- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

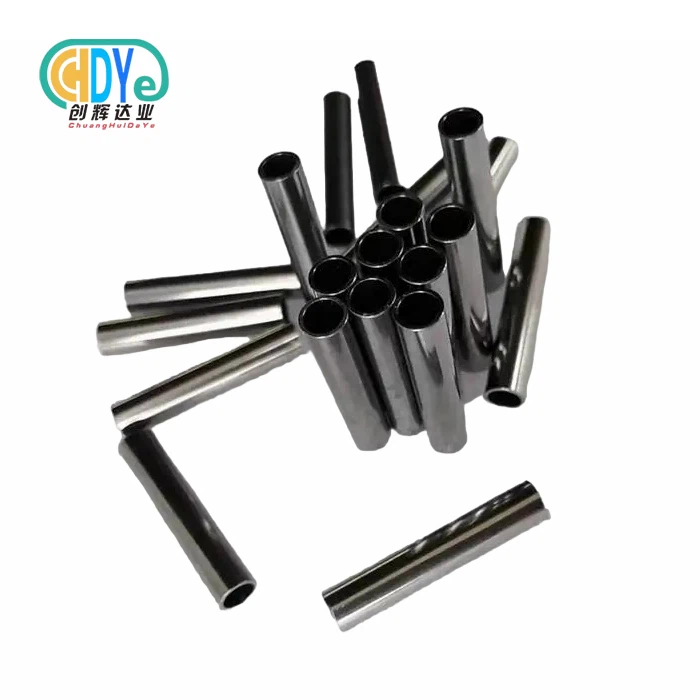

Tantalum Alloy Tube

2.Applications: Used in heat exchange tubes of heat exchangers.

3.Standard : As per ASTM B521-98

Product Introduction

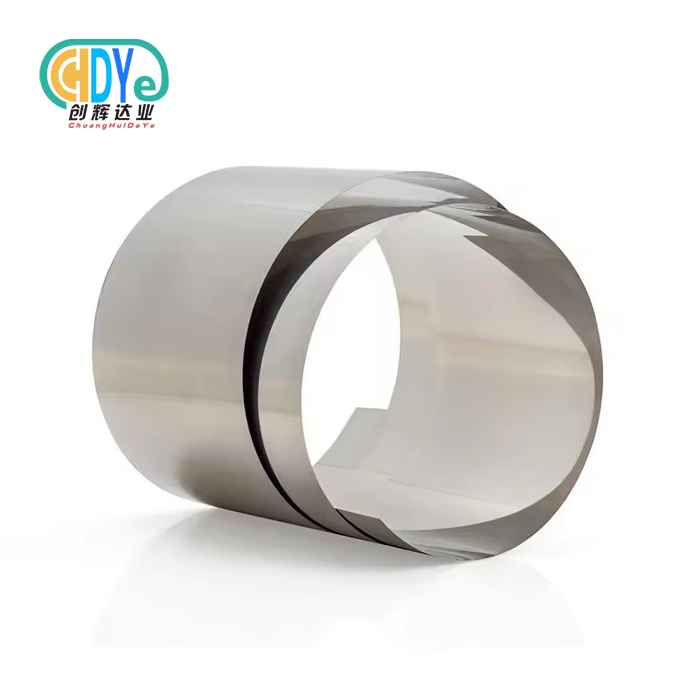

Chdymetal provide tantalum alloy tubes in R05200, R05400, R05252(Ta-2.5W), and R05255(Ta-10W) materials, the product surface is smooth and scratch-free, which meets the ASTM B521 standard.

Specification: Diameter φ2.0-100mm, Thickness 0.2-5.0mm,. Length 100mm-12000mm.

Applications: Used in heat exchange tubes of heat exchangers.

Standard : As per ASTM B521-98

Tantalum alloy tube Grade and Mechanical Properties (Annealed)

|

Grade |

Tensile Strength min, lb/in2 (MPa) |

Yield Strength min, lb/in2 (MPa) |

Elongation, min%, 1 inch gauge length |

|

R05200/R05400 |

30000(207) |

20000(138) |

25 |

|

R05252 |

40000(276) |

28000(193) |

20 |

|

R05255 |

70000(481) |

60000(414) |

15 |

|

R05240 |

40000(276) |

28000(193) |

20 |

Application Advantages

• Chemical reaction vessels and heat exchangers, pipes, condensers, bayonet heaters, helical coils, U-tubes.

• Thermocouple and its protection tube.

• Liquid metal containers and pipes, etc.

• Tantalum tube for cutting the tantalum ring for jewelry field.

