- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

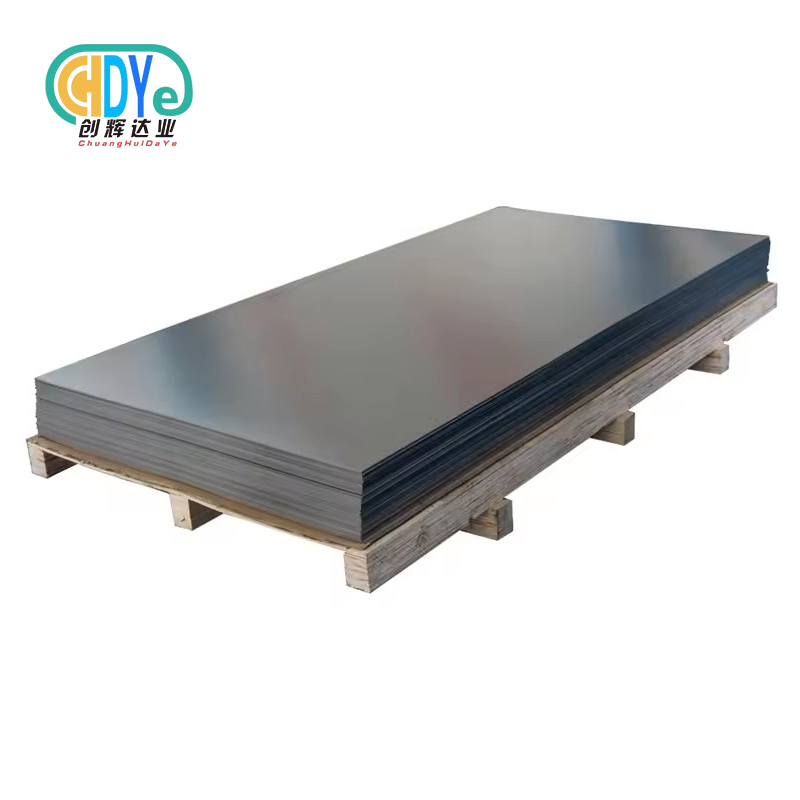

ASTM B708 Tantalum Alloy Plate

2.Size:Thickness 0.5-20mm*width50-1200*Length30-2500mm

Product Introduction

Tantalum metal is stable in air at room temperature, when heated above 500 ° C, oxidation is accelerated to produce Ta205. Tantalum has a series of excellent properties such as high melting point, low steam pressure, good cold working performance, high chemical stability, strong resistance to liquid metal corrosion, and large dielectric constant of surface oxide film, and has important applications in high-tech fields such as electronics, metallurgy, steel, chemical industry, cemented carbide, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research.

|

Product Name |

ASTM B708 Tantalum Alloy Plate |

|

Purity |

99.95% min |

|

Standard |

ASTM B708 |

|

Size |

Thickness 0.5-20mm*width50-1200*Length30-2500mm or customized |

|

UNS Grade |

R05200, R05240, R0525, R05255 |

|

Customized products |

According to drawing, Special requirements to be agreed upon by the supplier and buyer. |

|

Packing term |

Foam packing inside, wooden box outside |

|

Delivery time |

Stock size within 1-5 days normal production time about 15 days |

|

Payment term |

30%TT in advance,70% balance before shipment OR LC |

|

Express |

DHL, FedEx, TNT by air,by sea |

Our advantages

1. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

2. Chdymetal can cut to precise dimensions with very tight tolerances. Rather than ordering big plates and cutting the material yourself, let us do the cutting for you and reduce your risk and scrap.

3. You can get stock alternatives, usually stock size we can arrange 1-3 days quick delivery to save your time.

4. Fast response time

*Within 1 hour on working days

*Within 24 hours on non-working days

Application Advantages

ASTM B708 Tantalum Alloy Plate is a high-performance material engineered for extreme chemical and thermal environments. With its superior corrosion resistance, ductility, and high melting point (over 3000°C), tantalum plate is the preferred choice for critical applications in:

- Chemical Processing: Ideal for acid-resistant linings, reaction vessels, and heat exchangers exposed to hydrochloric, sulfuric, and nitric acids.

- Electronics & Semiconductor: Used in sputtering targets, capacitors, and vacuum system components due to excellent conductivity and purity.

- Medical Equipment: Suitable for surgical implants and instruments thanks to its outstanding biocompatibility.

- Aerospace & Defense: Employed in propulsion systems, high-temperature shields, and structural components.

- Energy & Environmental Engineering: Essential in nuclear energy systems and corrosion-resistant assemblies for clean energy technologies.

