- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

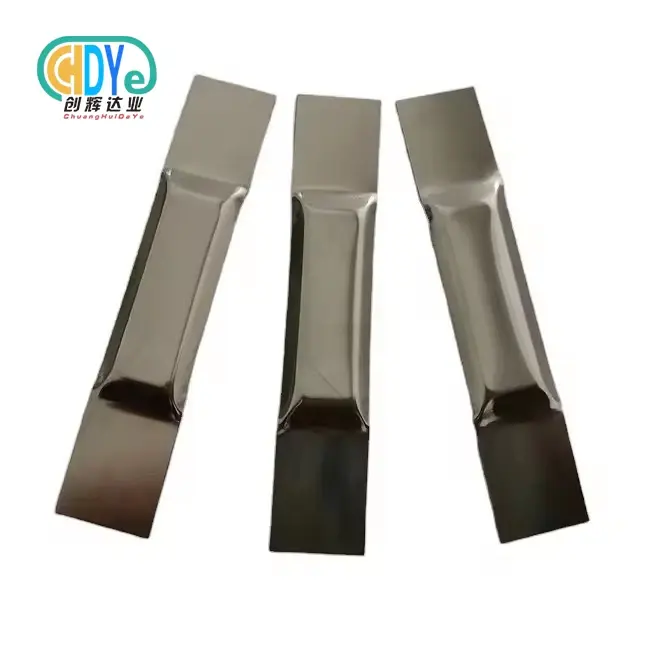

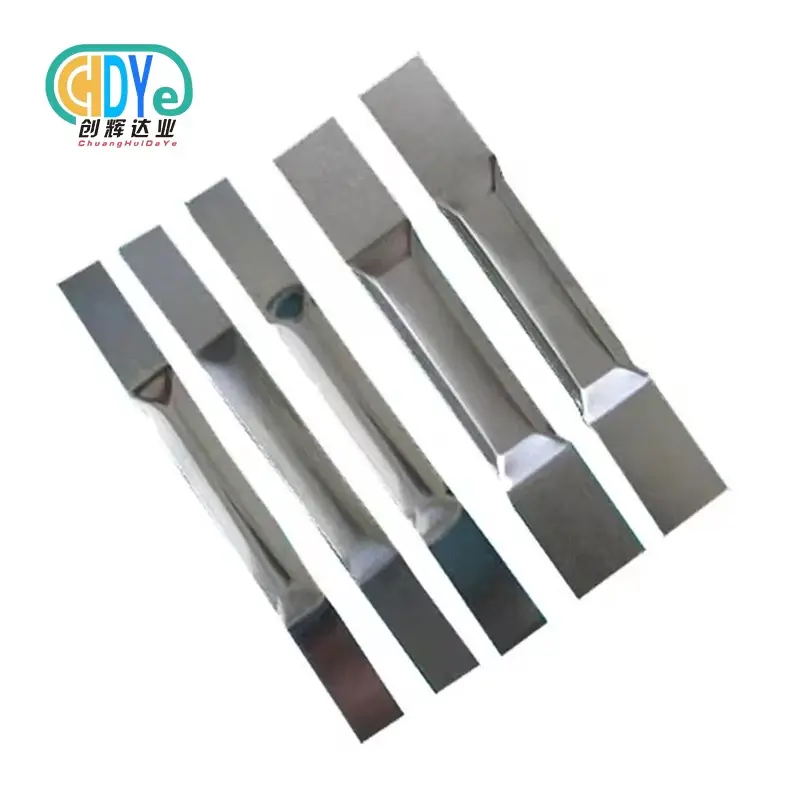

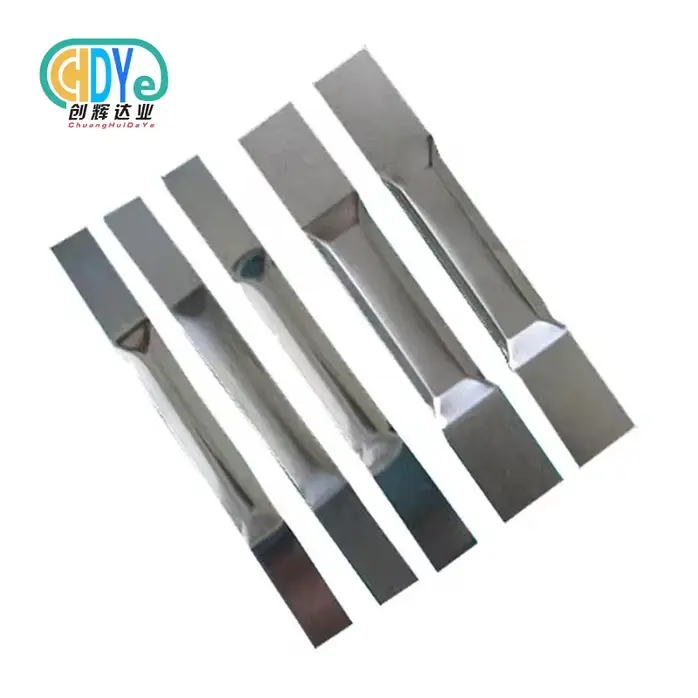

Tungsten Boat For Evaporation

Product Introduction

The tungsten boat for evaporation from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a precision-engineered component made from ultra-high-purity tungsten. Designed for high-temperature and vacuum applications, it offers exceptional thermal stability, excellent chemical resistance, and precise dimensional integrity under extreme conditions. Manufactured to meet rigorous international standards, this tungsten boat for evaporation ensures reliable performance in advanced material processing and research laboratories.

