- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Welding Wire

ERTi-1, ERTi-2, ERTi-3, ERTi-4, ERTi-5, ERTi-7, ERTi-9, ERTi-12

2.Standard: ASTM B863, AWS A5.16

3.Supply scope: Diameter 0.4~6.0mm x L, straight wire, natural coil, coil (D100/D300)

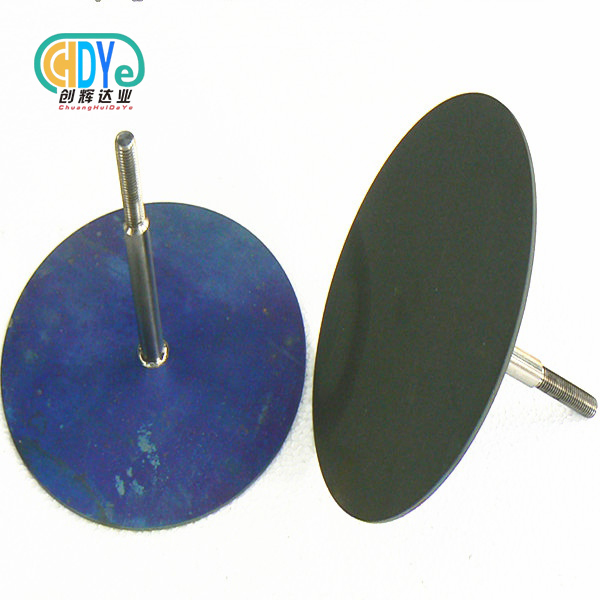

4.Surface treatment: pickled surface / bright surface

Product Overview

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading global manufacturer of Titanium Welding Wire, engineered for precision joining in aerospace, automotive, chemical, and medical industries. Produced in Baoji, China’s “Titanium Capital,” our welding wire combines superior corrosion resistance, consistent mechanical performance, and clean arc stability, complying with international standards including AWS A5.16, EN ISO 18274, and ISO 9001:2015.

Our Titanium Welding Wire ensures reliable weld quality for both critical and routine applications, supporting TIG, MIG, and laser welding processes. The wire’s uniform composition and excellent surface finish reduce contamination and spatter, providing seamless, high-strength joints.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grades | Gr1, Gr2, Gr5 (Ti-6Al-4V), Gr7, Gr9 |

| Diameter Range | 0.8 mm – 4.0 mm |

| Standard Length | 1 kg – 15 kg spools (custom sizes available) |

| Tensile Strength | ≥ 900 MPa (Gr5), ≥ 350 MPa (Gr2) |

| Elongation | 10% – 25% |

| Melting Point | 1,668°C |

| Surface Finish | Bright, oxide-free, smooth |

| Applications | TIG/MIG welding, laser welding |

| Certification | ISO 9001:2015, AWS, Material Test Report (MTC) |

Physical & Mechanical Performance

Our Titanium Welding Wire exhibits:

- Excellent ductility and fatigue resistance for repetitive welding applications

- Stable mechanical performance under cyclic and high-temperature conditions

- Non-magnetic and biocompatible features suitable for medical implants

- Superior corrosion resistance in acidic, saline, and high-temperature environments

This combination of properties ensures reliable welding performance and long-term joint integrity in demanding industrial applications.

Product Highlights & Advantages

-

Ultra-Pure Alloy Composition – Vacuum arc remelting and electron beam refining remove impurities for defect-free welds.

-

Uniform Diameter & Smooth Feeding – Multi-pass drawing and precise measurement eliminate feeding inconsistencies.

-

Enhanced Arc Stability – Optimized chemical composition reduces spatter and improves weld bead quality.

-

High Heat & Corrosion Resistance – Maintains strength and oxidation resistance in weld zones.

-

Multi-Welding Compatibility – Designed for TIG, MIG, and laser welding of titanium structures.

-

Surface Perfection – Bright, oxide-free surface ensures clean fusion without contamination.

-

Full Certification Support – Includes Material Test Reports, AWS, and ISO documentation.

