- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

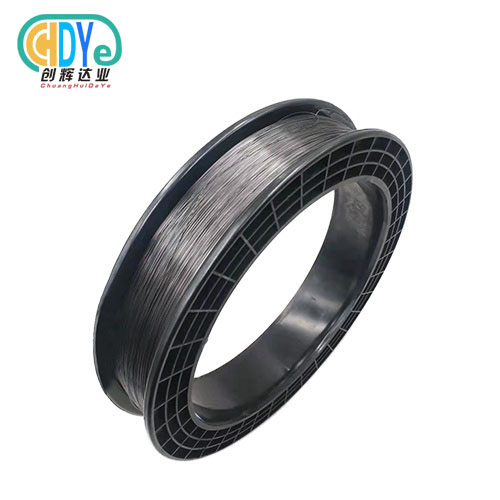

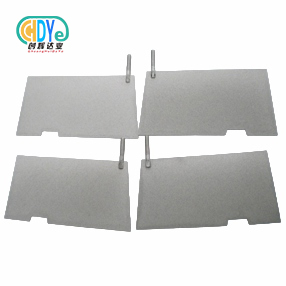

Pure Tantalum Plate

Size:Thickness 0.5-20mm*width50-1200*Length30-2500mm

Product Introduction

Our Pure Tantalum Plate is a high-performance, corrosion-resistant metal material designed for demanding industrial and scientific applications. Manufactured from ultra-high purity tantalum, this plate offers exceptional resistance to acids, high temperatures, and aggressive chemical environments. Its superior ductility and thermal conductivity make it ideal for applications in chemical processing equipment, aerospace components, electronics, and medical devices. With precise dimensions, smooth surface finish, and consistent mechanical properties, the Pure Tantalum Plate is engineered to meet the strictest quality standards and deliver reliable, long-lasting performance for global customers.

Specification:

|

Product Name |

pure tantalum plate |

|

Purity |

99.95% min |

|

Standard |

ASTM B708 |

|

Size |

Thickness 0.5-20mm*width50-1200*Length30-2500mm |

|

Condition |

1.Hot-rolled/Cold-rolled; 2.Alkaline Cleaning |

|

Customized products |

According to drawing, Special requirements to be agreed upon by the supplier and buyer. |

Pure tantalum plate Application

*It is used for laboratory equipment

*It is used for manufacturing heating elements,insulating parts,and loading vessels for vacuum furnaces.

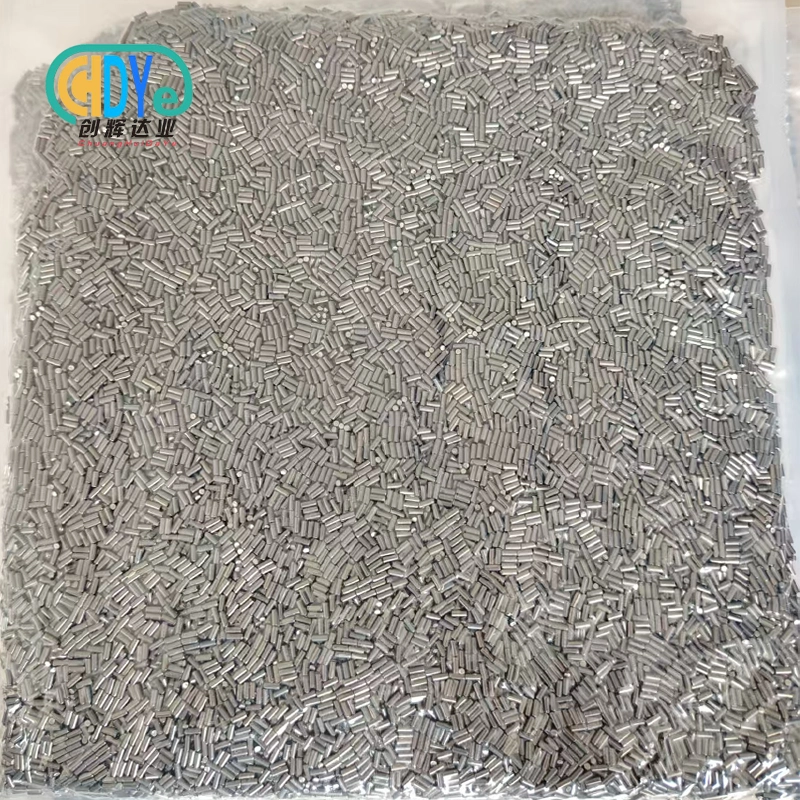

*It is used for manufacturing superalloys and electron-beam melting,super alloy additive.

*Used in metallurgical,machinery processing,glass,and ceramic industries.

*Used for sputtering targets.

