- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pure Tungsten Rod

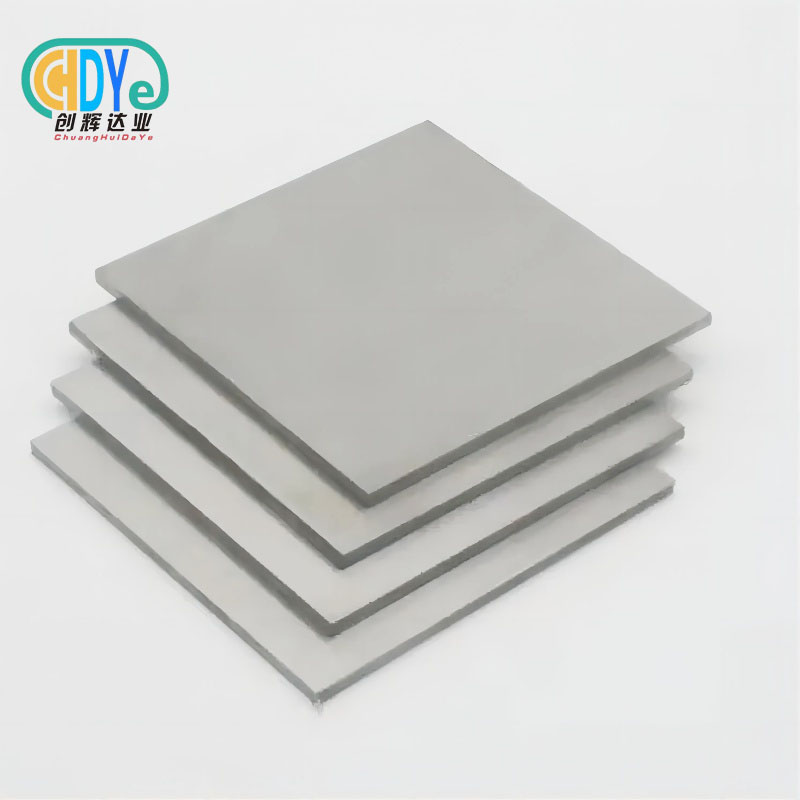

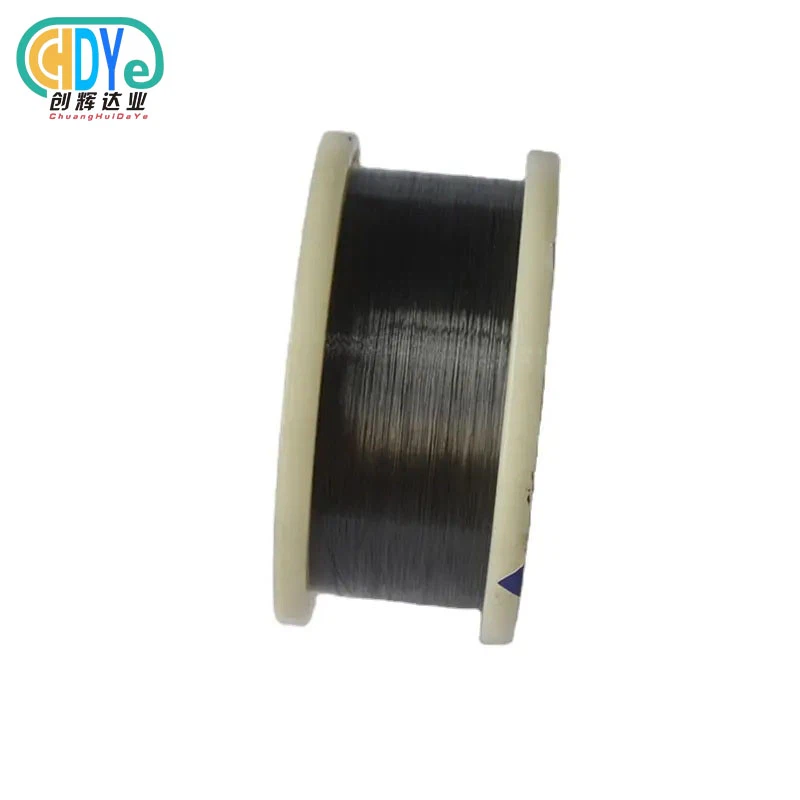

Product Introduction

The Pure Tungsten Rod offered by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is manufactured using high-purity tungsten powder and advanced powder metallurgy technology. With an impressive melting point of 3410°C and excellent high-temperature strength, it is ideal for use in demanding industrial environments such as vacuum furnaces, lighting, and semiconductor applications. The Pure Tungsten Rod demonstrates superior thermal conductivity, high density, and outstanding resistance to erosion and deformation, making it a preferred choice for high-precision machining and thermal applications. Available in polished, ground, or centerless-finished surfaces, our tungsten rods meet ASTM, ISO, and GB standards to ensure consistent performance and reliability.

Tungsten is a rare non-ferrous metal, and tungsten rods have high density, high melting point, high hardness, good electrical and thermal conductivity, as well as excellent corrosion resistance.

Specification

|

Name |

Pure tungsten rod |

|

Shape |

cylinder, round bar, rod |

|

Size |

Diameter 3-100mm* Length 200-1000mm or as your requirements |

|

Purity |

99.95% |

|

Density |

16.85-18.85g/cm3 |

|

Surface |

black, polished, sintering, forging, machining |

|

Feature |

High temperature resistance, high intensity |

|

Service |

Welcome OEM&ODM.The size and purity can be customized as requirements. |

|

Application |

Industry,electric light source, electric vacuum industry. |

|

Delivery time |

Within 15 days after get your prepayment |

|

Payment terms |

30%TT in advance, 70% balance before shipment |

Chemical composition

|

Grade |

Tungsten content |

