- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

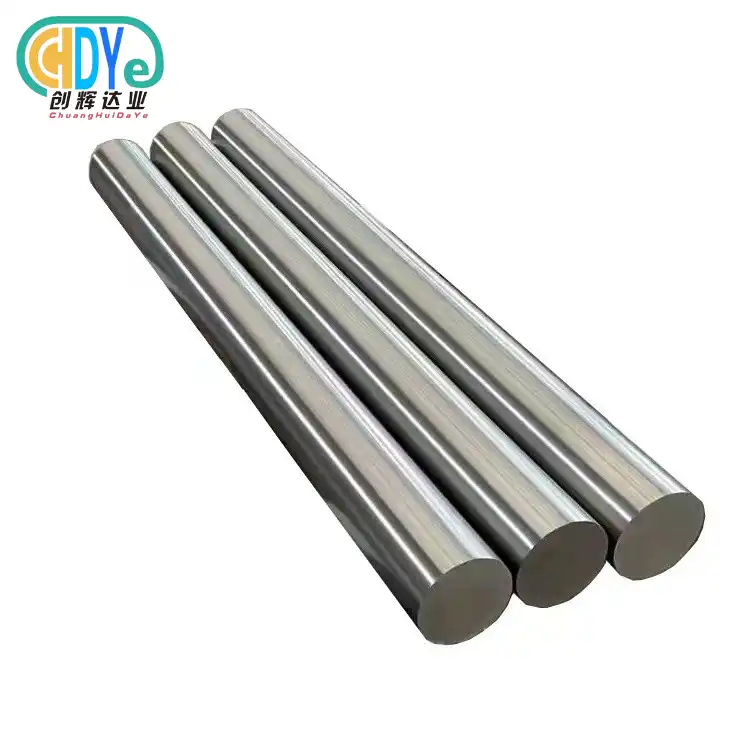

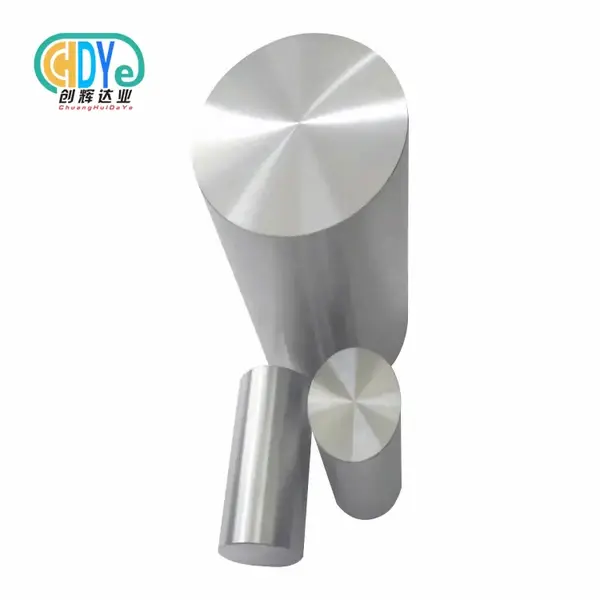

Tantalum Round Bar

2.Diameter: 2-100mm

3.Standard: ASTM B 365

4.Delivery time: stock size will arrange within 1-3 days, normal production time about 15 working day.

