- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

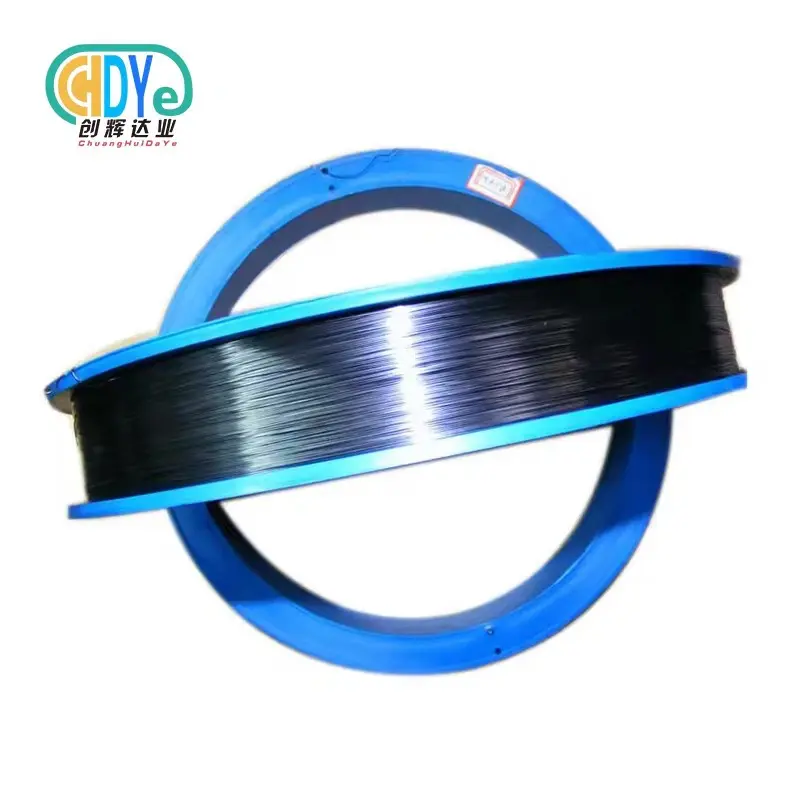

Pure Tungsten Wire

Surface:Black, chemical cleaned and polished.

Feature:High-density, high temperature oxidation resistance, long service life, resistance to corrosion

Product Introduction

The Pure Tungsten Wire from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is engineered for high-temperature, high-stress, and precision applications. Manufactured from ultra-high purity tungsten, this wire exhibits excellent tensile strength, remarkable thermal stability, and outstanding resistance to oxidation and corrosion. It is widely used in electronic, metallurgical, and vacuum applications where reliability and performance are critical.

Pure Tungsten wire mainly used to make filaments of incandescent lamp, fluorescent lamps, and halogen lamps, electrode of HID lamps,heating components, vacuum metallizing coils, and TIG welding electrodes. we try our best to explore new products with high quality and has formed the capacity to manufacture series tungsten products, including all kinds of black tungsten wires and cleaned tungsten wires, tungsten filament, tungsten stranded wires,conductor wire, tungsten heater, doped tungsten wire, non-sag tungsten wire,tungsten rhenium wires etc.

Properties and Characteristics:

1. High temperature property: according to the specific applications, high temperature property requirements;

2. Diameter consistency. weight deviation of two consecutive 200mm-wire pieces is less than 0. 5% of nominal;

3. Straightness:Regular tungsten wire in accordance with customers' requirements Straightened tungsten wire. for the tungsten wire thinner than 100um. vertical height of 500mm freely,suspended wire should not be less than 450mm:for the tungsten wire at or thicker than 10oum, the maximum arc height between two points with distance of 100mm is 10mm;

4. Surface conditions: smooth surface, free of splits, burrs, cracks, dents, dots. grease contamination.

|

Material: |

Pure tunsgten wire |

|

Purity: |

99.95%Min. |

|

Melting Point: |

3410℃ |

|

Surface: |

Black, chemical cleaned and polished. |

|

Density: |

19.2g/cm3 |

|

Diameter: |

0.01-2.00mm |

|

Tensile Strength: |

2770 N/mm2 |

|

MOQ |

1KG |

|

Feature |

High-density, high temperature oxidation resistance, long service life, resistance to corrosion. |

Specification:

|

Diameter, mm |

Diameter telorance, % |

Weight ( 200mm ), mg |

Length min, m |

|

0.012−0.06 |

- |

>0.44−10.91 |

700 |

|

0.06−0.1 |

- |

>10.91−30.30 |

400 |

|

0.1−0.15 |

-- |

>30.30−68.18 |

250 |

|

0.15−0.2 |

- |

>68.18−121.20 |

150 |

|

0.2−0.35 |

- |

>121.20−371.19 |

100 |

|

0.35−0.7 |

±1.5−±2.5 |

- |

same as 150g |

|

0.7−1.8 ± |

±1.0−±2.0 |

- |

same as 200g |

Chemical Composition:

|

Chemical content (%) |

As |

Si |

Sb |

Mg |

Pb |

Sn |

|

<0.0001 |

<0.001 |

<0.0001 |

<0.0001 |

<0.0001 |

<0.0001 |

|

|

Fe |

Ni |

Bi |

Al |

Ca |

Mo |

|

|

0.0013 |

0.0002 |

<0.0001 |

0.0002 |

<0.001 |

0.017 |

|

|

P |

N |

O |

C |

W |

||

|

<0.001 |

0.0020 |

0.0046 |

0.0010 |

>99.95 |

Advantages:

• 3180℃ High melting point;

• Excellent high temperature ductility;

• Over a wide temperature range with high resistivity;

• Strong resistance to chemical corrosion;

• Good oxidation resistance at high temperature;

• Good thermal shock resistance;

• Low vapor pressure.

