- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Basket

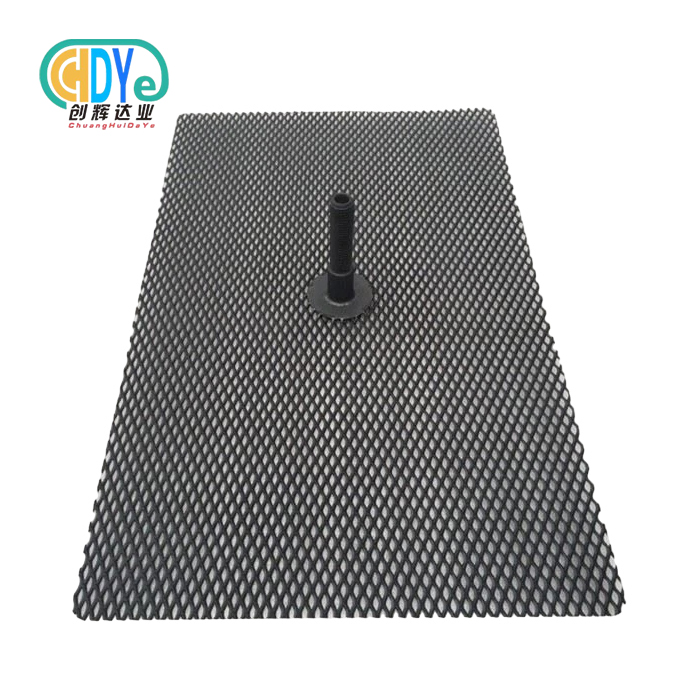

2. The main components of the product: titanium mesh plate, frame plate, hook 3 parts

3. Production method: argon arc welding

4. Size: can be customized according to customer requirements drawing

Overview

The titanium basket is a precision-engineered container made from titanium or titanium alloy mesh, designed for high corrosion resistance, strength, and long-term durability in electroplating, chemical, and filtration processes.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a professional manufacturer and supplier of titanium baskets used in various industries such as electroplating, water treatment, and chemical processing.

Our titanium baskets are known for their lightweight structure, excellent conductivity, and outstanding resistance to acids, alkalis, and chlorides—making them an ideal choice for applications where conventional stainless steel fails.

Types of Titanium Baskets

We manufacture and supply a wide range of titanium baskets according to application, shape, and structure:

-

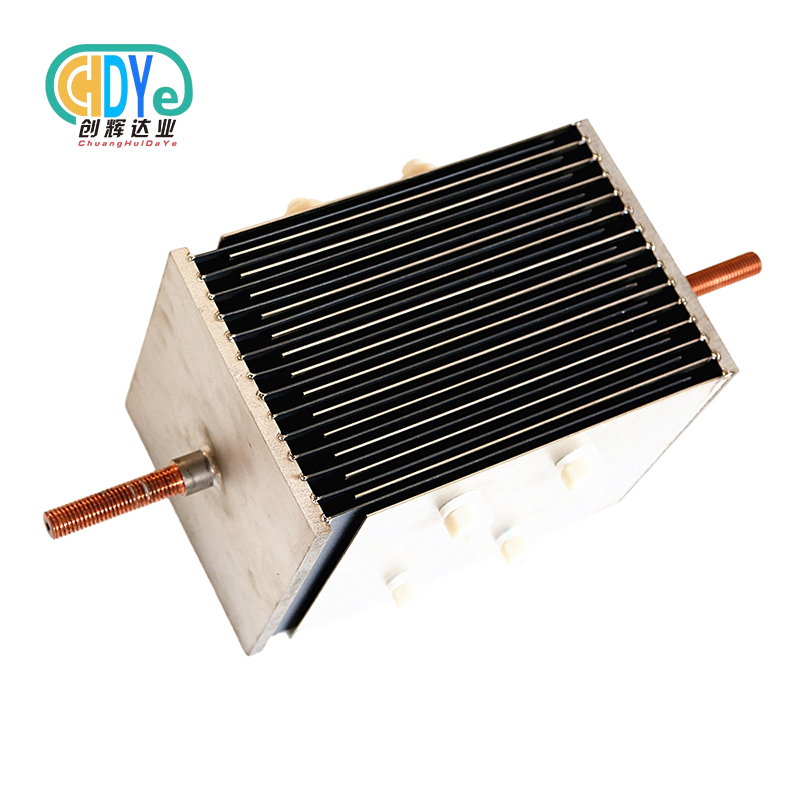

Titanium Anode Basket – Used for electroplating baths, ensuring uniform current distribution.

-

Perforated Titanium Basket – Designed for filtration, cleaning, and material handling.

-

Mesh-Type Titanium Basket – Lightweight, high-flow design suitable for electrolytic or ion exchange processes.

