- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

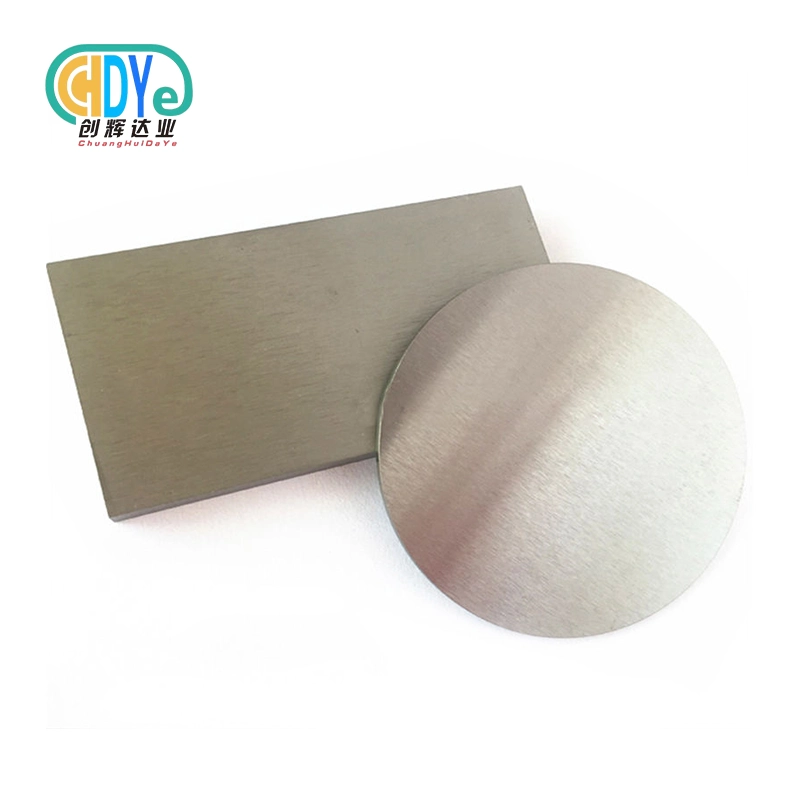

Platinum Coated Titanium Anode

. MMO coated anode has long working life.For the important, the substrate could be reused.

Product Introduction

Chdymetal can provide various titanium anodes, customized is accepted. titanium anode use pure titanium material as substrate, has high anti-corrosion and high catalytic activity. MMO coated anode has long working life .For the important, the substrate could be reused.