Contents of impurity element |

|

|

Total content |

Each content |

||

|

W1 |

99.95% Min |

0.05%max |

0.01%max |

|

W2 |

99.92% min |

0.08%max |

0.01%max |

|

WAL1,WAL2 |

99.95% min |

0.05%max |

0.01%max |

Dimension and tolerance

|

Dimension (φD * L) (mm) |

Diameter Tol. (mm) |

Length Tol. (mm) |

|

φ3~12 * 300 |

+0.20~+0.45 |

0~+5.0 |

|

φ12.5~20 * 300 |

+0.30~+0.60 |

0~+5.0 |

|

φ21~30 * 300 |

+0.50~+0.80 |

0~+5.0 |

Advantages

• Heavy Density

• Free cutting processing

• Excellent mechanical performance

• High elastic modulus

• Can effectively absorb xrays and gamma rays

(for the absorption of x rays, and gamma rays than lead high about 30% - 30%) no harm to envirnment and health.

Application

Tungsten rods have special properties such as low thermal expansion and good thermal conductivity, sufficient electrical resistance, and high elastic modulus. Therefore, tungsten rods are widely used in various fields. Such as support wires, import wires, printer needles, various electrodes and quartz furnaces, filaments, high-speed tools, automotive automation products, sputtering targets.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of the Pure Tungsten Rod involves a series of controlled steps to ensure structural integrity and high density:

- Raw Material Selection: Only high-purity tungsten powder (≥99.95%) is selected.

- Pressing & Sintering: The powder is pressed into bars and sintered under hydrogen or vacuum at temperatures above 2500°C.

- Swaging & Forging: The sintered bars are forged and swaged to achieve required mechanical strength.

- Machining & Finishing: Precision grinding, polishing, or centerless finishing ensures dimensional accuracy.

- Inspection & Packaging: Each rod undergoes multiple inspections before export-standard packaging.

