- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

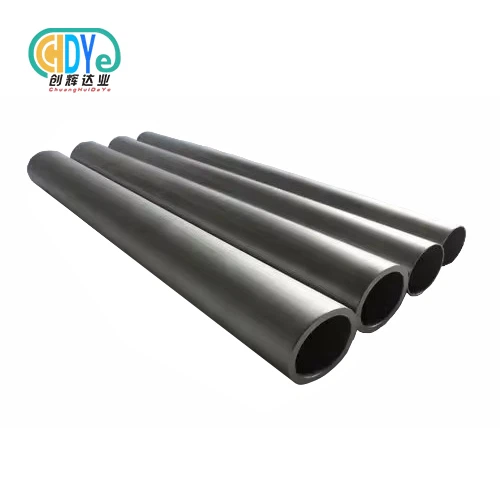

tantalum targets

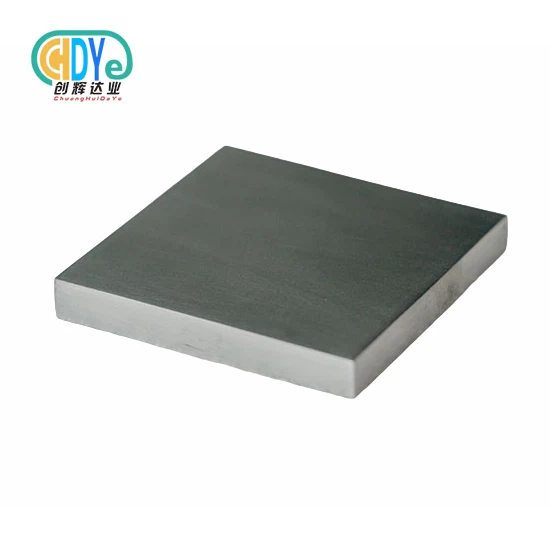

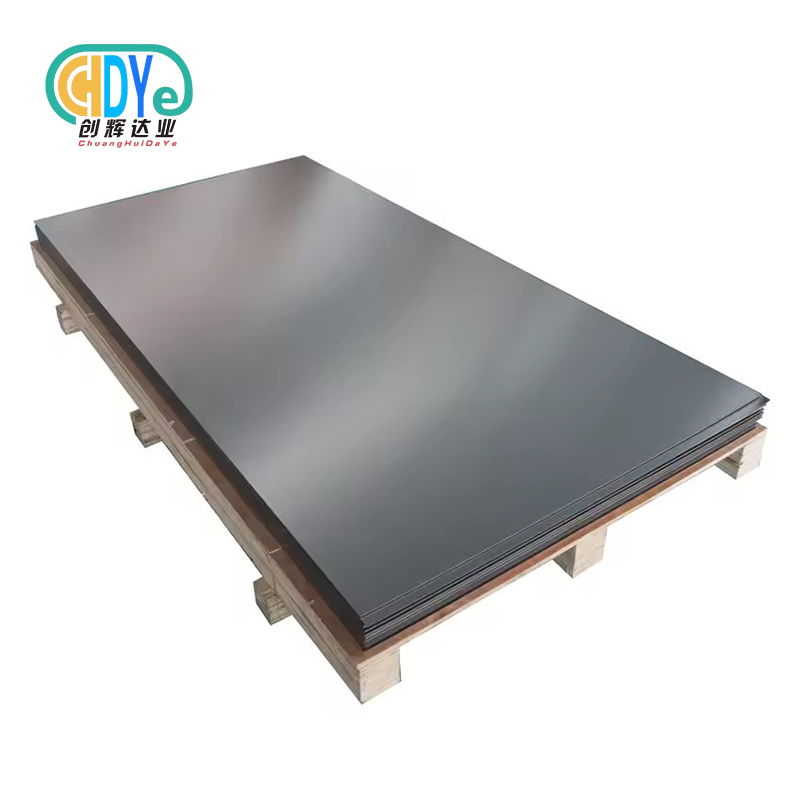

size: customized

Condition: Vacuum Annealed

Surface: Alkaline wash surface / machined

Processing technic: CNC Milling Machinery

Product introduction

tantalum targets deliver exceptional performance with 99.9% purity and ≥99.8% theoretical density. These premium materials ensure uniform deposition and consistent results for your critical applications. With over 30 years of experience in the rare metal industry, we provide reliable tantalum targets that meet the demanding requirements of semiconductor, display technology, and optical coating industries. Our materials feature superior hardness of 120–140 HV and maintain strict tolerances for professional-grade applications.

Key Features and Benefits

Our tantalum sputtering materials offer outstanding corrosion resistance and thermal stability. You get consistent performance with low vapor pressure characteristics that ensure reliable coating processes. The high melting point of 2980°C provides excellent durability in demanding environments.