Other Products of Tantalum Alloy Tube

• Tantalum Tubes

• ASTM B521 Tantalum Tube

• Tantalum Tungsten Alloy Tubes

• Tantalum UNS R05400 Tubing Manufacturer

• Tantalum capillary tube

• Tantalum UNS R05200 Tubes

• Ta-10W Pipes Supplier

• Tantalum Alloy Tubes Exporter

• pure tantalum tube

• Tantalum hollow tube

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye Metal Material Co., Ltd. employs a fully integrated production process to ensure precision and reliability at every stage:

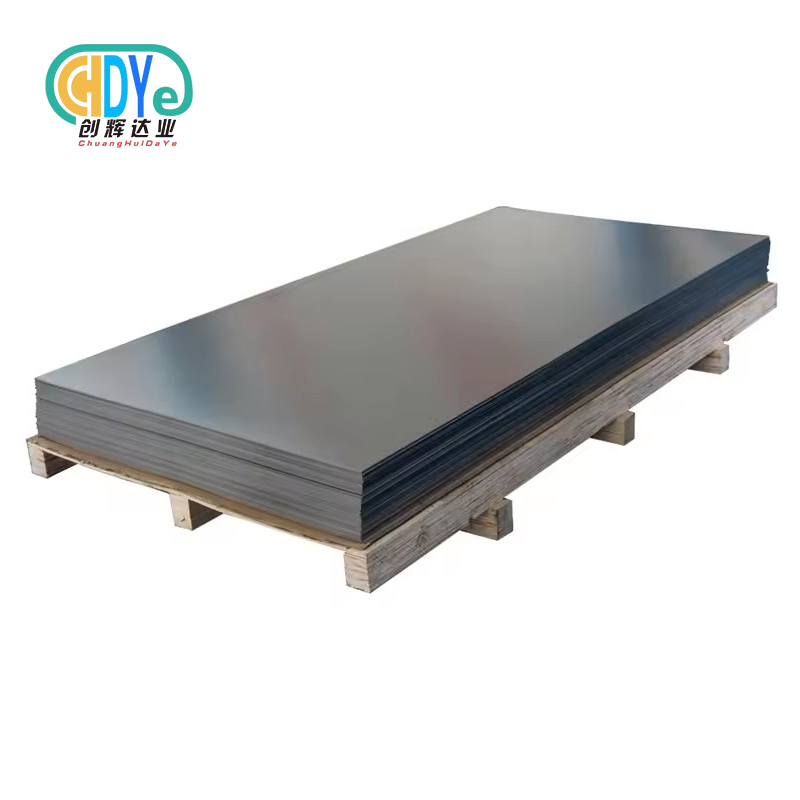

Raw Material Selection: Sourcing high-purity tantalum and alloying elements (Ta-2.5W, Ta-10W, etc.) compliant with ASTM B521 standards.

Melting & Refining: Electron beam or vacuum arc melting ensures ultra-high purity and uniform composition.

Extrusion & Rolling: Controlled deformation improves grain structure and mechanical strength.

Tube Drawing: Multi-step cold working to achieve accurate dimensions and smooth internal surfaces.

Annealing & Heat Treatment: Conducted in a high-vacuum environment to optimize ductility and stress relief.

Final Machining & Inspection: Precision cutting, surface finishing, and dimensional control.

Cleaning & Packaging: Degreasing, ultrasonic cleaning, and vacuum packaging to maintain purity before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

At Chuanghui Daye, quality assurance is integrated into every stage of production:

ISO 9001:2015 Certified Quality Management System

Raw Material Analysis: Chemical composition verified via XRF and spectrographic testing.

Dimensional Accuracy Check: Tolerances controlled according to ASTM B521 / ASTM B708 standards.

Mechanical Testing: Tensile strength, elongation, and hardness tests ensure mechanical reliability.

Non-Destructive Testing (NDT): Ultrasonic and eddy current inspection for internal flaw detection.

Surface Quality Inspection: Ensuring defect-free, mirror-finished or matte-polished surfaces.

Final Packaging Review: Ensuring proper labeling, documentation, and export readiness.

