- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Anode for Sodium Hypochlorite Generator

Product Introduction

The Titanium Anode for Sodium Hypochlorite Generator is a key component designed for the efficient online production of sodium hypochlorite solution. This generator system is widely used for disinfection and sterilization in municipal water treatment, swimming pools, hospitals, and industrial cleaning processes. The device enables users to produce sodium hypochlorite directly and safely on-site, ensuring continuous and cost-effective operation.

Internal Structure of the Titanium Anode Electrolytic Cell

- Anode: Titanium substrate coated with Ruthenium–Iridium Mixed Metal Oxide (MMO) for superior electrochemical performance.

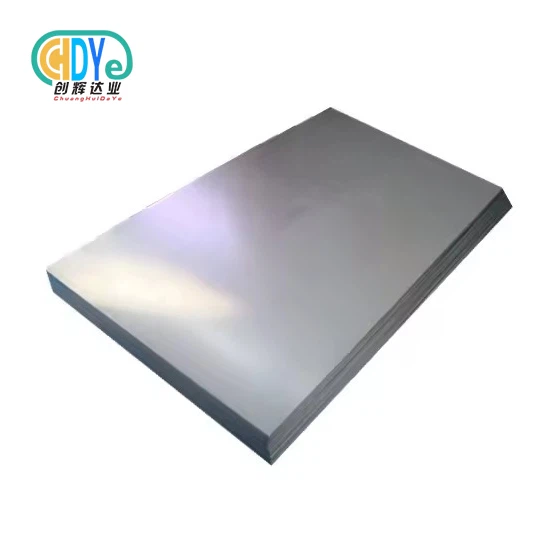

- Cathode: Made from TA1 / TA2 / GR1 / GR2 titanium plates, offering excellent corrosion resistance.

- Current Density: ≤1500 A/m²

- Design Life: 3–5 years (customizable according to application requirements)

- Shell Material: PMMA / UPVC for durability and insulation.

- Yield: 100 g–1000 g/hour (customizable output capacity)

Working Principle

- The system works by feeding diluted brine into the electrolytic cell. When DC power is applied through a silicon rectifier, electrolysis occurs, converting saltwater into sodium hypochlorite (NaClO) solution.

- For each kilogram of sodium hypochlorite produced, salt consumption is about 4.0–4.2 kg, and power consumption is approximately 4.3–4.5 kWh.

- During electrolysis, hydrogen (H₂) is generated at the cathode and chlorine (Cl₂) at the anode. The hydroxide ions produced combine with sodium ions to form sodium hydroxide (NaOH). The chlorine then reacts with sodium hydroxide to form sodium hypochlorite (NaClO).

- The electrochemical reaction can be summarized as: NaCl → Na⁺ + Cl⁻ → NaClO (Sodium Hypochlorite)

Advantages of Titanium Anode for Sodium Hypochlorite Generator

High Efficiency and Durability:

-

Constructed with a 10 mm acrylic shell and 20 mm flange seal, ensuring strong structure, easy maintenance, and superior electrolysis efficiency.

-

Produces high-concentration sodium hypochlorite with stable, corrosion-resistant, and long-lasting performance.

Customizable Design:

-

The Titanium Anode for Sodium Hypochlorite Generator can be fully customized in size, output, and lifespan to meet different operational requirements.

High-Quality Electrode Manufacturing:

-

The core electrolyzer electrode group is independently developed and produced.

-

Uses industrial-grade pure titanium substrate with multi-component precious metal oxide coatings to ensure optimal electrochemical activity and extended service life.

In summary, the Titanium Anode for Sodium Hypochlorite Generator provides a stable, efficient, and low-maintenance solution for continuous sodium hypochlorite production, ensuring consistent water disinfection and superior operational reliability.

Application Advantages

The Titanium Anode for Sodium Hypochlorite Generator is an essential electrochemical component designed for the efficient and stable production of sodium hypochlorite from seawater or brine. Its advanced mixed metal oxide (MMO) coating, typically consisting of ruthenium–iridium oxides (Ru-IrO₂), ensures long-lasting durability and high catalytic performance under harsh electrolysis conditions.

Main Advantages:

- High Electrochemical Efficiency: Ensures stable chlorine and hypochlorite generation with low energy consumption.

- Corrosion Resistance: Excellent resistance to chlorine, seawater, and alkaline environments.

- Long Service Life: Superior coating adhesion provides consistent performance and extended lifespan.

- Low Maintenance: Minimal surface passivation and easy cleaning, reducing downtime.

- Stable Output: Ensures consistent sodium hypochlorite concentration even under variable salinity and temperature conditions.

- Eco-Friendly: Supports on-site sodium hypochlorite production without handling hazardous chlorine gas.