Manufacturing & Process Flow

-

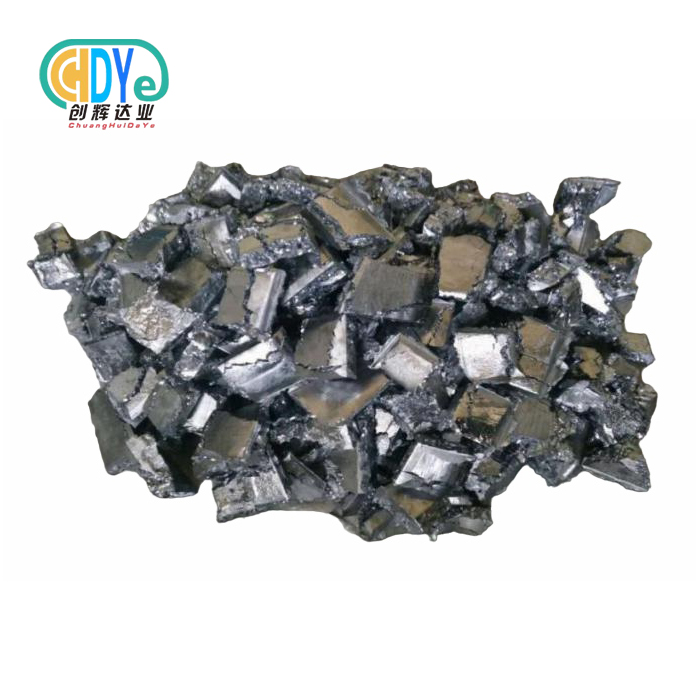

Raw Material Verification – High-purity titanium sponge or ingots from certified suppliers

-

Vacuum Arc Remelting – Ensures uniform composition and ultra-low impurities

-

Wire Drawing – Multi-stage drawing for precise diameter, concentricity, and surface smoothness

-

Intermediate Annealing – Relieves internal stresses and enhances ductility

-

Surface Conditioning – Oxide-free, bright finish for optimum welding performance

-

Spooling & Inspection – Dimensional, mechanical, and visual inspection for each spool

-

Traceability & Documentation – Every batch is fully traceable with MTC and certification

|

|

|

|

|

|

|

|

Quality Control & Inspection

- Chemical composition verified by ICP and spectrometer

- Mechanical properties: tensile, yield, and elongation tested

- Microstructure and grain analysis for uniformity

- Ultrasonic and eddy current inspections for defect detection

- Surface inspection to prevent weld contamination

- ISO 9001:2015-certified production ensures strict quality management

Application Advantages

- Aerospace: High-strength welded assemblies for airframes, fuel tanks, and control cables

- Medical & Dental: Surgical instruments, orthopedic implants, and dental prosthetics

- Chemical & Petrochemical: Corrosion-resistant welded piping, tanks, and reactors

- Automotive & Racing: Lightweight welded components such as frames, exhausts, and connectors

- Electronics & Semiconductor: High-purity welded parts for vacuum systems and heat sinks

- Marine Engineering: Seawater-resistant welded assemblies for submersible applications

Our welding wires are trusted by manufacturers in the U.S., Germany, Japan, South Korea, France, and Singapore, across 50+ countries.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

- Custom alloy grades, diameters, and spool weights for specialized welding needs

- Prototype and small-batch production for testing and R&D

- Technical guidance for TIG, MIG, and laser welding parameters

- OEM/ODM branding for distributors and manufacturers

- Surface treatment customization and packaging options

Our engineers work closely with clients from concept to production to optimize weld performance

Packaging & Global Logistics

To ensure safe and contamination-free delivery, we adopt international export packaging standards:

- Inner Layer: Vacuum-sealed or anti-rust film wrapping

- Intermediate Layer: Foam cushioning for shock protection

- Outer Case: Fumigation-free plywood or steel-reinforced boxes

- Marking: Clear labeling with alloy grade, dimension, heat number, and batch code

We cooperate with major logistics providers (DHL, FedEx, UPS, COSCO) to provide air and sea delivery options ensuring timely arrival to your destination.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Global Partnership & Case References

Aerospace: Ti-6Al-4V wire for fuselage assembly projects in Europe

Medical: Biocompatible welding wire for orthopedic devices in North America

Chemical Industry: Corrosion-resistant wire for tanks and pipelines in Southeast Asia

Why Choose Us

- 30+ years of titanium metallurgy and welding expertise

- Full-process production from melting to precision drawing

- ISO-certified manufacturing with complete traceability

- Competitive pricing without compromising quality

- Fast and reliable global logistics support

- Trusted by industrial clients in over 50 countries

- Expert technical consultation and customized solutions

|

|

|

|

|

|

FAQ

Q1: Is your welding wire compatible with TIG, MIG, and laser welding?

Yes. Our Titanium Welding Wire is optimized for all three welding processes.

Q2: Can spool size and weight be customized?

Yes. Standard spools range 1–15 kg, and custom sizes are available.

Q3: Do you provide test certificates?

Absolutely. Each batch includes ISO 9001:2015 certification, AWS compliance, and Material Test Reports.

Q4: How long is the delivery time?

Stock spools: 7–10 days; custom orders: 20–25 days, depending on specifications.

Q5: Can you assist with welding parameters?

Yes. Our engineers provide guidance on optimal current, voltage, shielding gas, and techniques for maximum weld quality.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email