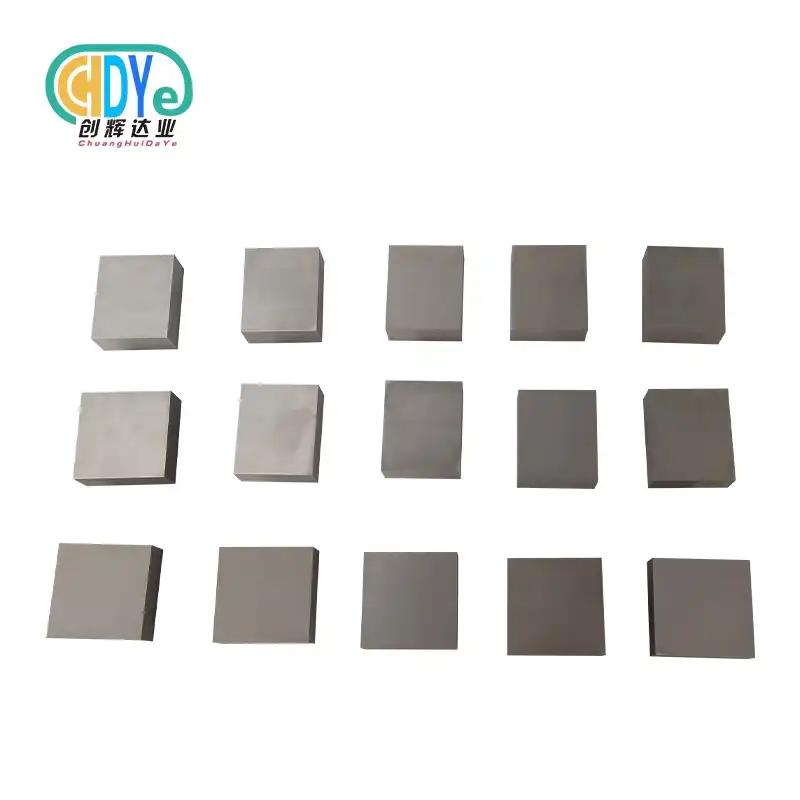

Chdymetal can offer ASTM B365 Tantalum Alloy Wire with various purities and sizes. Tantalum alloy wire is made according to ASTM B365 ,Tantalum Alloy wire Ta10W and Ta40Nb wire are part of our main product range.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces tantalum wire with precise dimensional tolerance, excellent mechanical properties, and consistent metallurgical structure. Each batch undergoes strict quality control to ensure stability, performance, and compliance with international standards such as ASTM, AMS, and ISO.

Our tantalum alloy wire is available in both pure and alloyed forms (Ta-2.5W, Ta-10W, etc.), offering enhanced strength and oxidation resistance while maintaining excellent workability for welding, drawing, and forming applications.

If you need customized service just contact us. More details information as below:

|

Product Name |

ASTM B365 Tantalum Alloy Wire |

|

Material |

Tantalum Niobium wire R05240 (Ta-40Nb) Pure tantalum: R05200, R05400; TantalumTungsten Rod / Bar R05252 (Ta-2.5W), R05255 (Ta-10W). |

|

Standard |

ASTM B365 |

|

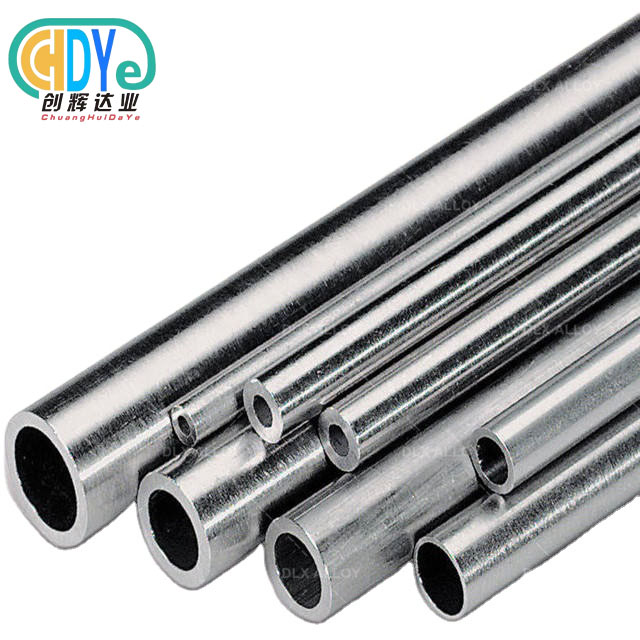

Size |

0.3-3mm |

|

Service |

Customized OEM, OEM/ODM/Customized, ODM Available |

|

Packing |

Wooden box |

|

Delivery time |

Stock size will be 1-5 days,normal production time is about 15 days |

|

Payment terms |

30%TT in advance,70% balance before shipment |

|

Condition |

Annealed / unannealed |

Tantalum and Tantalum Alloy UNS Grade

R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Other tantalum alloys also can be customized.