Applications include water treatment plants, marine sanitation systems, swimming pool chlorination, industrial disinfection systems, and municipal water supply projects.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Each Titanium Anode for Sodium Hypochlorite Generator is produced through a precise multi-stage process to guarantee performance and reliability:

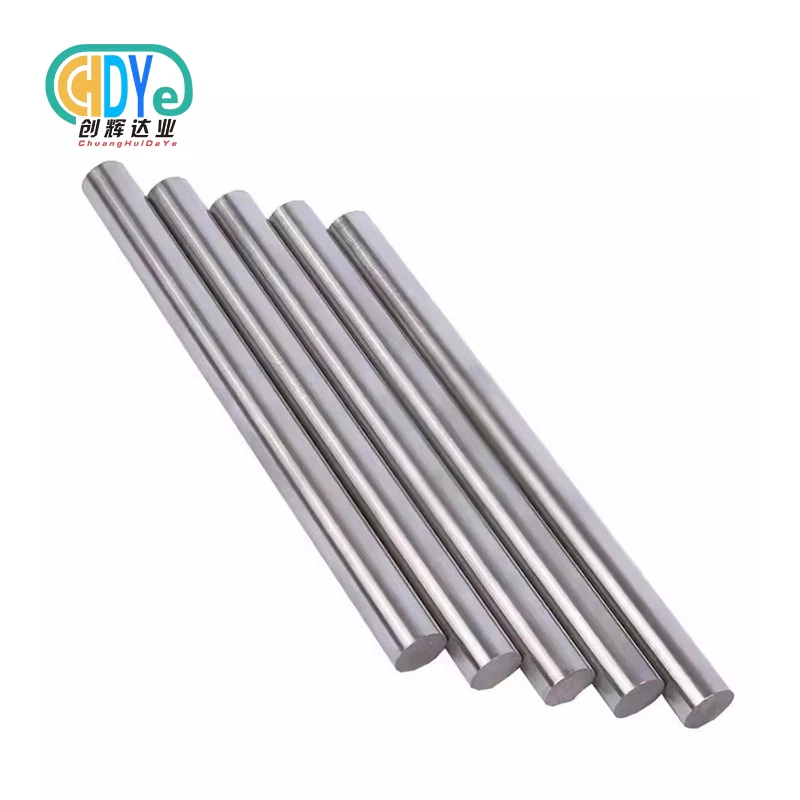

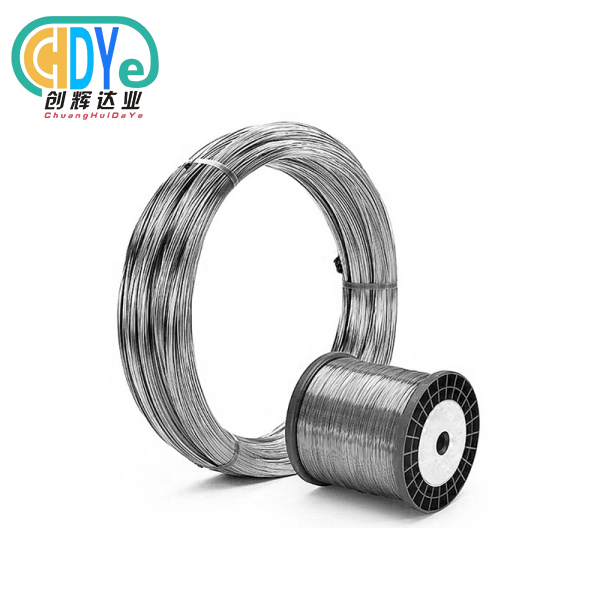

- Titanium Substrate Selection – High-purity titanium (Grade 1 or Grade 2) is selected for its excellent formability and conductivity.

- Surface Pretreatment – Degreasing, acid etching, and cleaning to remove oxide layers and ensure coating adhesion.

- MMO Coating Application – Multiple layers of Ru-IrO₂ or Ti/IrO₂ coating are applied using a thermal decomposition technique.

- High-Temperature Sintering – Each layer is sintered to achieve strong bonding and stable electrochemical activity.

- Performance Testing – Coating thickness, adhesion, and electrochemical performance are tested before shipment.

This strict manufacturing control ensures that each anode delivers consistent current efficiency, uniform chlorine release, and long operational stability.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye follows the ISO 9001:2015 Quality Management System, ensuring traceable and consistent quality across all production batches.

Inspection Procedures:

- Raw Material Verification (Titanium purity ≥99.6%)

- Coating Composition Analysis (Ru-Ir ratio and oxide uniformity)

- Microscopic Surface Structure Testing

- Accelerated Life Cycle Simulation

- Coating Adhesion & Bond Strength Evaluation

- Electrochemical Performance Testing in Chloride Solution

Every anode is visually and dimensionally inspected before delivery to ensure conformance with international standards such as ASTM B338, ASTM B265, and GB/T 3623.