Every production stage is closely monitored by experienced engineers to ensure compliance with international standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is at the heart of Shaanxi Chuanghui Daye’s manufacturing philosophy. Our Pure Tungsten Rod production strictly follows ISO 9001:2015 quality management principles.

- Raw Material Test: Each batch of tungsten powder is tested for purity and particle size distribution.

- Dimensional Accuracy: Micrometer and ultrasonic testing ensure uniform diameter and structural integrity.

- Mechanical Testing: Includes tensile strength, density measurement, and hardness verification.

- Surface Examination: Visual and microscopic inspection prevents surface defects or cracks.

- Final Review: Each rod is labeled with batch numbers and test certificates before shipment.

R&D and Customization

Shaanxi Chuanghui Daye’s R&D division focuses on continuous innovation in refractory metal processing. Our research covers microstructural optimization, high-density compaction, and improved ductility under elevated temperatures. We provide:

- Customized grades and purity levels for different industrial applications.

- Tailor-made dimensions, shapes, and finishes based on engineering drawings.

- Development of tungsten alloys for special mechanical or thermal requirements.

- Prototype production and technical support for experimental and small-lot demands.

Packaging & Global Logistics

To guarantee product safety and integrity during transport, each Pure Tungsten Rod is carefully packed following international export standards:

- Packaging: Anti-corrosion film, foam protection, and sealed wooden cases.

- Marking: Clear labeling with product name, grade, dimensions, and batch number.

- Logistics: Reliable delivery by air, sea, or land with global tracking support.

Our company has successfully exported products to more than 50 countries, ensuring timely delivery and intact arrival through well-established logistics networks.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

We offer professional OEM and ODM services to meet diverse customer needs:

- Manufacturing based on client specifications and drawings.

- Flexible order quantities, from prototype to mass production.

- Technical advice on material selection and application optimization.

- Confidential cooperation and dedicated after-sales support.

By working closely with our clients, we deliver tungsten products that exceed expectations in precision and performance.

Inspection Process

Each Pure Tungsten Rod undergoes a systematic inspection process:

- Visual Check: Detects surface irregularities or deformation.

- Dimensional Measurement: Ensures tolerance within ±0.02 mm.

- Ultrasonic Testing: Confirms internal soundness without voids.

- Hardness and Density Test: Verifies material consistency and compaction level.

- Final Quality Audit: Confirms compliance with ASTM B777 and GB/T 4189 standards before packaging.

Our strict inspection protocol guarantees stable and repeatable product quality.

Why Choose Us

- 30+ Years of Industry Expertise: Deep understanding of tungsten and rare metal manufacturing.

- Comprehensive Product Range: Tungsten, molybdenum, tantalum, niobium, and titanium products.

- Advanced Equipment: Electron beam furnaces, forging and rolling lines, CNC machining centers.

- Global Reach: Export to 50+ countries across North America, Europe, and Asia.

- Full Quality Guarantee: ISO 9001:2015 certification and complete traceability system.

- Fast Delivery: Standard sizes available with 7-day dispatch for urgent orders.

- Professional Service: Customized technical solutions and 24-hour online support.

Choosing Shaanxi Chuanghui Daye means choosing reliability, quality, and precision.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your tungsten rod?

A1: Our Pure Tungsten Rod is produced with a minimum purity of 99.95%, ensuring superior performance in high-temperature and vacuum applications.

Q2: What surface finishes are available?

A2: We provide ground, polished, and centerless-finished surfaces according to customer requirements.

Q3: Can you produce rods in custom sizes?

A3: Yes, customized diameters (Ø1–100 mm) and lengths (100–2000 mm) are available upon request.

Q4: What standards do your products comply with?

A4: Our tungsten rods conform to ASTM B760, GB/T 4189, and ISO 9001:2015 standards.

Q5: How do you ensure safe delivery of tungsten rods?

A5: All products are packed in anti-corrosion film and foam-protected wooden boxes to ensure safe transportation to your destination.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email