With a melting point of approximately 3422°C, the boat can withstand prolonged exposure to intense heat without warping or chemical degradation. Its high thermal conductivity and mechanical stability make it suitable for applications that demand contamination-free and consistent evaporation processes.

|

Product purity |

>99.95% |

|

Minimum order |

1Kg |

|

colour |

natural color |

|

Certification system |

ISO9001:2015 |

|

package |

Wooden Case/ Carton |

|

surface |

Alkali washing |

|

Whether to receive samples |

Accept |

|

Supply market area |

Global |

|

Product density |

19.2g/cm³ |

|

Packing |

Soft foam inside, carton or wooden box outside |

|

Size |

Customize |

Application Advantages

This tungsten boat for evaporation is widely used across several industries due to its superior material properties:

- Semiconductor Manufacturing: Ideal for thin-film deposition and high-purity metal evaporation in vacuum systems.

- Electronics and Coating Industries: Suitable for electronic material preparation and specialty metal coatings.

- Research Laboratories: Perfect for experiments requiring ultra-clean, high-temperature environments.

- Specialty Materials: Utilized for evaporating rare metals, alloys, and advanced materials where thermal stability is critical.

Its resistance to corrosion, thermal stress, and chemical reactions ensures consistent results in both industrial and research settings.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of this tungsten boat for evaporation follows a meticulous process to guarantee high performance and longevity:

- Material Selection: Ultra-high-purity tungsten ingots are inspected for chemical composition and structural integrity.

- Melting & Casting: Tungsten is melted in an electron beam furnace and cast into preliminary shapes.

- Forging & Rolling: Advanced techniques improve mechanical strength and dimensional precision.

- Machining & Forming: CNC and precision lathes shape the boat to exact specifications.

- Surface Treatment: Polishing and degassing remove impurities and ensure a clean, smooth surface.

- Final Inspection: Each boat undergoes dimensional, mechanical, and purity checks before packaging.

This process ensures optimal thermal performance and structural stability for high-temperature evaporation operations.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye maintains strict quality control procedures, certified under ISO 9001:2015, to ensure every product meets international standards:

- Raw Material Testing: Verification of tungsten purity and chemical composition.

- Dimensional Checks: Precise measurement of thickness, length, and curvature.

- Thermal & Mechanical Testing: Simulated high-temperature conditions to assess durability.

- Surface Quality Inspection: Detects microcracks, roughness, and potential contamination.

- Batch Traceability: Each unit is labeled with a batch number and production date for full traceability.

These measures guarantee that each boat delivers consistent, high-quality performance.

R&D and Customization

Chuanghui Daye provides tailored solutions through its experienced R&D team, enhancing the design and performance of these boats:

- Custom dimensions, wall thickness, and shapes for specific evaporation systems.

- Surface treatments to optimize thermal conductivity or reduce contamination risks.

- Prototype and small-batch production for research or pilot projects.

- Technical guidance on material selection and process optimization.

Continuous innovation allows us to meet evolving industrial and laboratory requirements efficiently.

Packaging & Global Logistics

Every boat is carefully packaged to ensure safe delivery:

- Wrapped in vacuum or anti-rust film to prevent oxidation.

- Foam protection and custom cushioning to avoid damage during transport.

- Packed in reinforced wooden crates suitable for air, sea, and land shipping.

- Clear labeling with specifications, batch numbers, and handling instructions.

Reliable logistics partners enable timely delivery to more than 50 countries, including the United States, Germany, France, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Chuanghui Daye offers OEM and customization services to meet diverse requirements:

- Custom sizes, grades, and drawings.

- Prototype development and small-batch manufacturing.

- Technical consultation for design, material selection, and process optimization.

- Post-sales support for proper usage and maintenance.

These services ensure each tungsten boat for evaporation is perfectly suited to customer-specific applications.

Inspection Process

Each boat undergoes a comprehensive inspection to guarantee quality and performance:

- Incoming material verification for purity and composition.

- Dimensional measurement according to design specifications.

- Thermal and mechanical testing to simulate high-temperature use.

- Surface inspection for microcracks and potential contaminants.

- Final review and secure packaging for shipment.

This rigorous process ensures consistent reliability for industrial and laboratory evaporation operations.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers unmatched expertise and advantages:

- Over 30 years of experience in rare metal manufacturing.

- ISO 9001:2015 certified quality management system.

- Advanced production equipment, including electron beam furnaces, lathes, and rolling machines.

- Export experience to 50+ countries worldwide.

- OEM/ODM support and professional technical consultation.

- Commitment to on-time delivery, cost efficiency, and high-quality products.

Our focus on quality, reliability, and innovation makes us a trusted global supplier of tungsten evaporation solutions.

|

|

|

|

|

|

FAQs

Q1: What is the material used for the boat?

A1: The boat is made of ultra-high-purity tungsten, ensuring high thermal and chemical resistance.

Q2: Can I order custom sizes or shapes?

A2: Yes, we provide OEM/ODM services for dimensions, wall thickness, and designs tailored to your process.

Q3: Which industries use these boats?

A3: They are commonly used in semiconductors, electronics, thin-film deposition, vacuum systems, and research labs.

Q4: How is the product packaged for shipping?

A4: Each boat is wrapped with vacuum or anti-rust film, cushioned with foam, and shipped in reinforced wooden crates.

Q5: Do you offer technical support?

A5: Yes, our engineers provide guidance on material selection, process optimization, and troubleshooting for maximum efficiency.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email