|

Substrate:pure titanium Gr1 |

coating: Pt |

|

Current density: ≤1000 A/m² |

Coating thickness ≥0.2μm |

|

Coating thickness:0.2-5μm |

Oxygen evolutionpotential1.68 v relative to calomel electrode? |

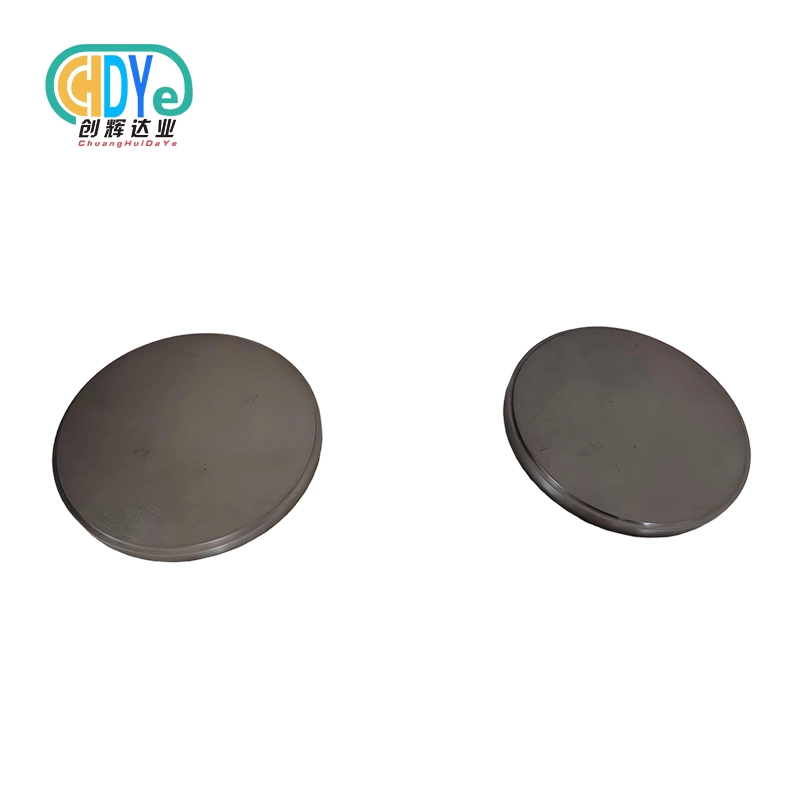

Platinum coated titanium anode Features

Platinum coated titanium anode has high electric catalytic performance, strong antioxidant property, good electric conductivity and long working life span. Titanium as the substrate and precious oxide as the coating, advantages of titanium anode are obvious for its small weight, strong tensile strength, good anti-resistance and excellent performance especially anti- wet chlorine resistance. Under condition of water electrolysis, small amount of chloride ions will make pitting corrosion to stainless steel thus lead to the working failure and this will not happen to titanium anode. Platinum group oxide that added to the coating make high current efficiency, electric conductivity, electro-catalytic property, anti-oxidation and long working life, power consumption is reduced a lot.

Platinum coated titanium anode Advantages

1) Good electric conductivity

2) Good anti-corrosion property

3) Strong tensile strength and good processing performance

4) Long life span and polarity reverse

5) Good electro-catalytic property

Platinum coated titanium anode packing

|

|

|

Application Advantages

Platinum Coated Titanium Anode combines the mechanical strength of titanium with the superior catalytic and corrosion resistance of platinum. It is widely used in electrochemical processes that require high performance and stability under harsh conditions.

Key Advantages:

- Exceptional electrochemical stability and corrosion resistance

- High current efficiency and low overpotential

- Long operational life in acidic and alkaline electrolytes

- Excellent adhesion between platinum coating and titanium substrate

- Reusable substrate—coating can be re-plated after wear

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Each Platinum Coated Titanium Anode is produced under a controlled electroplating and sintering process to ensure coating uniformity, purity, and durability.

Process Steps:

- Titanium Substrate Selection – High-purity Grade 1 or Grade 2 titanium.

- Surface Pretreatment – Degreasing, sandblasting, and acid pickling to improve coating adhesion.

- Electroplating Process – Platinum is electro-deposited onto the titanium surface under controlled voltage and current density.

- Heat Treatment – Thermal bonding enhances coating density and adhesion strength.

- Polishing and Testing – Surface inspection, thickness measurement, and adhesion verification.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Strict quality management ensures every anode meets international standards such as ASTM, ISO, and AMS.

Inspection Includes:

- Raw Material Verification: Chemical composition and purity testing.

- Coating Thickness: Measured by X-ray fluorescence or microscopy.

- Adhesion Test: Cross-cut and ultrasonic testing.

- Electrochemical Test: Current efficiency, potential, and life cycle testing.

- Dimensional & Visual Inspection: Full surface uniformity check before packaging.

R&D and Customization

Our R&D team continuously improves coating technology to achieve better performance in various electrolytic environments.

Available Customization:

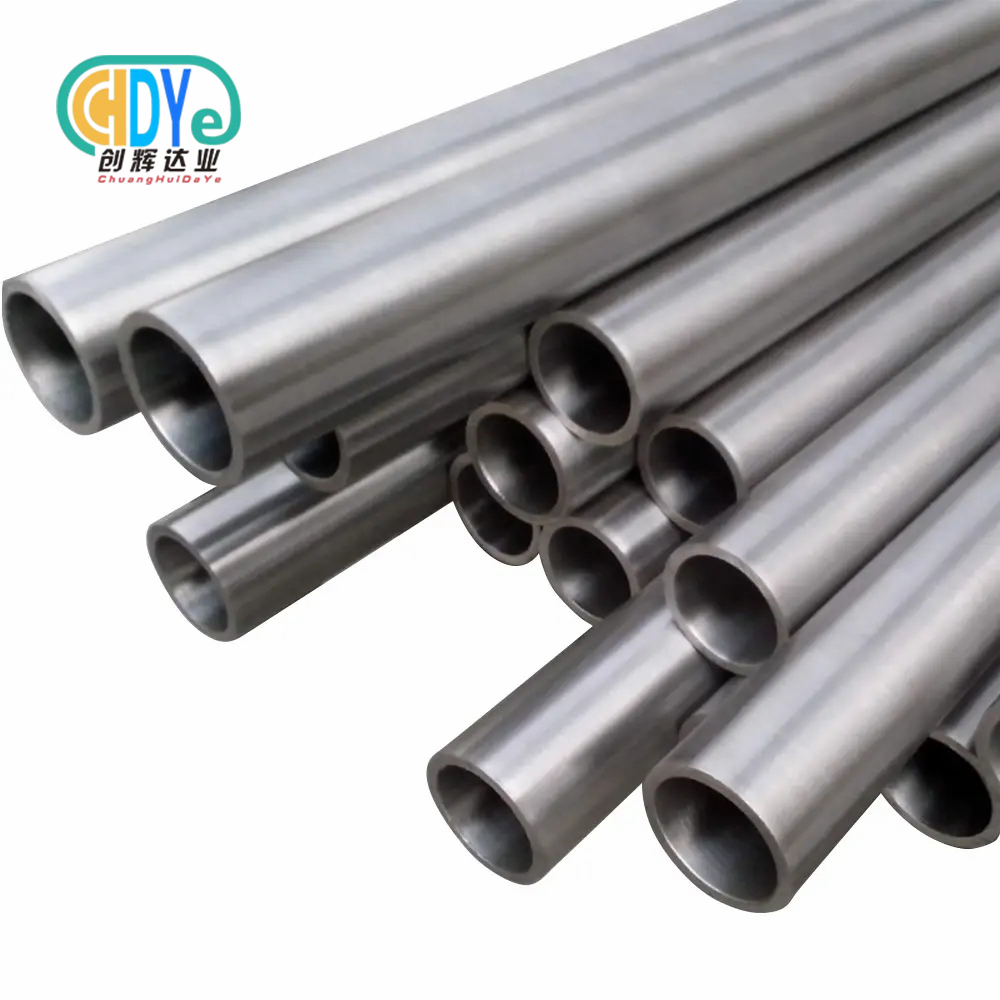

- Adjustable platinum thickness (0.5–10 μm)

- Mesh, plate, rod, or tube substrate shapes

- Customized substrate dimensions and hole patterns

- Tailored designs for specific electrolytic reactions (e.g., water electrolysis, fuel cells, and sensors)

- Platinum-iridium alloy or mixed coatings upon request

Packaging & Global Logistics

Every Platinum Coated Titanium Anode is securely packed to protect it from mechanical damage and oxidation during shipment.

Packaging Details:

- Vacuum-sealed or anti-rust film wrapping

- Foam padding and moisture-proof barrier

- Export-standard wooden crates or cartons

- Clear labeling with product specifications and batch code

Logistics Services:

- Global air, sea, and courier shipping options

- Flexible Incoterms (EXW, FOB, CIF, DDP)

- On-time delivery tracking and full documentation support

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide comprehensive OEM and ODM services for different industrial applications.

OEM Capabilities:

- Customized anode shapes (mesh, rod, plate, or wire)

- Personalized marking and labeling

- Platinum-iridium or multi-layer coatings

- Engineering support for new product development

- Technical consultation and performance optimization

Inspection Process

To ensure consistent quality, each anode undergoes full inspection before delivery.

Standard Testing Procedures:

- Visual inspection for defects or uneven coating

- Coating thickness and uniformity measurement

- Adhesion and bonding strength test

- Electrochemical performance evaluation

- Final verification and traceable documentation

Why Choose Us

- Over 30 years of expertise in rare and precious metal anodes

- Certified ISO 9001:2015 quality management system

- Advanced plating and testing equipment

- 7–10 day fast production and delivery cycle

- Exports to 50+ countries worldwide

- Professional technical support and after-sales service

|

|

|

|

|

|

FAQs

Q: What is the thickness of platinum coating?

Q:Can i get a sample?

Q: What are your express delivery methods?

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email