Key Advantages:

- Excellent corrosion resistance to most acids

- High melting point and thermal stability

- Superb workability and weldability

- Long service life and minimal maintenance

- Compliance with ASTM B708 standards for quality consistency

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye Metal Material Co., Ltd. manufactures tantalum alloy plates through a rigorous and standardized process, ensuring optimal performance and precision:

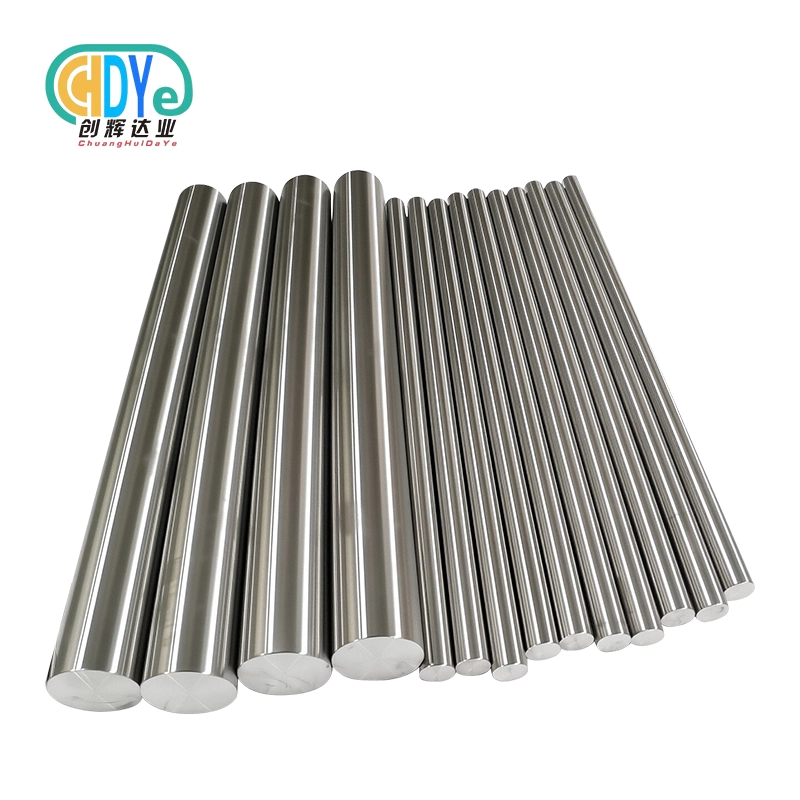

- Raw Material Selection: High-purity tantalum and alloying elements (Ta-2.5W, Ta-10W, Ta-Nb) are selected according to ASTM B708.

- Melting & Refining: Electron beam or vacuum arc melting (EBM/VAM) ensures purity and homogeneity.

- Forging & Rolling: Hot and cold rolling refines the grain structure, improving mechanical strength and flatness.

- Annealing: Vacuum annealing enhances ductility and stress relief.

- Surface Finishing: Grinding, polishing, or chemical cleaning for smooth, contamination-free surfaces.

- Dimensional Cutting: Precision cutting to specified sizes with strict tolerance control.

- Inspection & Testing: Each plate undergoes mechanical, dimensional, and non-destructive testing.

- Packaging: Vacuum sealing and export-grade packing for shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is embedded into every step of production under our ISO 9001:2015 certified management system.

Our comprehensive inspection program includes:

- Chemical Composition Analysis: Verified by XRF, ICP, or spectrometer to ensure conformity with ASTM B708.

- Mechanical Property Testing: Tensile strength, elongation, and hardness testing to guarantee performance.

- Dimensional Tolerance Check: Accurate to ±0.02 mm, ensuring plate uniformity.

- Surface Quality Control: Visual inspection for flatness, uniform texture, and defect-free surfaces.

- Non-Destructive Testing (NDT): Ultrasonic and eddy current testing for internal flaw detection.

- Final Review: Documentation and quality certification before dispatch.

All tantalum alloy plates are supplied with Mill Test Certificates (EN 10204 3.1) and optional third-party inspection reports (SGS, BV, TUV).

R&D and Customization

Driven by 30+ years of technical experience, our R&D team continues to advance material science in refractory metals. We specialize in:

- Custom Alloy Design: Tailoring Ta-W, Ta-Nb, and Ta-Mo compositions for enhanced strength or corrosion resistance.