Product Introduction

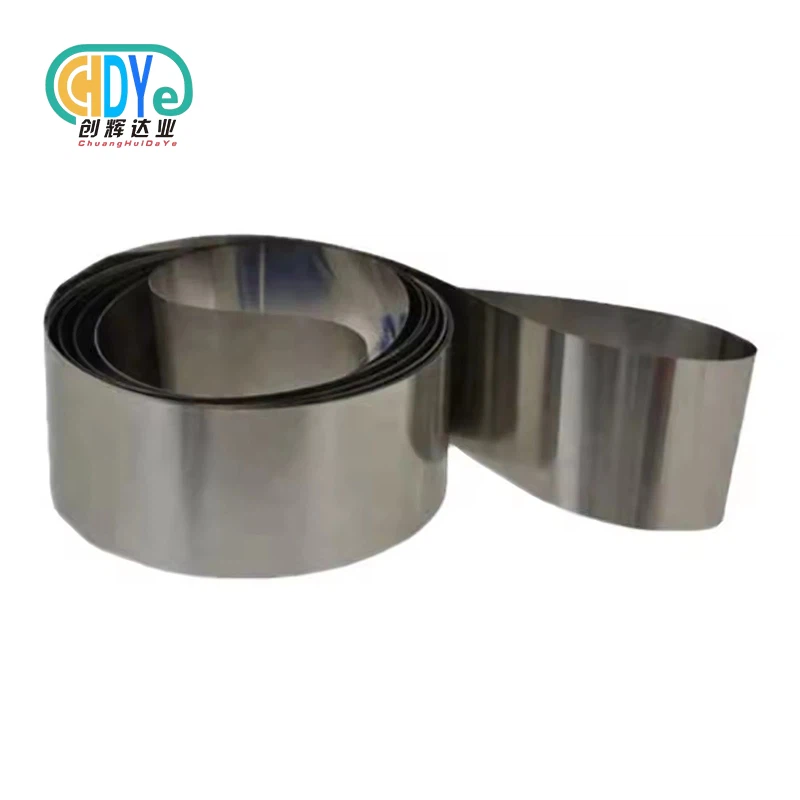

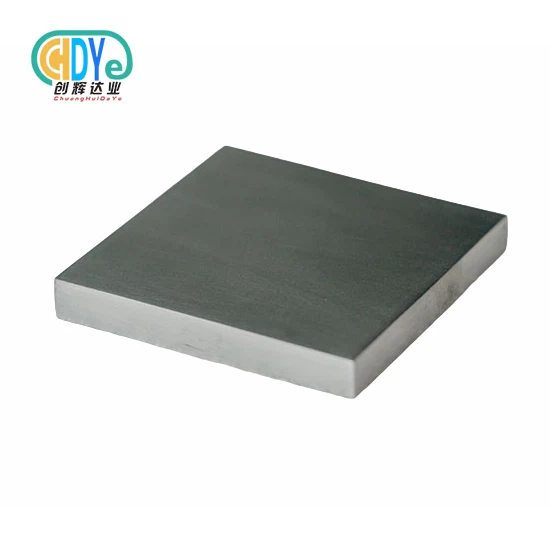

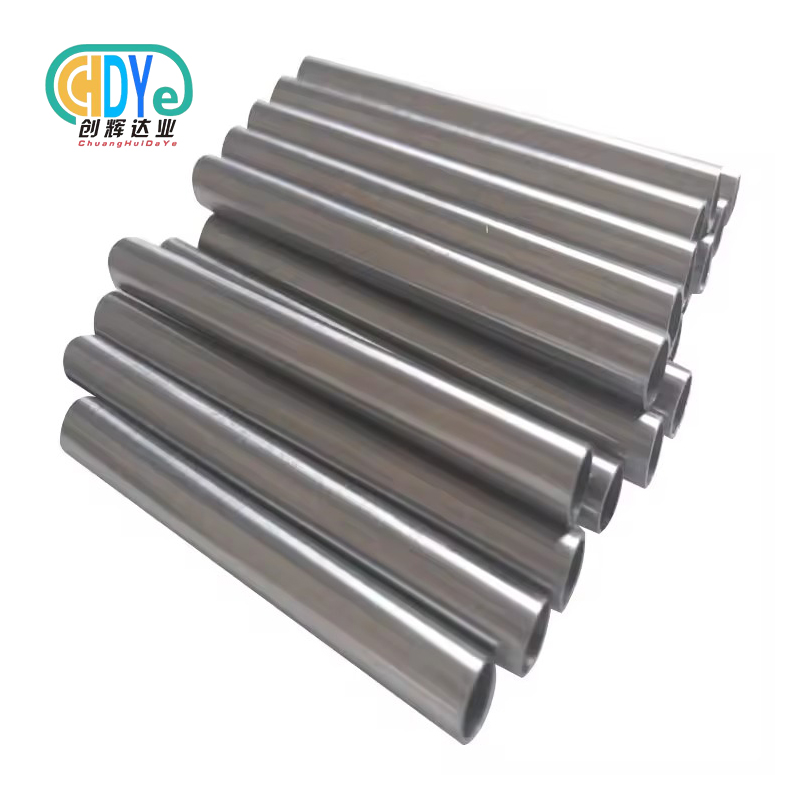

The Tantalum Round Bar is a premium refractory metal product known for its exceptional corrosion resistance, high melting point (over 2996°C), and excellent formability. Manufactured from high-purity tantalum ingots through precision forging, rolling, and annealing processes, it maintains outstanding mechanical stability even under extreme conditions. With its superior resistance to acids and oxidation, the Tantalum Round Bar is widely used in chemical equipment, aerospace structures, electronic components, and medical instruments. Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces Tantalum Round Bars in full accordance with ASTM B365 and other international standards, offering consistent quality, precise dimensions, and customizable specifications to meet the diverse needs of global industries.