R&D and Customization

Our dedicated R&D team continuously improves anode coatings, substrate materials, and production techniques. We offer customized technical solutions to meet specific customer requirements.

Customization Options:

- Substrate Grade: Gr1, Gr2, or other titanium alloys

- Coating System: Ru-IrO₂, Pt, or Ir-TaO₂ depending on use conditions

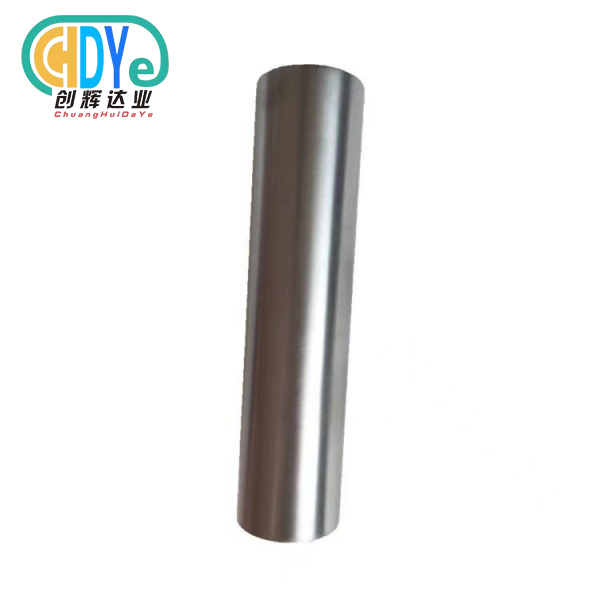

- Anode Form: Mesh, plate, tubular, or wire

- Size and Shape: Tailored to fit various generator designs

- Current Density and Life Expectancy Optimization

Our R&D focus includes enhanced coating adhesion, longer service life, and improved energy efficiency to support global clients in water treatment and electrochemical industries.

Packaging & Global Logistics

Every Titanium Anode for Sodium Hypochlorite Generator is packed to ensure safety and integrity during international transportation.

Packaging Details:

- Vacuum-sealed or anti-rust wrapping

- Foam padding for surface protection

- Export-grade plywood or wooden boxes

- Clear labeling with batch number, size, and coating type

Logistics:

We cooperate with reliable global freight partners to provide fast air, sea, and land delivery. Standard lead time is 7–10 working days, with global coverage including Europe, North America, the Middle East, and Southeast Asia.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers complete OEM and ODM services for sodium hypochlorite generator manufacturers and engineering companies.

OEM Service Scope:

- Custom size and coating formulation

- Branding and logo engraving

- Engineering design support for electrolytic systems

- Technical data and test reports upon request

- Sample testing and small-batch production available

We focus on cost-effective customization, strict confidentiality, and long-term partnership development with global clients.

Inspection Process

To ensure every anode meets performance requirements, our inspection covers:

- Dimensional Verification – Thickness, mesh aperture, and tolerance checks.

- Coating Uniformity Testing – Ensures even deposition and catalytic consistency.

- Adhesion Strength Testing – Assesses coating durability under mechanical stress.

- Electrochemical Efficiency Test – Evaluates current density and chlorine yield rate.

- Final Packaging Audit – Confirms labeling, batch traceability, and protective sealing.

Why Choose Us

- 30+ Years of Industry Expertise – Deep experience in titanium and rare metal processing.

- ISO 9001:2015 Certified Manufacturer – Complete quality traceability.

- Advanced Equipment – Electron beam furnaces, rolling, and precision machining lines.

- Global Export to 50+ Countries – Proven international logistics and after-sales support.

- 7-Day Fast Delivery – Short production cycle and ready stock.

- Customized Engineering Support – Tailored design for sodium hypochlorite systems.

Shaanxi Chuanghui Daye is your trusted supplier of high-performance titanium anodes for sustainable water treatment and chlorination applications.

|

|

|

|

|

|

FAQs

Q1: What coating types are available for sodium hypochlorite anodes?

A1: We primarily offer Ru-IrO₂ coatings for sodium hypochlorite generation, but Pt or Ir-TaO₂ coatings can be customized based on your process requirements.

Q2: What is the typical lifespan of the titanium anode?

A2: Service life varies from 3 to 10 years depending on current density, salinity, and coating type.

Q3: Can you supply complete sodium hypochlorite generator assemblies?

A3: Yes, we can provide anodes with mounting frames, connectors, and compatible components upon request.

Q4: How do you ensure coating adhesion and uniformity?

A4: Each anode undergoes multi-layer sintering and microscopic inspection to ensure strong coating adhesion and uniform catalytic activity.

Q5: What industries commonly use your sodium hypochlorite anodes?

A5: Our anodes are widely used in municipal water treatment, ship ballast water systems, swimming pool chlorination, and seawater sterilization equipment.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email