-

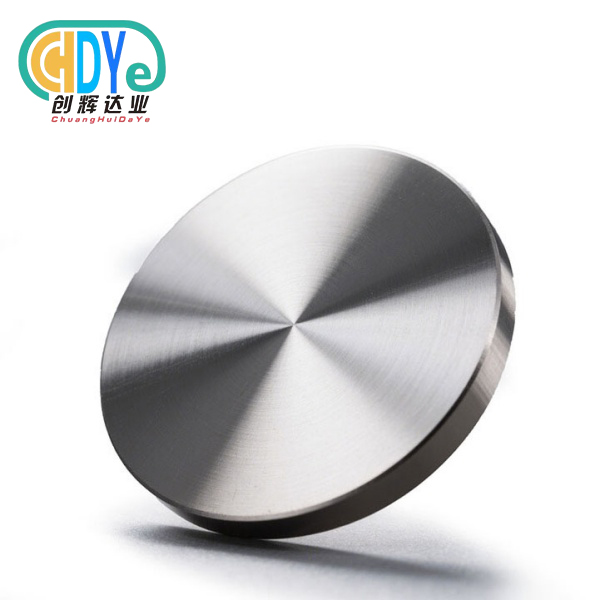

Round Titanium Basket / Cylindrical Basket – For barrel plating and acid-based production lines.

-

Customized Titanium Basket – Tailored size, shape, and mesh density based on customer requirements.

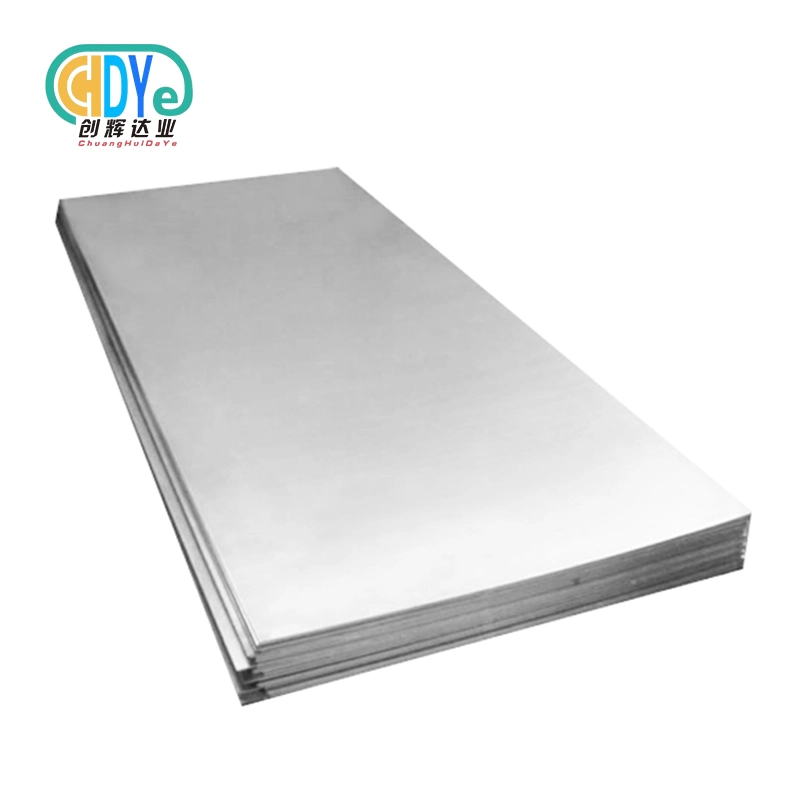

Technical Specifications

| Item | Specification |

|---|---|

| Material Grades | Gr1, Gr2, Gr7, Gr9, Gr12 |

| Standards | ASTM B265 / ASTM B348 / ASTM B338 / ISO 9001 |

| Structure | Mesh, Perforated Plate, Wire Frame |

| Mesh Opening | 0.5 mm – 5 mm |

| Diameter | 50 mm – 800 mm |

| Height | Up to 1200 mm or customized |

| Thickness | 0.5 mm – 5 mm |

| Connection | Welding, Riveting, or Titanium Fastener Assembly |

| Surface Treatment | Pickled, Polished, Sandblasted |

| Working Temperature | Up to 400°C |

| Optional Coating | MMO (Mixed Metal Oxide), Platinum, Iridium, Ruthenium |

Each titanium basket is produced with precise welding, strong joints, and uniform mesh tension to ensure consistent strength and durability.

1. Grade: Gr1,Gr2

2. The main components of the product: titanium mesh plate, frame plate, hook 3 parts

3. Production method: argon arc welding

4. Size: can be customized according to customer requirements drawing

5. Features of titanium basket:

The titanium basket is made of high quality GR2 industrial pure titanium with purity up to 99.7% and strong corrosion resistance. It is suitable for loading anode materials in various electroplating tanks.

The use of precision welding technology, welding joint close, firm;

According to customer requirements in the titanium blue port for anti-theft design;

6. Notes when using titanium basket:

1) The titanium basket mouth should be slightly higher than the liquid level to prevent anode slag outflow.

2) The lower end of the titanium basket should be 100~150mm higher than the parts to avoid excessive concentration of current at the lower end of the parts, resulting in burning.

3) The titanium basket and the anode should be in close contact, otherwise the anode potential on the titanium blue will rise sharply, so that the titanium basket surface oxygen evolution and chlorine evolution reaction, causing the damage of the titanium basket and the oxidation of additives.

