- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

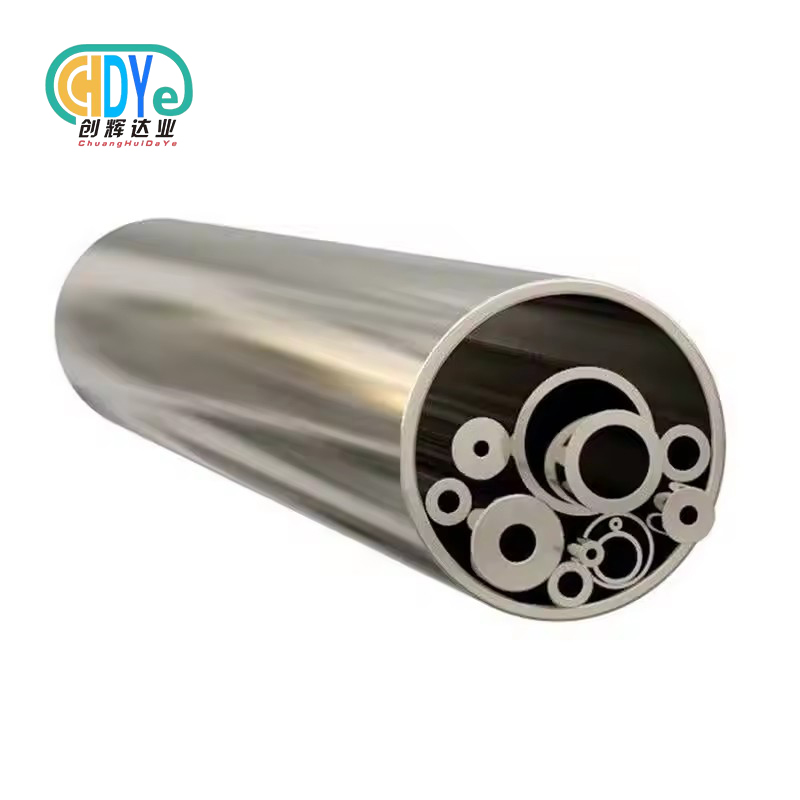

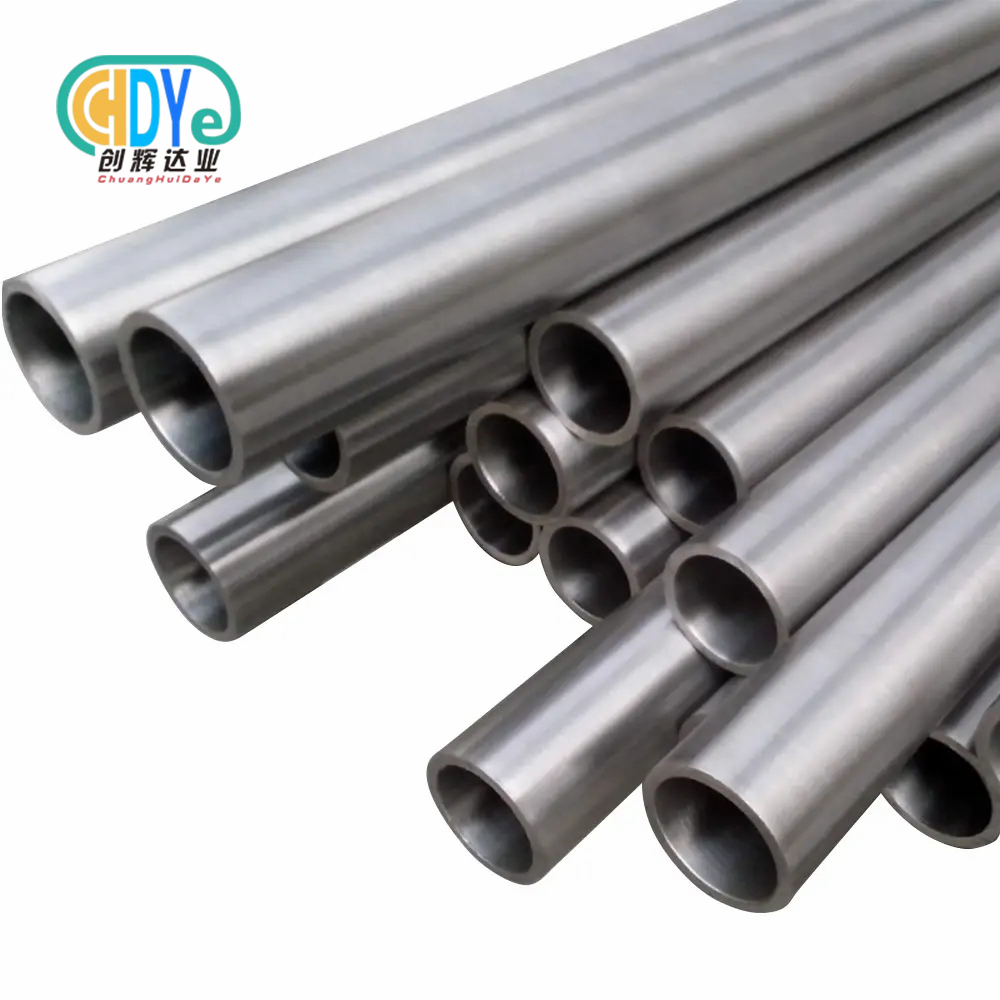

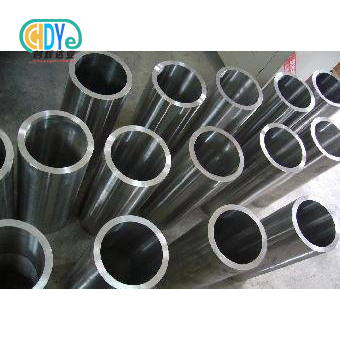

Titanium Alloy Tube

2.Standard: ASTM B338 ASTM B337 B861 B862

3.Dimension:OD10-300xWT0.5-10x L100-18000 MM

Product Introduction

Titanium alloy tube is a high-performance tubular product made from titanium-based alloys that combine excellent mechanical strength, low density, and superior corrosion resistance. These tubes are engineered for demanding applications where high strength-to-weight ratio, thermal stability, and resistance to aggressive environments are essential.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. produces titanium alloy tubes using precision melting, extrusion, and cold-working technologies to achieve exceptional structural integrity. Our titanium alloy tubes are widely used in aerospace systems, power generation, chemical engineering, and high-performance automotive industries.

Chdymetal is a global metal supplier of titanium alloy tube, we can provide various grade and type, As its unique combination of high strength, light weight, corrosion resistance, bio-compatibility, and higher temperature performance, Titanium alloy tube is widely used in aerospace, medical, industrial, and oil and gas industries.

1.Item Name: titanium alloy tube

2.Grade :Gr1 Gr2 Gr7 Gr9 Gr12

3.Standard: ASTM B338 ASTM B337 B861 B862

4.Dimension:OD10-300xWT0.5-10x L100-18000 MM

5.Condition: annealed

6.Type: seamless and welded

7. titanium alloy tube Application

1)heat exchanger and Condenser; U Type coil pipe ;

2)Petroleum pipeline ; Sea farming;

3)Evaporator; Fluid Transportation Piping etc.

8. Chemical Composition of titanium alloy Tubes

|

Element |

Chemical Composition % |

||||||||

|

Grade 1 |

Grade 2 |

Grade 3 |

Grade 5 |

Grade 7 |

Grade 9 |

Grade 11 |

Grade 12 |

Grade 23 |

|

|

Nitrogen, max |

0.03 |

0.03 |

0.05 |

0.05 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

|

Carbon, max |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

|