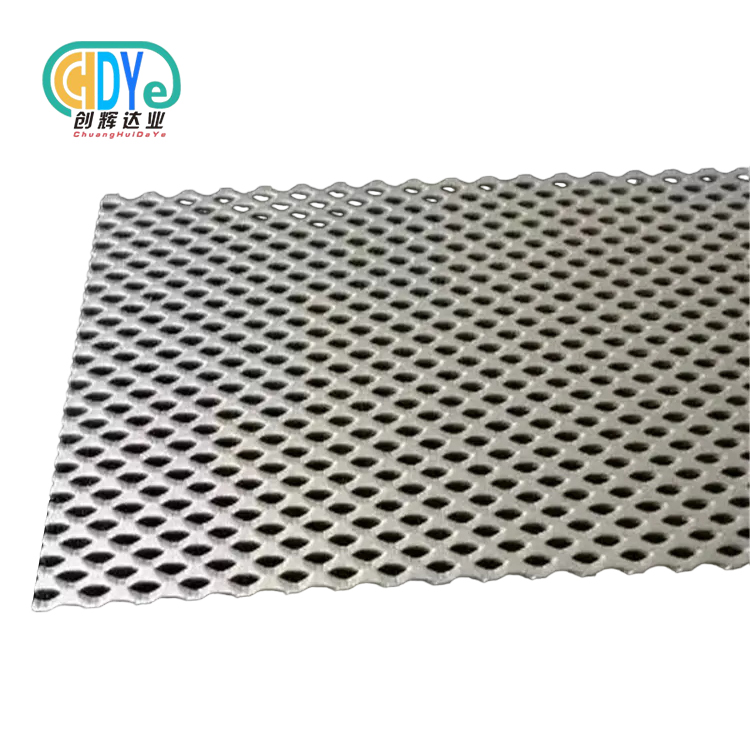

- Precision Fabrication: Tantalum plate machining, punching, and deep processing upon request.

- Surface Treatments: Polishing, passivation, or sandblasting to meet client-specific performance needs.

- Dimensional Customization: Thickness range from 0.5 mm to 40 mm, width up to 1200 mm, length up to 3000 mm.

- Joint Development: Collaborative R&D with universities and industrial research centers for cutting-edge applications.

Packaging & Global Logistics

To ensure every tantalum plate arrives in perfect condition, we use international-standard packaging and logistics solutions:

Packaging:

- Vacuum-sealed or anti-rust wrapping

- Foam padding for edge protection

- Strong wooden crates suitable for export

Labeling: Each crate labeled with grade, specification, heat number, and inspection report.

Shipping Options:

- Air Freight: For urgent global delivery within 7 days

- Sea Freight: For bulk shipments at competitive cost

- Courier Express: For small sample orders

- Export Experience: Products shipped to 50+ countries, including the USA, Germany, France, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers full OEM/ODM services to meet the requirements of industrial buyers and research institutions worldwide:

- Custom grades and alloy ratios (Ta, Ta-2.5W, Ta-10W, Ta-Nb)

- Special dimensions, shapes, and finishes per drawing

- Prototype & low-volume trial production

- Material and application consultation

- Rapid sample preparation and quotation

- Complete traceability and documentation support

Our engineering and production teams work closely with clients to deliver tailored, high-performance solutions on time and within budget.

Inspection Process

Each ASTM B708 Tantalum Alloy Plate undergoes a detailed inspection routine:

- Raw Material Verification – Spectrographic chemical composition analysis

- Melting Quality Audit – EB furnace or VAR process monitoring

- Dimensional Measurement – Using micrometer and ultrasonic thickness gauges

- Surface & Flatness Testing – Visual, mechanical, and NDT verification

- Mechanical Property Evaluation – Tensile and yield strength confirmation

- Documentation Review – MTC and quality certification preparation

- Final Approval & Packing – Verified by quality engineers prior to shipment

Why Choose Us

- 30+ Years of Rare Metal Expertise

- Comprehensive In-House Production: Melting, rolling, machining, and testing

- ISO 9001:2015 Certified Quality Management

- Strict Conformity to ASTM, AMS, and GB Standards

- Fast Delivery (7–15 days) with reliable international logistics

- Global Presence in 50+ Countries

- Skilled Engineering Team providing OEM design and support

- Competitive Pricing with 100% Quality Assurance

|

|

|

|

|

|

FAQs

Q1: What grades of tantalum plates do you offer?

A1: We supply Ta, Ta-2.5W, Ta-10W, and Ta-Nb grades, all in compliance with ASTM B708 and ASTM B521.

Q2: What surface finishes are available?

A2: Available finishes include bright, polished, matte, and pickled, depending on the application requirements.

Q3: What are the standard dimensions?

A3: Thickness 0.5–40 mm, width up to 1200 mm, length up to 3000 mm; customized sizes available.

Q4: Can you provide small or prototype quantities?

A4: Yes, we support small orders and trial production for research and testing.

Q5: Do you provide third-party inspection?

A5: Yes, SGS, BV, or TUV inspections can be arranged. Mill Test Certificates are provided with all shipments.

Q6: What are your delivery times?

A6: Typically 7–15 days for standard orders; expedited service available upon request.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email