Key Features

- Excellent corrosion resistance to acids and alkalis

- High thermal and electrical conductivity

- Outstanding ductility and workability

- Uniform microstructure with smooth surface finish

- Available in spooled or straight lengths for flexible use

Technical Specifications

| Property | Specification |

|---|---|

| Standard | ASTM B365 |

| Material Grades | Pure Tantalum (Ta), Ta-2.5W, Ta-10W |

| Purity | ≥ 99.95% (Higher purity available upon request) |

| Diameter Range | 0.1 mm – 5.0 mm |

| Density | 16.6 g/cm³ |

| Melting Point | 2996°C |

| Tensile Strength | ≥ 200 MPa |

| Surface Condition | Polished, Cleaned, or Oxide-free |

| Delivery Form | Coil, Spool, or Straight Cut Lengths |

Application Advantages

Aerospace: Used for manufacturing high-temperature structural components and engine parts.

Chemical industry: Used as materials for corrosion-resistance equipment.

Electronic field: Used for producing capacitors and other electronic components.

Medical industry: Used for manufacturing artificial joints, dental implants, and other medical devices.

<

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye Metal Material Co., Ltd. follows a precision-controlled production process to ensure each ASTM B365 Tantalum Alloy Wire meets international standards.

Production steps:

- Raw Material Selection: Certified tantalum ingots and alloys.

- Melting: Electron beam or vacuum arc melting to ensure purity and homogeneity.

- Forging & Rolling: Hot and cold working to achieve the required wire diameter and density.

- Drawing Process: Multi-stage drawing with annealing for uniform grain structure.

- Surface Treatment: Polishing and cleaning to remove oxides and impurities.

- Final Inspection: Dimensional, chemical, and mechanical tests before delivery.

Each stage is monitored under ISO 9001:2015 quality control, ensuring stable performance and dimensional accuracy.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is at the core of our operations. Every ASTM B365 Tantalum Alloy Wire undergoes a full inspection process, including:

- Chemical Composition Analysis (ICP-OES or XRF)

- Mechanical Testing (tensile strength, elongation)

- Ultrasonic & Visual Examination

- Surface Roughness & Diameter Tolerance Measurement

- Density & Purity Verification

All test results are traceable and accompanied by inspection certificates in compliance with ASTM, AMS, and GB standards.

R&D and Customization

With over 30 years of rare metal expertise, our R&D team focuses on developing new tantalum alloy formulations and precision wire products.

- Customized alloy grades and surface finishes.

- Special diameters for microelectronic or medical applications.

- Prototype and small-batch production for testing purposes.

- Material selection support for high-temperature or corrosive environments.

Continuous research allows us to improve the mechanical properties and oxidation resistance of our ASTM B365 Tantalum Alloy Wire for next-generation industries.

Packaging & Global Logistics

To ensure safe delivery, every wire is packaged under strict export standards:

- Inner Packaging: Vacuum-sealed or anti-rust film wrapping.

- Outer Packaging: Foam protection and export-grade wooden cases.

- Marking: Each spool labeled with material grade, batch number, and size.

- Shipping: Fast and secure transport via air, sea, or courier to 50+ global markets.

All packaging complies with international export requirements to guarantee corrosion-free arrival.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides flexible OEM and ODM solutions, including:

- Custom wire dimensions and tolerances.

- Private labeling and technical data sheets.

- Support for R&D projects and special alloy compositions.

- Rapid sample manufacturing and low-volume orders.

We ensure each ASTM B365 Tantalum Alloy Wire order meets specific client application needs with fast turnaround and professional service.

Inspection Process

Every production batch follows a systematic inspection flow:

- Incoming Raw Material Verification

- Process Control & Sampling Tests

- Final Mechanical & Chemical Testing

- Visual and Dimensional Check

- Packing and Certification Review

This rigorous procedure ensures product consistency and compliance with ASTM B365 requirements.

Why Choose Us

- Over 30 Years of Expertise: Deep industry experience in tantalum and rare metal production.

- Comprehensive Manufacturing Capability: Full control from melting to precision drawing.

- Certified Quality: ISO 9001:2015 management system ensures traceable quality assurance.

- Global Export Experience: Trusted by clients in 50+ countries worldwide.

- Fast Delivery & Reliable Support: Standard orders shipped within 7 days.

Shaanxi Chuanghui Daye is your dependable partner for high-performance ASTM B365 Tantalum Alloy Wire solutions.

|

|

|

|

|

|

FAQs

Q1: What is the standard purity of your tantalum alloy wire?

A1: The standard purity is 99.95%, with ultra-high purity options available upon request.

Q2: What wire diameters can you supply?

A2: Diameters range from 0.1 mm to 5.0 mm, and custom sizes are available for specific applications.

Q3: Do you accept small or prototype orders?

A3: Yes, we provide small-batch and prototype manufacturing for research and pilot projects.

Q4: What is the usual delivery time?

A4: Standard specifications are typically shipped within 7 days; customized products may vary.

Q5: Which industries use your tantalum alloy wire?

A5: It is widely used in electronics, aerospace, medical, and chemical processing sectors for components requiring excellent corrosion and heat resistance.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email