These materials deliver superior dielectric properties for electronic applications. Your manufacturing processes benefit from precise thickness control and exceptional flatness specifications. The fine grain structure ensures uniform sputtering and reduced particle generation.

Technical Specifications

| Property | Specification |

|---|---|

| Purity | 99.9% minimum |

| Density | ≥99.8% theoretical (16.6 g/cm³) |

| Hardness | 120–140 HV |

| Total Metallic Impurities | ≤150 ppm |

| Thickness Range | 3–25 mm |

| Flatness | ≤0.05 mm |

| Nitrogen Content | ≤30 ppm |

| Thermal Conductivity | 57 W/m·K |

| Size | customized |

| condition | Annealed |

| Certification | ISO9001:2008 |

| Surface | Alkaline wash surface / machined |

| Processing technic | CNC Milling Machinery |

| Delivery time | normal 7-15 working days |

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Available Grades and Materials

We offer Ta-1 and Ta-2 grades to meet your specific requirements. Both grades maintain 99.95% minimum purity with excellent chemical stability. The materials undergo vacuum annealing for optimal performance characteristics.

You can choose between alkaline wash surface or machined finish options. Custom compositions are available for specialized applications requiring unique properties.

Manufacturing Process

Our production begins with high-purity tantalum powder created through sodium thermal reduction. The powder undergoes cold isostatic pressing at pressures exceeding 200 MPa for superior density.

Sintering occurs in vacuum conditions greater than 10⁻² MPa at temperatures above 2400°C. This process creates ingots with 15.4 g/cm³ density and 99.99% purity. Rolling and heat treatment follow to achieve the final specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Electronic Chip Manufacturing: Essential for semiconductor integrated circuit production. Creates thin films for capacitors and resistors with precise deposition control.

Display Technology: Used in LCD and OLED manufacturing for electrode and barrier layer formation. Improves electrical performance and extends display lifespan.

Optical Coating: Enhances transmittance and reduces reflection in optical lenses and coated glass. Provides wear resistance for camera lenses and architectural glass.

Product Dimensions and Tolerances

Standard thickness ranges from 3mm to 25mm to accommodate various sputtering systems. Custom dimensions are available to match your specific equipment requirements.

Flatness tolerance maintains ≤0.05mm for improved coating accuracy. Surface roughness specifications ensure optimal sputtering performance and reduced defect rates.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Features in Detail

The fine grain structure provides uniform sputtering characteristics throughout the material life. Low gas content prevents sputtering defects and ensures consistent film quality.

Excellent thermal conductivity of 57 W/m·K stabilizes heat transfer during operation. The materials resist cracking under thermal cycling conditions common in production environments.

Quality Assurance and Testing

Every batch undergoes comprehensive testing for purity, density, and mechanical properties. Chemical analysis confirms metallic impurity levels below 150 ppm for critical applications.

Dimensional inspection ensures compliance with specified tolerances. Surface quality assessment verifies suitability for high-performance sputtering applications.

|

|

|

OEM & Customization Services

We provide complete customization services for your unique specifications. Our engineering team works with you to develop materials that meet specific performance requirements.

Custom shapes, sizes, and backing plate assemblies are available. Special alloy compositions can be developed for research and specialized manufacturing needs.

Packaging and Shipping

All materials receive protective packaging to prevent damage during transit. Vacuum-sealed packaging options maintain material cleanliness for sensitive applications.

We coordinate shipping worldwide with trusted carriers. Proper documentation ensures smooth customs clearance for international deliveries.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we benefit from three decades of rare metal expertise. Our founder's extensive industry experience ensures deep understanding of your material needs.

We serve customers in over 50 countries including the United States, Germany, South Korea, and Singapore. This global experience helps us understand diverse application requirements and quality standards.

Our competitive pricing, on-time delivery, and customer-focused service create lasting partnerships. We prioritize trust, reliability, and continuous improvement in all business relationships.

|

|

|

|

|

|

FAQs

Q: What is the typical lead time for custom dimensions?

A: Lead times vary based on specifications, typically 2-3 weeks for standard customizations.

Q: Can you provide material certificates?

A: Yes, we provide complete chemical analysis and mechanical property certificates with each shipment.

Q: What is the minimum order quantity?

A: Minimum orders depend on specifications. Contact us for specific quantity requirements.

Contact Us

Ready to discuss your tantalum requirements? Our technical team stands ready to help you select the optimal materials for your applications.

Email us at info@chdymetal.com for detailed quotations and technical support. We provide prompt responses and comprehensive material recommendations based on your specific needs.

Learn about our latest products and discounts through SMS or email