- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

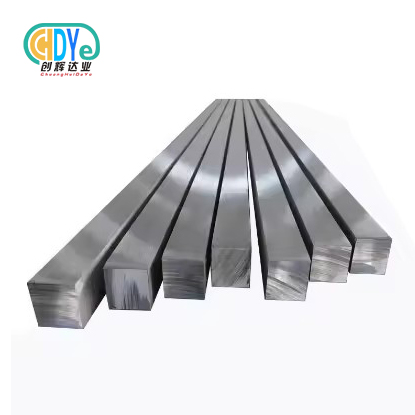

tantalum plates

Product Introduction

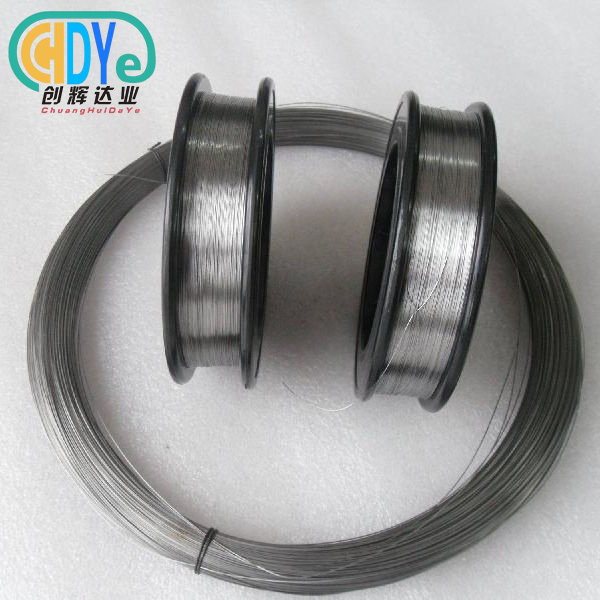

Welcome to Shaanxi Chuanghui Daye Metal Material Co., Ltd., your trusted partner for premium tantalum plates. Our tantalum plates are manufactured from dark blue-gray tantalum metal with exceptional purity levels exceeding 99.9%. These plates offer outstanding corrosion resistance, high-temperature stability, and remarkable durability for your most demanding applications. Whether you need materials for chemical processing, electronics, or specialized industrial equipment, our tantalum plates deliver the performance and reliability you require for successful project outcomes.

Key Features and Benefits

Our tantalum products stand out in the market due to their exceptional characteristics. You'll benefit from superior corrosion resistance that withstands harsh chemical environments below 150°C. The high melting point ensures stable performance in extreme temperature conditions. These materials are ductile yet strong, allowing for complex fabrication while maintaining structural integrity. The biocompatibility makes them perfect for medical applications, while their excellent electrical properties serve electronics industries exceptionally well.

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Ta >99.9% |

| Size | Thickness 0.5-20mm*width50-1200*Length30-2500mm |

| Type | foil strip shape are all available |

| Density | 16.65 g/cm³ |

| Tensile Strength | 200–300 MPa |

| Melting Point | 3017°C |

| Chemical Resistance | Excellent below 150°C |

| Certificate | ISO 9001:2015 |

| Condition | Annealed |

| Delivery time | Normal production time |

| Surface | Bright surface |

| Payment terms | 30%TT in advance, 70% balance before shipment |

Available Grades and Materials

We offer various tantalum grades to meet your specific requirements. Pure tantalum provides maximum corrosion resistance for chemical applications. Tantalum 2.5% tungsten alloy offers enhanced strength for corrosive environments. Our tantalum 10% tungsten variant excels in high-temperature corrosive conditions. Furnace-grade tantalum contains specialized additives that slow grain growth and extend service life in vacuum furnace applications.

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Manufacturing Process

Our manufacturing process begins with high-purity tantalum raw materials. We employ advanced melting techniques to ensure uniform composition throughout each plate. Precision rolling creates consistent thickness and surface finish. Heat treatment optimizes mechanical properties and stress relief. Quality control measures monitor every production stage to guarantee consistent material properties and dimensional accuracy.

|

|

|

|

|

|

|

|

Applications and Industries

Your projects can benefit from tantalum's versatility across multiple sectors. Chemical processing equipment relies on its corrosion resistance for handling aggressive chemicals. Electronics and semiconductor industries utilize its excellent electrical properties for capacitors and circuit components. Medical applications leverage its biocompatibility for implants and surgical instruments. Defense applications appreciate its durability and reliability in extreme conditions.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to meet your precision requirements. Thickness tolerance typically ranges from ±0.05mm to ±0.1mm depending on plate thickness. Width and length tolerances are held to ±1.0mm for standard dimensions. Surface finish options include mill finish, polished, or custom treatments. Custom dimensions are available to match your specific application needs.

Product Features in Detail

The exceptional properties of our materials make them ideal for demanding applications. Corrosion resistance remains stable even in acidic environments, with only hydrofluoric acid and fluoride-containing solutions causing significant attack. High-temperature stability maintains structural integrity at elevated temperatures. Excellent formability allows complex shaping without cracking or failure. Chemical inertness prevents contamination in sensitive processes.

Quality Assurance and Testing

Every batch undergoes comprehensive testing to ensure consistent quality. Chemical composition analysis verifies purity levels meet specifications. Mechanical property testing confirms tensile strength and ductility requirements. Dimensional inspection ensures all tolerances are met. Surface quality examination identifies any defects before shipment. Certificates of compliance accompany every order.

|

|

|

OEM & Customization Services

We understand that your applications may require specific modifications. Our experienced team can customize dimensions, surface treatments, and mechanical properties to match your requirements. Special packaging options are available for sensitive applications. Technical support helps optimize material selection for your specific use case.

Packaging and Shipping

Your orders receive careful packaging to prevent damage during transit. Protective wrapping prevents surface contamination and scratches. Sturdy crating ensures safe handling for larger shipments. We coordinate with reliable shipping partners to ensure timely delivery. Tracking information keeps you informed throughout the shipping process.

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, we bring unmatched expertise to every project. Our location in China's "Titanium Capital" provides access to premium raw materials and specialized manufacturing capabilities. We've successfully served customers in more than 50 countries worldwide. Our commitment to quality, competitive pricing, and reliable delivery makes us your ideal partner.

|

|

|

|

|

|

FAQs

Q: What makes tantalum suitable for chemical applications?

A: Tantalum's exceptional corrosion resistance allows it to withstand most acids and chemicals below 150°C, making it ideal for chemical processing equipment.

Q: Can you provide custom dimensions?

A: Yes, we offer customization services for thickness, width, and length to meet your specific requirements.

Q: What industries commonly use these products?

A: Primary applications include chemical processing, electronics, medical devices, and high-temperature furnace components.

Contact Us

Ready to discuss your tantalum plate requirements? Our technical team is standing by to help you select the right materials for your application. Contact us today at info@chdymetal.com to receive a detailed quotation and technical specifications. We look forward to becoming your trusted supplier for high-quality tantalum materials.

Learn about our latest products and discounts through SMS or email