Hydrogen, max |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.015 |

0.0125 |

|

Iron, max |

0.2 |

0.3 |

0.3 |

0.4 |

0.3 |

0.25 |

0.2 |

0.3 |

0.25 |

|

Oxygen, max |

0.18 |

0.25 |

0.35 |

0.2 |

0.25 |

0.15 |

0.18 |

0.25 |

0.13 |

|

Aluminum |

… |

… |

… |

5.5-6.75 |

… |

2.5-3.5 |

… |

… |

5.5-6.5 |

|

Vanadium |

… |

… |

… |

3.5-4.5 |

… |

2.0-3.0 |

… |

… |

3.5-4.5 |

|

Tin |

… |

… |

… |

… |

… |

… |

… |

… |

… |

|

Ruthenium |

… |

… |

… |

… |

… |

… |

… |

… |

… |

|

Palladium |

… |

… |

… |

… |

0.12-0.25 |

… |

0.12-0.25 |

… |

… |

|

Molybdenum |

… |

… |

… |

… |

… |

… |

… |

0.2-0.4 |

… |

|

Chromium |

… |

… |

… |

… |

… |

… |

… |

… |

… |

|

Nickel |

… |

… |

… |

… |

… |

… |

… |

0.6-0.9 |

… |

|

Ziconium |

… |

… |

… |

… |

… |

… |

… |

… |

… |

|

Silicon |

… |

… |

… |

… |

… |

… |

… |

… |

… |

|

Residuals, max each |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

|

Residuals, max total |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

|

Titanium |

balance |

balance |

balance |

balance |

balance |

balance |

balance |

balance |

balance |

Titanium alloy tube Applications

Our titanium seamless tubes are used in various applications, including:

- Aerospace: Titanium is used in aircraft components and structures due to its high strength, low weight, and excellent corrosion resistance.

- Chemical processing: Titanium is used in pipes, tanks, and valves in chemical processing plants due to its excellent corrosion resistance.

- Biomedical: Titanium is biocompatible, making it ideal for medical implants and devices such as orthopedic implants, dental implants, and surgical tools.

- Marine: Titanium is used in shipbuilding and offshore structures due to its excellent corrosion resistance in saltwater environments.

Titanium alloy tube stock

|

|

|

Product Features & Advantages

- Outstanding Strength-to-Weight Ratio: Titanium alloys such as Gr5 and Gr23 deliver excellent tensile and yield strength with only half the weight of steel.