Chdymetal can offer tantalum round bar with various purities and sizes.

Specification

Grade: R05200 / R05400

Diameter: 2-100mm

Standard: ASTM B 365

Delivery time: stock size will arrange within 1-3 days, normal production time about 15 working day.

|

Product name |

Pure Tantalum bar |

|

Application |

Electronic Light Source Part;Implantation Parts.etc |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ2.0-100mm*L,customized |

|

Chemical Composition |

Pure Tantalum Rods/Bars |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

Related Products

Application Advantages

One of the main uses of tantalum is in the production of electronic components. An oxide layer which forms on the surface of tantalum can act as an insulating (dielectric) layer. Because tantalum can be used to coat other metals with a very thin layer, a high capacitance can be achieved in a small volume. This makes tantalum capacitors attractive for portable electronics such as mobile phones.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of the Tantalum Round Bar follows a strict sequence to guarantee precision and consistency:

- Raw Material Selection – Only high-purity tantalum ingots are chosen.

- Vacuum Melting – Electron beam or powder metallurgy melting ensures purity and homogeneity.

- Forging and Rolling – Hot forging and rotary rolling improve strength and refine the grain structure.

- Annealing – Controlled annealing relieves internal stress and enhances ductility.

- Precision Machining – Final turning, straightening, and polishing achieve exact dimensions and smooth surfaces.

- Inspection and Packaging – 100% quality inspection before export to ensure flawless performance.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Each Tantalum Round Bar undergoes comprehensive inspection procedures throughout production. This includes chemical composition analysis (ICP-OES), ultrasonic flaw detection, tensile testing, hardness measurement, and dimensional verification. Our ISO 9001:2015 certified system ensures traceability, consistency, and compliance with ASTM B365 and other international standards.

R&D and Customization

Shaanxi Chuanghui Daye’s experienced R&D team continuously develops advanced solutions for high-performance tantalum materials. We provide customized Tantalum Round Bar options based on specific customer drawings, grades, and applications. Our engineers assist clients in material selection, performance optimization, and prototype development to meet specialized industrial requirements.

Packaging & Global Logistics

Each Tantalum Round Bar is packed using export-standard materials, including vacuum sealing or anti-rust wrapping, foam protection, and sturdy wooden cases. All packaging is clearly labeled with specifications and batch numbers. Global shipping via air, sea, or express ensures timely delivery to over 50 countries, including the USA, Germany, Japan, and South Korea.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer comprehensive OEM and ODM services, supporting custom dimensions, mechanical properties, and surface finishes. Our professional technical team provides design consultation, trial manufacturing, and small-batch testing to help customers achieve cost-effective and performance-oriented solutions.

Inspection Process

-

Incoming raw material verification

-

Chemical and mechanical property testing

-

Dimensional measurement during processing

-

Surface finish inspection after polishing

-

Final inspection and packaging quality check

Why Choose Us

-

Over 30 years of rare metal production experience

-

ISO 9001:2015 certified manufacturing system

-

100% quality inspection and traceability

-

Strong R&D and technical support team

-

Fast 7-day delivery for standard sizes

-

Trusted by customers in more than 50 global markets

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your tantalum bars?

A1: Our tantalum bars are typically 99.95% pure, with higher purities available upon request.

Q2: What sizes are available?

A2: Diameters range from 3 mm to 100 mm, with custom sizes and tolerances available.

Q3: Can I order small quantities or prototypes?

A3: Yes, we provide sample and small-batch production for research and testing needs.

Q4: How do you ensure quality consistency?

A4: Every batch is fully inspected using advanced analytical and mechanical testing equipment under ISO-certified processes.

Q5: What are the typical applications?

A5: Common uses include chemical equipment, aerospace components, medical devices, and high-temperature furnace parts.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email