- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

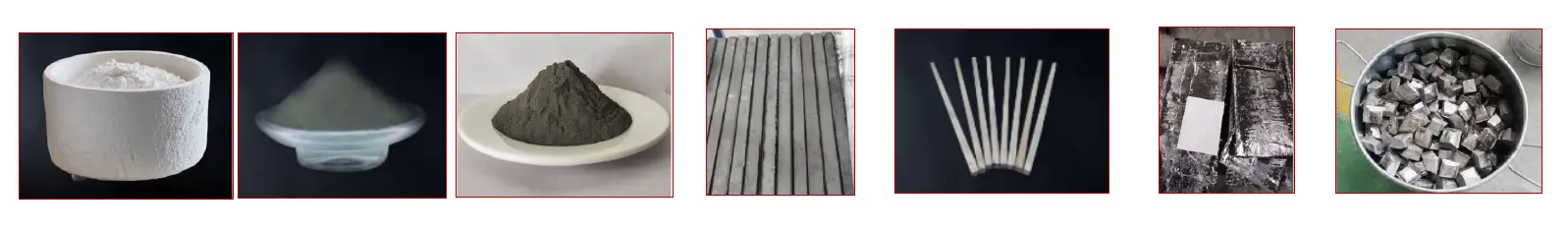

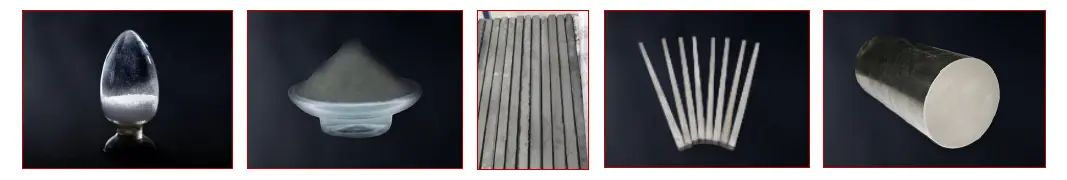

tantalum block

2.Specifications: (17 × 17) ± 3 × 450 ± 50mm or as your request

3.Packing : wooden box 50kg/ box or customized

4.Application: Used as special alloy and high temperature alloy additive

Looking for superior tantalum block solutions for your industrial applications? You've found the right partner. Our premium tantalum blocks offer exceptional purity of 99.9% and outstanding performance characteristics. With over 30 years of expertise in rare metal manufacturing, we deliver reliable, high-quality products that meet your exact specifications. Whether you need standard dimensions or custom configurations, our tantalum block products provide the durability and precision your projects demand.

Product Introduction

Our tantalum blocks represent the pinnacle of rare metal engineering. Manufactured to YS/T1005-2014 standards, these blocks deliver consistent quality and performance. Each block undergoes rigorous purification in horizontal electron beam furnaces, ensuring optimal material properties for demanding applications.

Key Features and Benefits

- Ultra-High Purity: 99.9% purity ensures superior performance

- Exceptional Corrosion Resistance: Withstands harsh chemical environments

- Extreme Temperature Stability: Operates reliably at temperatures up to 3017°C

- Excellent Machinability: Superior ductility and plasticity for easy processing

- Low Oxygen Content: ≤150 ppm oxygen enhances thermal stability

- Consistent Quality: Every batch meets strict international standards

Technical Specifications

|

Nb |

O |

C |

N |

Fe |

Ni |

Cr |

Mn |

|

|

Standard value |

0.02 |

0.25 |

0.015 |

0.02 |

0.01 |

0.01 |

0.005 |

0.003 |

|

|

Si |

Ti |

Zr |

W |

Al |

Mo |

Cu |

- |

|

Standard value |

0.01 |

0.003 |

0.003 |

0.005 |

0.003 |

0.003 |

0.003 |

- |

Available Grades and Materials

We primarily offer Ta-1 grade, the most widely used industrial standard. This grade provides optimal balance between purity, mechanical properties, and cost-effectiveness. Custom grades are available upon request to meet your specific application requirements.

