- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

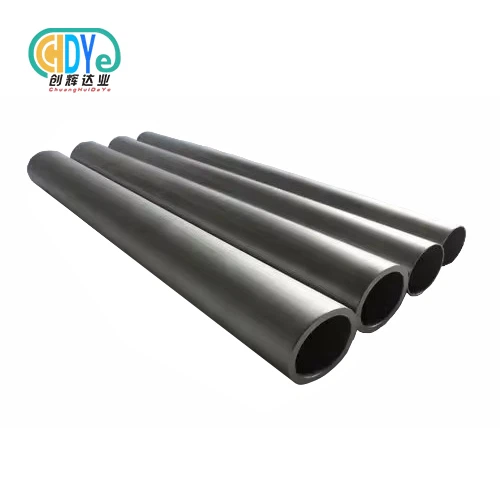

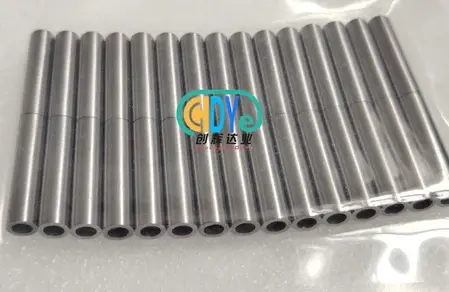

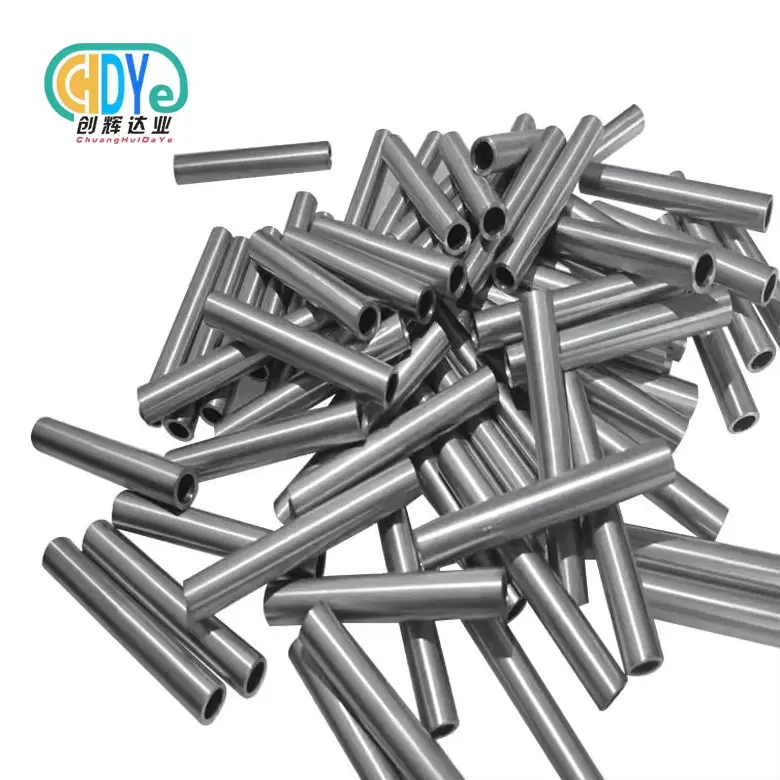

Tantalum Capillary Tube

2.Standard: ASTM B 521-98

Product Introduction

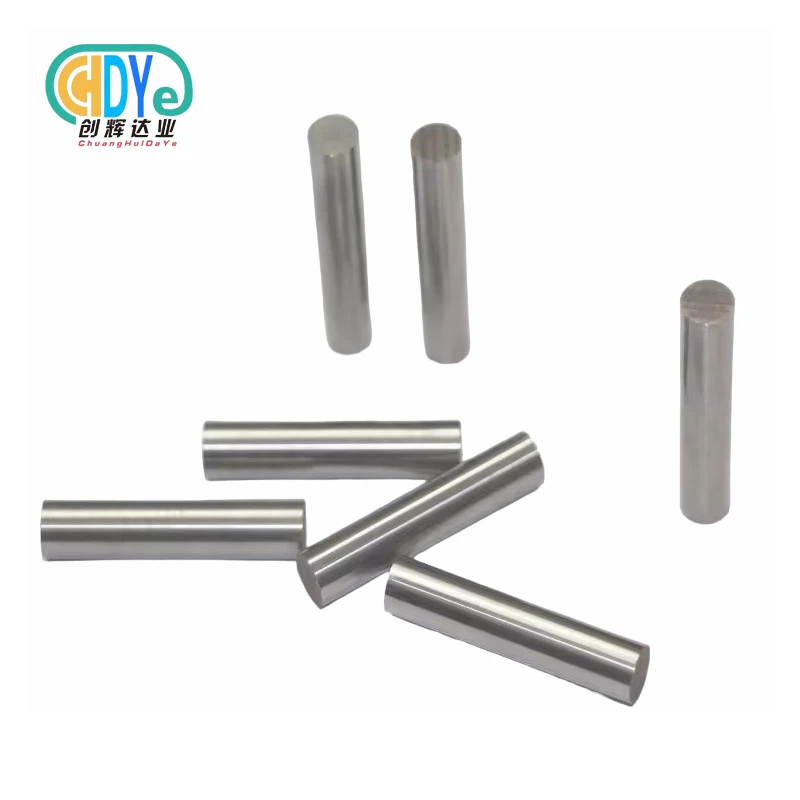

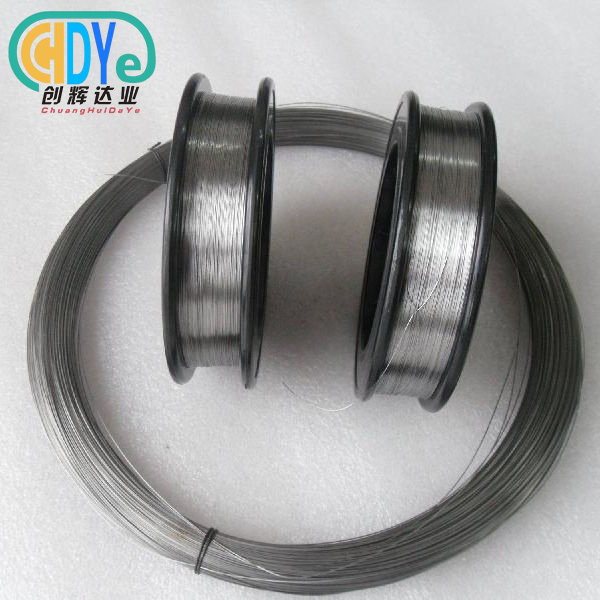

Tantalum capillary tube melting point is 2996℃ and the density is 16.68g/cm. Due to its high melting point, corrosion resistance and good cold processing performance, tantalum tube and tantalum-tungsten alloy tube are widely used in chemical industry, high temperature technology field and atomic energy industry. Tantalum capillary pipe are mainly used to manufacture reaction vessels and heat exchangers, pipelines, condensers, bayonet heaters, spiral coils, U-shaped tubes, thermocouples and their protection tubes, liquid metal containers and in chemical processes pipelines.

Specifications and paremeter

1. Grade: R05200,Ta1, R05252(Ta-2.5W),R05255(Ta-10W)

2. Size : OD:0.8-3mm min. Wall Thickness: 0.015-0.5mm Length: as your request

3. Standard: ASTM B 521-98

4. Color: Silvery gray

5. Supply condition: Cold rolled, Hot rolled, Extruded

6. Product Feature : High melting point, High-density, high temperature oxidation resistance, long service life, resistance to corrosion.

Tantalum Capillary Tubes Feature:

* Good ductility

* Good plasticity

* Excellent acid-resistance

* High melting point, high boiling point

* Very small coefficients of thermal expansion

* Good capability of absorbing and releasing hydrogen

Our Products

Application Advantages

- Used in laboratory equipment.

- Used as a substitute for platinum.

- Used as the filament lead tube of the cathode insulator in an X-ray tube.

- Used in liquid tantalum electrolytic capacitors.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

At Shaanxi Chuanghui Daye Metal Material Co., Ltd., tantalum capillary tubes are produced using advanced precision forming and deep drawing techniques to ensure high dimensional accuracy and superior surface finish.