Titanium basket various type

Product Highlights

- Corrosion Resistance: Titanium baskets can withstand strong acids and alkalis, especially in electroplating environments containing nickel, copper, and gold.

- High Strength-to-Weight Ratio: Provides structural integrity while remaining lightweight for easy handling.

- Excellent Electrical Conductivity: Ensures uniform current flow and efficient plating results.

- Custom Design Options: Various mesh sizes, shapes, and handles available for specific processes.

- Maintenance-Free: Resistant to scaling, oxidation, and pitting—resulting in longer service life.

- Eco-Friendly Material: 100% recyclable and non-toxic, suitable for green industrial processes.

Applications

Titanium baskets are widely used across multiple industries for handling, filtration, and electrochemical applications.

- Electroplating & Metal Finishing: As anode baskets for nickel, copper, zinc, and gold plating lines.

- Chemical Processing: Storage and filtration of corrosive materials and chemical media.

- Water Treatment Systems: Filtration and ion exchange in seawater and wastewater plants.

- Pharmaceutical & Food Industries: Clean, non-contaminating containers for reaction processes.

- Aerospace & Electronics: Used in etching, anodizing, and electrochemical surface treatments.

- Laboratory Applications: Corrosion-resistant carriers for high-purity chemical environments.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

At Shaanxi Chuanghui Daye, every titanium basket is crafted using advanced forming and welding techniques:

- CNC Cutting & Forming: Ensures precision mesh shaping and dimensional accuracy.

- Automatic TIG Welding: Produces clean, strong welds with minimal distortion.

- Pickling & Passivation Treatment: Enhances corrosion resistance and removes surface impurities.

- MMO Coating Application: Optional for electroplating or anodizing performance enhancement.

- Dimensional Verification: 100% inspection of roundness, mesh alignment, and handle strength.

We support both prototype fabrication and mass production, delivering consistent quality to global OEMs and end-users.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Our titanium baskets comply with ISO 9001:2015 and ASTM standards. Each product undergoes comprehensive testing and inspection:

- Material verification via spectrometer analysis

- Welding integrity check and leak testing

- Dimensional and tolerance inspection

- Surface roughness and coating adhesion tests

- Load-bearing and stress performance evaluation

Every batch is accompanied by mill test reports and traceable serial numbers for full transparency.

Customization Options

We understand that every industrial process is unique. Therefore, we provide fully customized titanium baskets to meet your operational requirements:

- Custom size, shape, and mesh density

- Choice of solid plate or woven mesh structure

- Optional handle, hook, or frame configurations

- Platinum, Iridium, or MMO coatings for improved performance

- Integration with titanium anode assemblies or filter units

- Prototype and batch production with short lead times

- Our engineering team offers design optimization assistance to help you achieve maximum process efficiency.

Packaging & Global Logistics

We ensure safe delivery and product protection during transportation:

- Packaging: PE wrap, foam padding, and export-standard wooden crates

- Labeling: Includes product code, dimensions, and heat number

- Shipping: By sea, air, or express courier with international tracking

- Delivery Time: 5–10 working days for standard sizes, 15–20 days for customized designs

All packaging materials comply with international shipping standards to avoid damage and contamination.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Why Choose Shaanxi Chuanghui Daye

-

Over 30 years of experience in titanium fabrication and electrochemical components

-

Full control from raw material melting to final assembly

-

ISO 9001:2015-certified production and inspection system

-

Global export network covering 50+ countries

-

OEM & ODM service for electroplating equipment manufacturers

-

Fast quotation, flexible customization, and technical support

We are committed to providing reliable titanium basket solutions that enhance your operational performance and reduce maintenance costs.

FAQs

Q1: What is the advantage of using a titanium basket in electroplating?

A1: It provides superior corrosion resistance and even current distribution, resulting in consistent plating thickness and quality.

Q2: Can titanium baskets handle strong acids like hydrochloric or sulfuric acid?

A2: Yes, titanium resists most strong acids and alkalis, making it ideal for harsh chemical environments.

Q3: Do you offer titanium baskets with MMO or platinum coatings?

A3: Yes, we can apply MMO, platinum, iridium, or mixed coatings upon request for enhanced electrochemical performance.

Q4: Are your baskets suitable for automated plating systems?

A4: Absolutely, we design baskets compatible with both manual and automated plating lines.

Q5: Can you customize the basket size and mesh opening?

A5: Yes, all titanium baskets can be customized in size, shape, and mesh density according to client drawings or samples.

|

|

|

|

|

|

FAQs

Q1: What standards do your tubes conform to?

A1: We produce according to ASTM B338, ASTM B861, and AMS 4942, ensuring full international compliance.

Q2: Can you supply small quantities for trial use?

A2: Yes, we support sample and small-batch production for testing and R&D projects.

Q3: What is your typical lead time?

A3: Standard sizes can be shipped within 7 days; customized orders typically take 2–3 weeks.

Q4: Do you provide inspection certificates?

A4: Yes, all deliveries include EN 10204 3.1 inspection reports and chemical/mechanical test data.

Q5: What are your main export markets?

A5: We export to the United States, Germany, France, South Korea, Singapore, and more than 50 other countries worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email