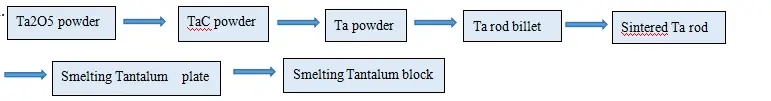

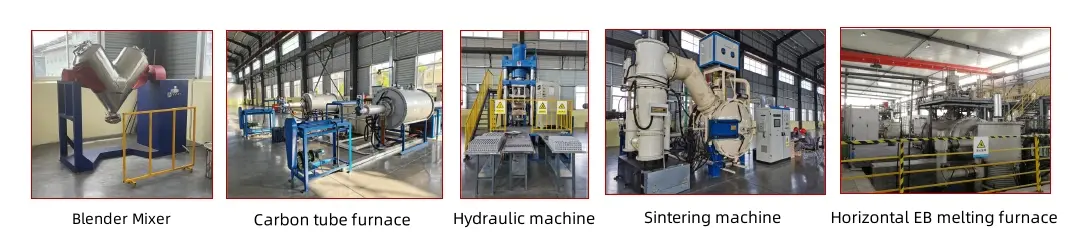

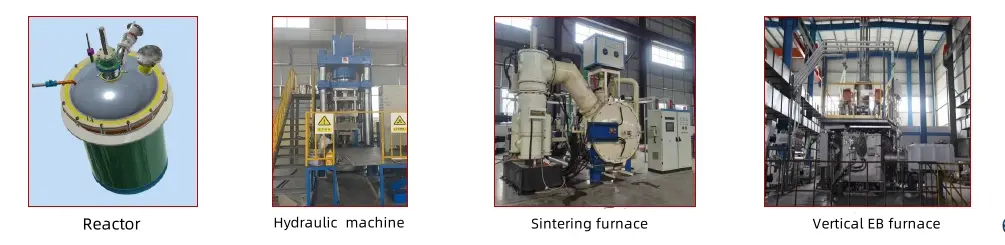

Manufacturing Process

Our advanced production process ensures exceptional quality:

- Raw Material Selection: Premium tantalum ore processing

- Electron Beam Melting: Horizontal furnace purification

- Ingot Formation: Controlled cooling and solidification

- Mechanical Processing: Precision cutting and shaping

- Quality Testing: Comprehensive inspection and certification

This refined process ensures superior quality and eliminates impurities that could affect your final products.

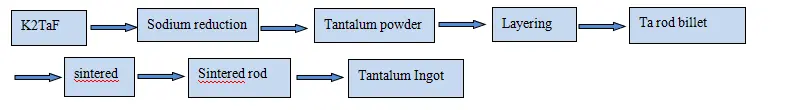

Two processes for producing tantalum blocks

Carbon reduction tantalum bar process flow C+Ta2O5( Nb2O5)→Ta(Nb)+CO ↑

Sodium reduction tantalum bar process flow (K2TaF7+5Na=Ta+5NaF+2KF )

Applications and Industries

Your projects benefit from versatile applications:

Aerospace Industry: Superalloy additives and high-temperature components

Chemical Processing: Corrosion-resistant equipment and vessels

Electronics Manufacturing: Capacitor production and semiconductor applications

Medical Devices: Biocompatible implants and surgical instruments

Research Facilities: Laboratory equipment and specialized tooling

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Features in Detail

Our products excel in demanding environments. The high melting point of 3017°C makes these blocks ideal for extreme temperature applications. Superior corrosion resistance protects against aggressive chemicals, while excellent ductility ensures easy processing and forming.

When you choose our materials, you get consistent thermal conductivity and stable resistivity. These properties make our tantalum block products perfect for precision applications where reliability matters most.

Quality Assurance and Testing

We maintain strict quality control throughout production. Each batch undergoes comprehensive testing including:

- Chemical composition analysis

- Mechanical property verification

- Dimensional accuracy inspection

- Surface quality assessment

- Purity confirmation testing

|

|

|

OEM & Customization Services

Need specific dimensions or properties? We offer comprehensive customization services. Our experienced team works with you to develop solutions that match your exact requirements. From custom sizes to specialized processing, we adapt our manufacturing to meet your needs.

Packaging and Shipping

Your orders arrive safely with our professional packaging:

- Standard Packaging: Wooden boxes, 50kg capacity

- Protection: Moisture-resistant wrapping and shock absorption

- Global Shipping: Reliable delivery to over 50 countries

- Documentation: Complete certificates and material traceability

Why Choose Us

Located in China's "Titanium Capital," we bring three decades of rare metal expertise to your projects. Our founder's extensive industry experience ensures you receive products that exceed expectations. We focus on competitive pricing, on-time delivery, and customer-focused service.

Our commitment to continuous improvement means you benefit from the latest manufacturing techniques and quality standards. When you partner with us, you choose reliability, honesty, and exceptional tantalum block quality.

|

|

|

|

|

|

FAQs

Q: What's your minimum order quantity?

A: We accommodate both small and large orders based on your specific needs.

Q: Can you provide custom dimensions?

A: Yes, we offer comprehensive customization services for dimensions and specifications.

Q: What certifications do your products have?

A: All products meet YS/T1005-2014 standards with complete material certificates.

Q: How do you ensure consistent quality?

A: We implement rigorous testing protocols and maintain strict quality control throughout production.

Contact Us

Ready to discuss your requirements? Our experienced team is here to help. Whether you need technical specifications, custom solutions, or pricing information, we're committed to providing exceptional service.

Email: info@chdymetal.com

Mob./what's app.: 86-18049386902

Contact us today to discover how our premium tantalum block products can enhance your projects. We look forward to becoming your trusted rare metal partner.

Learn about our latest products and discounts through SMS or email