- Excellent Corrosion Resistance: Resistant to oxidizing, chloride, and acidic environments, ideal for chemical and marine applications.

- Superior High-Temperature Performance: Maintains stability and mechanical strength under thermal cycling up to 600°C.

- Precision Workability: Suitable for precision machining, welding, and bending without loss of integrity.

- Long Service Life: Excellent fatigue resistance ensures long-term reliability even under dynamic loads.

- Customizable Alloy Options: Tailored alloy composition for aerospace, power, or medical applications.

Applications

Titanium alloy tubes are engineered to perform in the most demanding industries, offering a combination of light weight, strength, and corrosion resistance.

- Aerospace & Defense: Hydraulic systems, landing gear components, and heat exchangers.

- Automotive Engineering: High-performance exhaust systems and lightweight frame structures.

- Chemical Processing: Tubing for reactors, condensers, and pipelines carrying corrosive media.

- Power Generation: Tubes for condensers and coolers in nuclear, thermal, and geothermal plants.

- Medical Equipment: Biocompatible alloy tubes used in surgical instruments and orthopedic implants.

- Sports Equipment: Lightweight and durable components for bicycles and racing applications.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Our titanium alloy tube manufacturing process combines advanced equipment and strict metallurgical control to ensure optimal quality and consistency.

- Vacuum Melting & Forging: Ensures uniform alloy composition and low impurity levels.

- Precision Extrusion: Achieves fine-grain microstructure and high density.

- Cold Drawing & Heat Treatment: Enhances dimensional accuracy and mechanical strength.

- Ultrasonic Cleaning: Removes contaminants for a smooth, oxidation-free surface.

- Automatic Inspection: Full non-destructive testing for each tube to guarantee safety and reliability.

Shaanxi Chuanghui Daye operates a full production chain from billet melting to final finishing, enabling stable supply and customized production.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is integrated into every step of production. Our titanium alloy tubes meet international standards and undergo rigorous testing before delivery.

Main Inspection Procedures:

- Raw material chemical analysis using spectrometers

- Mechanical property tests (tensile, yield, elongation, hardness)

- Non-destructive testing (eddy current, ultrasonic, hydrostatic)

- Surface roughness and straightness measurement

- Dimensional accuracy verification

- Final inspection and marking according to customer specification

All data are recorded for full traceability under ISO 9001:2015 quality management certification.

OEM & Customization Services

We support customized titanium alloy tube production for a wide range of industrial requirements:

- Alloy selection based on specific mechanical or thermal requirements

- Customized diameter, wall thickness, and length

- Tubes with threaded ends, flanged joints, or welded connections

- Precision machining and surface treatment services

- Private labeling and export packaging design

- Prototype development and mass production for OEM clients

Our engineering team works closely with buyers to optimize design, material performance, and delivery efficiency.

Packaging & Global Logistics

Each titanium alloy tube is packaged to ensure surface protection and safe transport worldwide.

- Inner Packaging: Anti-rust paper or plastic film wrapping

- Outer Packaging: Wooden boxes, steel frames, or bundled with nylon straps

- Marking: Material grade, heat number, dimensions, and manufacturer name

- Delivery Options: Air freight, sea shipment, or express service with full documentation

Special protective materials are available for marine or humid storage conditions to prevent oxidation during transit.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Inspection Process

1. Appearance and dimension inspection to ensure every titanium tube meets tolerances,no cracks, pits or other defects on the surface.

2. 100% Straightness inspection.

3. 100% Hydro Testing.

4. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

5. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Why Choose Us

- Over 30 years of experience in titanium and alloy tube manufacturing

- Full ISO 9001:2015 certified quality control system

- Advanced production and inspection facilities ensuring stable output

- Custom alloy composition and dimension design for global buyers

- Fast delivery and competitive wholesale pricing

- Strong export capability to more than 60 countries

- Dedicated technical engineers supporting R&D and after-sales service

We are a trusted partner for OEM, industrial projects, and global distributors in the titanium alloy tube industry.

|

|

|

|

|

|

FAQs

Q1: What’s the difference between pure titanium tube and titanium alloy tube?

A1: Titanium alloy tube offers higher strength, better temperature resistance, and fatigue performance compared to pure titanium tubes.

Q2: Can your titanium alloy tubes be used in high-pressure systems?

A2: Yes, our tubes are tested and certified for high-pressure operation, meeting ASTM and ASME standards.

Q3: Which titanium alloy grade is best for aerospace applications?

A3: Ti-6Al-4V (Gr5) and Ti-6Al-4V ELI (Gr23) are most commonly used due to their high strength and excellent toughness.

Q4: Do you provide custom surface finishes?

A4: Yes, finishes like polished, sandblasted, or bright-annealed are available based on project requirements.

Q5: How do you ensure tube straightness and uniform wall thickness?

A5: We use multi-step cold drawing and digital measurement to maintain precision and tight dimensional tolerance.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email