- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

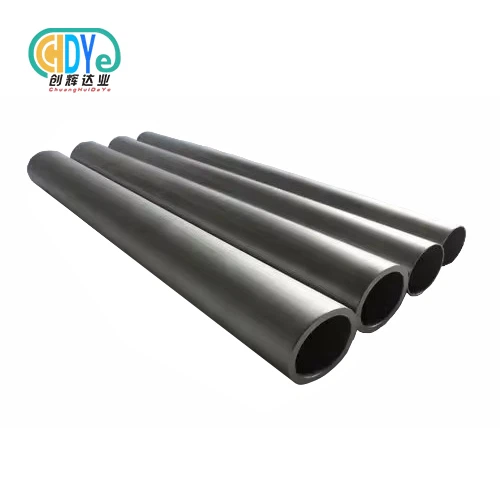

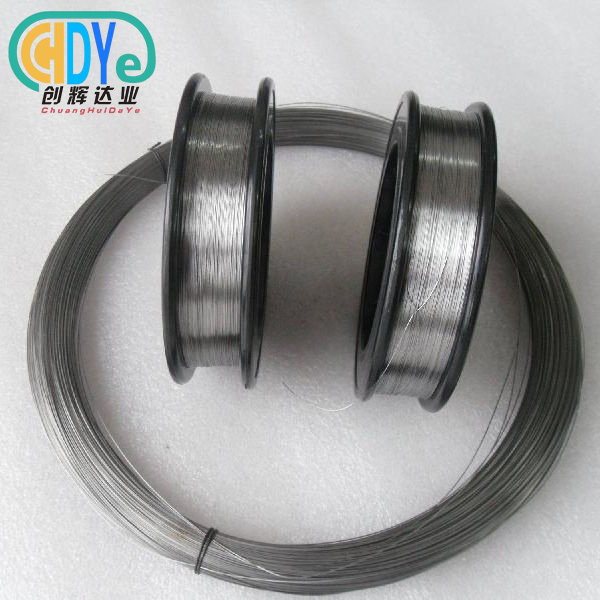

Tungsten Metal Bar

Product Introduction

The Tungsten Metal Bar from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a premium-grade refractory metal product known for its high density, exceptional hardness, and superior thermal and electrical conductivity. Manufactured with advanced powder metallurgy and precision forging technology, each Tungsten Metal Bar offers uniform microstructure, excellent mechanical properties, and long service life. Ideal for demanding industrial applications, the Tungsten Metal Bar is available in standard and custom dimensions to meet global customer requirements, ensuring reliable performance across various high-stress and high-temperature environments.

Features:

Composition: Tungsten metal bars are made from pure tungsten, which means they consist of almost entirely tungsten atoms. The purity level of tungsten in these bars can vary, but they are typically produced to high levels of purity to meet specific performance requirements.

Density: 17.5g/cm3. Tungsten has one of the highest densities of all naturally occurring elements, making tungsten metal bars exceptionally heavy for their size. This high density is desirable for various applications, such as counterweights in aerospace and medical devices.

Melting Point: Tungsten has an extremely high melting point, around 3,422 degrees Celsius (6,192 degrees Fahrenheit). This property makes tungsten metal bars suitable for use in high-temperature environments.

Application Advantages

The Tungsten Metal Bar finds extensive use across multiple industries:

- Aerospace & Defense: Counterweights, penetrators, and radiation shielding components.

- Electronics & Semiconductors: High-temperature electrodes, filaments, and vacuum devices.

- Medical Equipment: Radiation therapy devices, collimators, and imaging equipment parts.

- Metallurgy: High-temperature furnace components, molds, and dies.

- Precision Engineering: Tools and parts exposed to extreme wear and thermal stress.

Its combination of density, durability, and high-temperature stability makes it ideal for industrial and scientific applications.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