Our Products

Application Advantages

The Pure Tantalum Plate offered by Shaanxi Chuanghui Daye exhibits exceptional corrosion resistance in strong acids and high-temperature environments, making it suitable for chemical processing, aerospace components, medical devices, and electronics. Its superior ductility, thermal conductivity, and excellent mechanical strength ensure long-term reliability in demanding applications. The Pure Tantalum Plate is widely recognized for its consistent performance and high purity, providing a dependable solution for industrial and research purposes.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

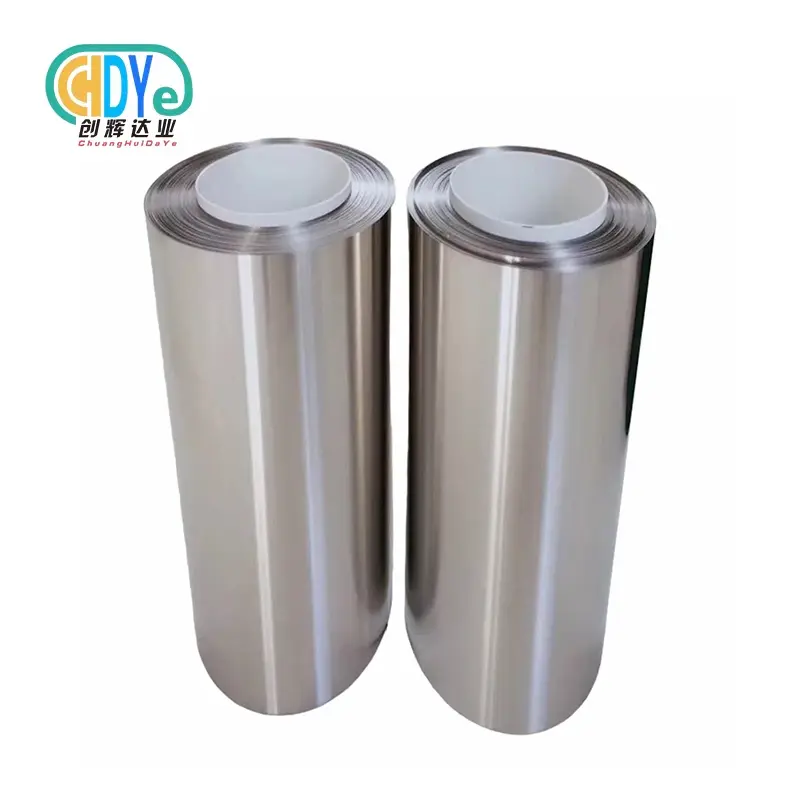

Manufacturing & Process Flow

Our production of Pure Tantalum Plate adheres to ASTM, ISO, and GB standards to ensure high quality:

Raw Material Selection: Only high-purity tantalum ingots are sourced.

Melting and Refining: Vacuum or electron beam melting ensures impurity-free material.

Hot Rolling & Forging: Optimized for uniform thickness, density, and mechanical properties.

Cold Rolling & Annealing: Enhances ductility, surface finish, and structural integrity.

Final Machining & Surface Treatment: Polishing and cleaning to meet stringent industrial standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Pure Tantalum Plate undergoes rigorous testing to guarantee reliability and compliance:

Chemical composition analysis using optical emission spectrometry.

Mechanical property verification including tensile strength, hardness, and elongation.

Surface inspection for defects, inclusions, or contamination.

Non-destructive testing methods such as ultrasonic or eddy current inspections.

R&D and Customization

Our R&D team continuously improves the performance of Pure Tantalum Plate to meet specialized industrial needs:

Custom thicknesses from 0.5 mm to 50 mm.

Widths and lengths tailored to client specifications.

Adjusted mechanical and thermal properties for unique operating conditions.

Consultation and prototype support for advanced engineering applications.

Packaging & Global Logistics

Each Pure Tantalum Plate is securely packed to prevent corrosion and mechanical damage:

Vacuum-sealed or wrapped in anti-rust film with foam padding.

Packed in export-standard wooden crates with clear labeling.

Reliable shipping via air, sea, or land to more than 50 countries.

Tracking and logistics support ensure safe and timely delivery.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides full OEM and customization services for Pure Tantalum Plate:

Manufacturing per client drawings, grades, or technical requirements.

Small-batch, large-batch, or prototype production with consistent quality.

Surface finishing, spooling, and packaging customization options.

Comprehensive support from material selection to final delivery.

Inspection Process

The inspection process for Pure Tantalum Plate includes:

Incoming material verification for purity and traceability.

In-process dimensional and structural checks during rolling and forging.

Mechanical testing and surface quality assessment post-annealing.

Final audit before shipment to ensure conformity with ASTM, ISO, or GB standards.

Why Choose Us

Over 30 years of experience in rare metal production.

ISO 9001:2015 certified manufacturing system.

Fast 7-day delivery for standard products.

Exported to 50+ countries with a strong global reputation.

Professional OEM and technical support at competitive prices.

|

|

|

|

|

|

FAQs

Q1: What purity levels are available for the tantalum plates?

A1: Standard purity is 99.95%, with 99.99% ultra-high purity available upon request.

Q2: What sizes do you offer?

A2: Thickness ranges from 0.5 mm to 50 mm, and width and length can be customized.

Q3: Can you provide small-batch or prototype orders?

A3: Yes, we support small-batch and prototype production for testing or research purposes.

Q4: How long is the production lead time?

A4: Standard Pure Tantalum Plate items can be shipped within 7 days; custom orders require additional time.

Q5: Which industries use your tantalum plates?

A5: Aerospace, electronics, chemical processing, medical equipment, and research laboratories.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email