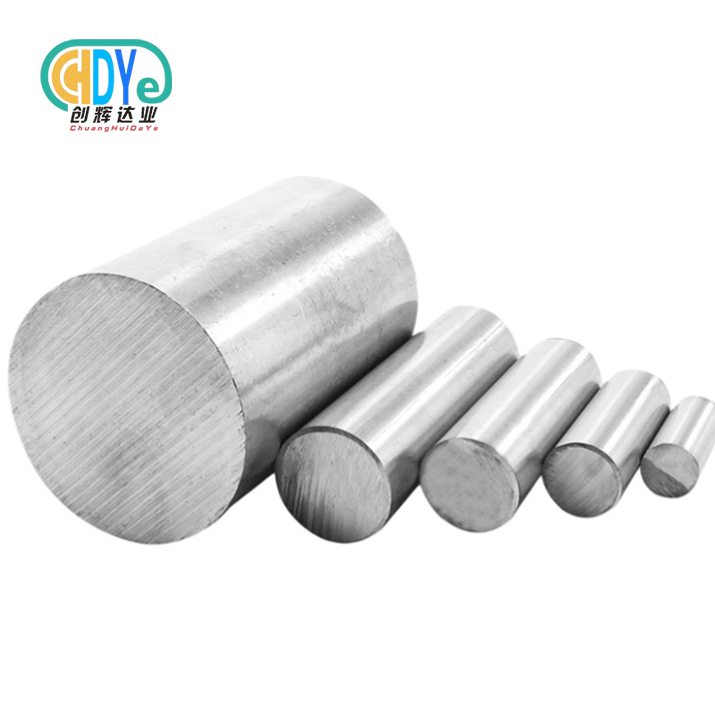

R&D and Customization

Our R&D division is driven by over 30 years of experience in rare metal innovation. We continuously improve product performance and develop custom solutions for advanced applications:

Alloy Development: Tantalum-tungsten and tantalum-niobium alloys tailored for specific corrosion or strength requirements.

Special Tube Geometries: Available in round, square, or oval cross-sections.

Precision Engineering: Ultra-thin wall tubes and small-diameter capillary tubing for semiconductor and laboratory use.

Surface Treatments: Polishing, etching, or passivation according to end-use conditions.

Collaborative R&D: Joint research projects with universities and high-tech enterprises to advance material technology.

Packaging & Global Logistics

To ensure product safety during transit, every shipment follows international export standards:

Packaging: Vacuum-sealed or anti-rust film wrapping, foam padding, and strong wooden crates.

Labeling: Each package is clearly marked with product specifications, batch number, and quality certificates.

Transport Options:

Air freight for urgent deliveries (within 7 days)

Sea freight for bulk shipments

Door-to-door express service available worldwide

Destination Markets: United States, Germany, France, Mexico, South Korea, Singapore, and more than 50 countries globally.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers complete OEM and ODM services for international buyers:

Custom grades (Ta, Ta-2.5W, Ta-10W, Ta-Nb alloys)

Tailored dimensions and tolerances

Prototype & small-batch production support

Engineering design and technical drawings accepted

One-on-one technical consultation

Competitive pricing with consistent supply chain assurance

Inspection Process

Every Tantalum Alloy Tube undergoes a rigorous inspection protocol before shipment:

Material Identification – Verification by spectrometer analysis

Dimensional Verification – Measurement of OD, ID, wall thickness

Mechanical Property Testing – Tensile and yield strength

Surface Quality Review – Visual and microscopic inspection

Ultrasonic / Eddy Current Test – NDT for internal consistency

Final Approval – Third-party inspection available upon request

Certificate Issuance – Mill test report (MTC), EN 10204 3.1 certification included

Why Choose Us

30+ Years Industry Expertise in rare and refractory metals

Comprehensive Production Capability from melting to precision machining

ISO 9001:2015 Certified Quality Management

Global Market Reach: Exporting to 50+ countries

7-Day Fast Delivery and reliable logistics support

Experienced Engineering Team providing technical guidance and OEM solutions

100% Quality Guarantee with strict inspection and traceability

|

|

|

|

|

|

FAQs

Q1: What grades of tantalum alloy tubes do you supply?

A1: We offer Ta, Ta-2.5W, Ta-10W, and Ta-Nb alloys, in compliance with ASTM B521 and ASTM B708 standards.

Q2: What is the maximum tube length and diameter you can produce?

A2: Outer diameters range from 3mm to 120mm, with lengths up to 3000mm or customized per request.

Q3: Can you provide small quantity or prototype orders?

A3: Yes, we support prototype, sample, and small-batch production for R&D and testing purposes.

Q4: What surface finishes are available?

A4: Polished, bright, matte, or pickled finishes are available based on application needs.

Q5: How long does delivery take?

A5: Standard orders are shipped within 7–15 working days, depending on quantity and customization.

Q6: Do you provide third-party inspection and test reports?

A6: Yes, SGS, BV, and other third-party inspections can be arranged. Mill test certificates are included with each batch.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email