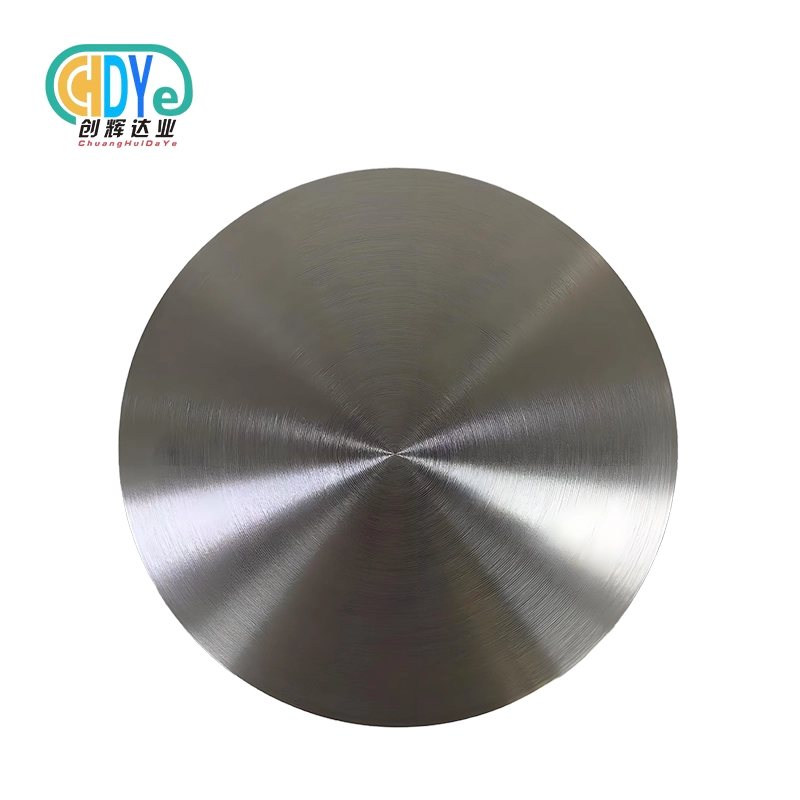

Manufacturing & Process Flow

Shaanxi Chuanghui Daye ensures that every Tungsten Metal Bar meets stringent quality standards through a controlled process:

- Raw Material Selection: High-purity tungsten powders verified for composition.

- Powder Pressing: Isostatic pressing to achieve uniform density.

- Sintering: Vacuum or hydrogen sintering to reduce porosity and enhance strength.

- Forging & Rolling: Hot forging and rolling optimize grain structure and mechanical properties.

- Machining: Precision cutting and grinding for accurate dimensions.

- Final Inspection: Comprehensive checks for structural integrity and dimensional accuracy.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Each Tungsten Metal Bar undergoes rigorous quality checks:

- Chemical Composition Analysis: Ensures high tungsten content and purity.

- Ultrasonic Testing: Detects internal defects and density uniformity.

- Mechanical Testing: Evaluates hardness, tensile strength, and elongation.

- Dimensional Verification: Confirms tolerance compliance and geometrical accuracy.

- Surface Inspection: Ensures smooth, defect-free surfaces suitable for industrial use.

ISO 9001:2015 certification guarantees reliable production and full traceability.

R&D and Customization

Our R&D team continuously improves Tungsten Metal Bar quality and application versatility:

- Development of high-density, fine-grain rods.

- Enhanced high-temperature and oxidation performance.

- Custom dimensions, grades, and alloying compositions.

- Precision machining for specialized applications in medical, aerospace, and industrial sectors.

Tailored solutions are available to meet unique customer requirements.

Packaging & Global Logistics

Every Tungsten Metal Bar is carefully packaged to prevent damage during transportation:

- Packaging: Anti-rust film, vacuum sealing, foam protection, and export-standard wooden boxes.

- Marking: Clear labeling with grade, size, and batch number.

- Transport: Reliable air, sea, and land logistics to over 50 countries worldwide.

This ensures safe, secure, and timely delivery to international clients.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye provides comprehensive OEM and ODM support for Tungsten Metal Bar:

- Production according to custom drawings and tolerance specifications.

- Small-batch prototyping and specialized manufacturing.

- Expert guidance on material selection and technical application.

- Confidential collaboration with distributors, manufacturers, and end-users.

These services ensure flexibility and precise solutions for diverse industrial needs.

Inspection Process

The inspection process for Tungsten Metal Bar includes:

- Raw Material Verification: Checking chemical composition and purity.

- In-Process Monitoring: Supervision during pressing, sintering, and forging.

- Non-Destructive Testing: Ultrasonic and density inspections.

- Dimensional Checks: Precision measurement to ensure tolerance compliance.

- Final Verification: Surface finish, labeling, and packaging inspection before shipment.

Why Choose Us

- 30+ Years Experience: Expertise in refractory metal production.

- Advanced Facilities: Electron beam furnaces, forging lines, and precision machining.

- ISO 9001:2015 Certified: Strict quality control with full traceability.

- Global Export Capability: Serving over 50 countries efficiently.

- Customizable Options: Non-standard dimensions and specialized grades.

- Fast Delivery: Standard orders processed within 7 days.

- Professional Support: Technical consultation and after-sales service worldwide.

|

|

|

|

|

|

FAQs

Q1: What purity level does your tungsten bar have?

A1: Our Tungsten Metal Bar is made from high-purity tungsten suitable for demanding applications.

Q2: Can you produce custom sizes?

A2: Yes, we offer customized Tungsten Metal Bar according to drawings and specific requirements.

Q3: Which industries use this product most?

A3: Aerospace, electronics, metallurgy, and medical equipment industries are the primary users.

Q4: What surface finishes are available?

A4: Ground, polished, and precision-machined finishes are available.

Q5: How is the product packaged for export?

A5: Each Tungsten Metal Bar is vacuum-packed, cushioned with foam, and placed in export-standard wooden cases to ensure safe transportation.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email