Standard Process Flow:

- Raw Material Selection: 99.95%–99.99% high-purity tantalum ingots (ASTM B365 or RO5200)

- Vacuum Melting & Refining: Electron beam or powder metallurgy refining

- Hot & Cold Working: Multi-step extrusion, drawing, and annealing

- Precision Machining: Capillary hole drilling and surface polishing

- Heat Treatment: Controlled annealing for improved ductility and structure

- Dimension Calibration: Micro-tolerance control through precision rolling

- Final Inspection & Cleaning: Ultrasonic cleaning, purity testing, and surface passivation

This strict manufacturing route ensures uniform wall thickness, high surface smoothness, and excellent microstructural consistency.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is central to every production stage. Our factory is ISO 9001:2015 certified, ensuring consistency, reliability, and traceability.

Inspection Procedures Include:

- Chemical composition analysis (ICP-OES, GDMS)

- Dimensional accuracy testing (laser micrometer)

- Ultrasonic & eddy current testing for internal defects

- Surface quality inspection under optical microscopy

- Mechanical property testing (tensile strength, elongation)

- Hydrogen, oxygen, and nitrogen content detection

Every batch of tantalum capillary tubes comes with a full mill test certificate (MTC) according to ASTM B521 or customer-specified standards.

R&D and Customization

Our R&D team continuously works to optimize micro-tube forming processes and develop tailored solutions for complex applications. With over 30 years of expertise in refractory metal processing, Chuanghui Daye offers:

- Ultra-thin wall customization (as low as 0.05 mm)

- Precision micro-tubes for semiconductor and optical instruments

- Alloy modifications (Ta-2.5W, Ta-10W, TaNb series)

- Custom chemical surface treatments or oxide coatings

We also provide engineering consultation and prototype development for specialized applications.

Packaging & Global Logistics

To ensure product safety and purity during transportation, each tantalum capillary tube is carefully packed in anti-static film, vacuum-sealed, and cushioned with foam.

Packaging Options:

- Vacuum-sealed polyethylene bags

- Anti-rust or oil-coated paper layers

- Export-grade plywood cases with foam protection

Global Shipping:

- Air Freight: Fast international delivery (DHL, FedEx, UPS)

- Sea Freight: Cost-effective bulk shipment for industrial quantities

- Custom Documentation: MSDS, Certificate of Origin, and inspection reports

All packaging strictly complies with international export standards to guarantee integrity upon arrival.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers flexible OEM and ODM services to meet specific engineering and design requirements.

Our Custom Services Include:

- Tailor-made diameters (OD: 0.3–10 mm; ID: 0.1–9.8 mm)

- Custom tolerances and surface finishes

- Small-batch prototype fabrication

- Custom labeling and marking (batch number, grade, heat number)

- Technical documentation and after-sales support

We ensure fast production turnaround and global delivery within 7–10 working days for standard sizes.

Inspection Process

Our inspection system follows a multi-level verification protocol to ensure that each product meets the highest industrial standards:

- Incoming Material Inspection – Purity and certificate verification

- Process Monitoring – Real-time thickness and dimensional control

- Intermediary Checkpoints – Post-drawing microstructure analysis

- Final Quality Testing – Mechanical, chemical, and visual examination

- Pre-shipment Audit – Final inspection and packaging review

This end-to-end process guarantees 100% quality assurance before dispatch.

Why Choose Us

- 30+ Years of Rare Metal Expertise – Proven industrial experience in tantalum processing

- ISO 9001:2015 Certified Quality System – Ensures reliability and consistency

- Complete In-House Production – From melting to final machining

- Custom Engineering & R&D Support – Tailored solutions for every customer

- Global Reach – Products exported to over 50 countries worldwide

- Fast Delivery & After-sales Service – 7-day delivery for standard items

|

|

|

|

|

|

FAQs

Q1: What is the minimum inner diameter for your tantalum capillary tubes?

A1: We can produce tubes with an inner diameter as small as 0.1 mm, depending on wall thickness and length requirements.

Q2: Which standards do you follow for production?

A2: Our products comply with ASTM B521, ASTM B365, or customer-specified standards such as AMS or GB.

Q3: Can you supply customized lengths or cut-to-size pieces?

A3: Yes, we can cut tubes to precise lengths as per your drawing or specification.

Q4: How do you ensure purity and corrosion resistance?

A4: We use high-purity tantalum raw materials (≥99.95%) and conduct full impurity content testing before and after production.

Q5: What is your typical lead time?

A5: Standard sizes are available within 7–10 days, while custom orders typically require 2–4 weeks depending on specifications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email