Packaging and shipping Details:

1. plastic foam packing inside

2. Plywood box packing outside

3.We ship worldwide by EMS ,DHL ,UPS ,FedEx ,TNT and so on;

Application Advantages

The Pure Tungsten Wire is designed for industries and applications requiring extreme performance:

- Electronics and Semiconductors: Used in vacuum tubes, electron emitters, and thin-film deposition.

- Aerospace and Defense: Suitable for high-temperature elements, precision components, and thermal shielding.

- Metallurgy: Applied in high-temperature furnaces, electrodes, and molten metal handling.

- Medical Equipment: Used in X-ray tubes and specialized diagnostic devices.

- Scientific Research: Ideal for laboratories and high-temperature experimental setups.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Pure Tungsten Wire involves advanced metallurgical techniques:

- Raw Material Selection: High-purity tungsten powders are carefully chosen to ensure optimal mechanical and thermal properties.

- Powder Metallurgy: Tungsten powders are compacted and sintered at ultra-high temperatures to achieve density and uniformity.

- Drawing and Extrusion: The sintered billets are drawn into wire through a series of dies, ensuring precise diameter and smoothness.

- Annealing: Heat treatment processes relieve stress and improve ductility.

- Surface Finishing: Polishing and coating are applied as needed to meet application-specific requirements.

- Final Inspection: Each wire undergoes strict quality control before packaging.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye ensures the highest quality for every Pure Tungsten Wire:

- Chemical Composition Testing: Verifies tungsten purity and confirms the absence of contaminants.

- Dimensional Accuracy: Checks wire diameter and tolerance specifications.

- Mechanical Testing: Confirms tensile strength, elongation, and thermal resistance.

- Surface Inspection: Ensures smoothness, absence of cracks, and uniformity.

- Traceability: Batch numbers and specifications are labeled for full quality tracking.

These rigorous inspections ensure consistent product performance in critical applications.

R&D and Customization

- Custom Diameters and Lengths: Tailored to specific industry requirements.

- Prototype & Small-Batch Production: Supports specialized applications and R&D projects.

- Material Consultation: Experts provide guidance on alloying, thermal resistance, and mechanical performance.

- Design Optimization: Enhancements for ductility, conductivity, and long-term durability.

Customers benefit from highly customized solutions designed to meet exact operational needs.

Packaging & Global Logistics

- Wrapped in vacuum or anti-rust film to prevent oxidation.

- Foam padding and reinforced wooden crates protect the wire during transit.

- Clear labeling with batch numbers and specifications for easy identification.

- Reliable air, sea, and land transportation to over 50 countries including the USA, Germany, France, South Korea, and Singapore.

This packaging guarantees the integrity of the wire upon arrival.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye provides OEM and customization services for Pure Tungsten Wire:

- Custom diameters, lengths, and surface treatments.

- Small-batch and prototype production for research and industrial applications.

- Technical support for material selection and performance optimization.

- Comprehensive after-sales support to ensure consistent product satisfaction.

These services allow clients to obtain wires optimized for demanding operational requirements.

Inspection Process

Each Pure Tungsten Wire undergoes a meticulous inspection workflow:

- Raw Material Verification: Confirms high-purity tungsten and correct specifications.

- Dimensional Control: Checks diameter and tolerance for precision applications.

- Mechanical Testing: Verifies tensile strength, elongation, and thermal properties.

- Surface Examination: Detects defects, cracks, or surface irregularities.

- Final Approval & Packaging: Ensures readiness for shipment and immediate use.

This thorough inspection guarantees reliability and durability for all applications.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a trusted global supplier of high-purity tungsten and rare metal products:

- Over 30 years of expertise in tungsten and refractory metals.

- ISO 9001:2015 certified quality management system.

- Advanced facilities including electron beam furnaces, rolling, and precision machining.

- Products exported to more than 50 countries worldwide.

- Comprehensive OEM and technical support services.

- Commitment to premium quality, on-time delivery, and competitive pricing.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of the wire?

A1: The Pure Tungsten Wire is made from ultra-high purity tungsten, ensuring excellent mechanical and thermal performance.

Q2: Can the wire be customized?

A2: Yes, we provide custom diameters, lengths, and surface treatments based on client requirements.

Q3: Which industries typically use this wire?

A3: Electronics, aerospace, defense, metallurgy, scientific research, and medical equipment.

Q4: How is the wire packaged for international shipping?

A4: Wrapped in vacuum or anti-rust film, protected with foam, and shipped in reinforced wooden crates.

Q5: Do you provide technical support for selecting the appropriate wire?

A5: Yes, our experts offer guidance on material choice, thermal performance, and mechanical optimization.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email