- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

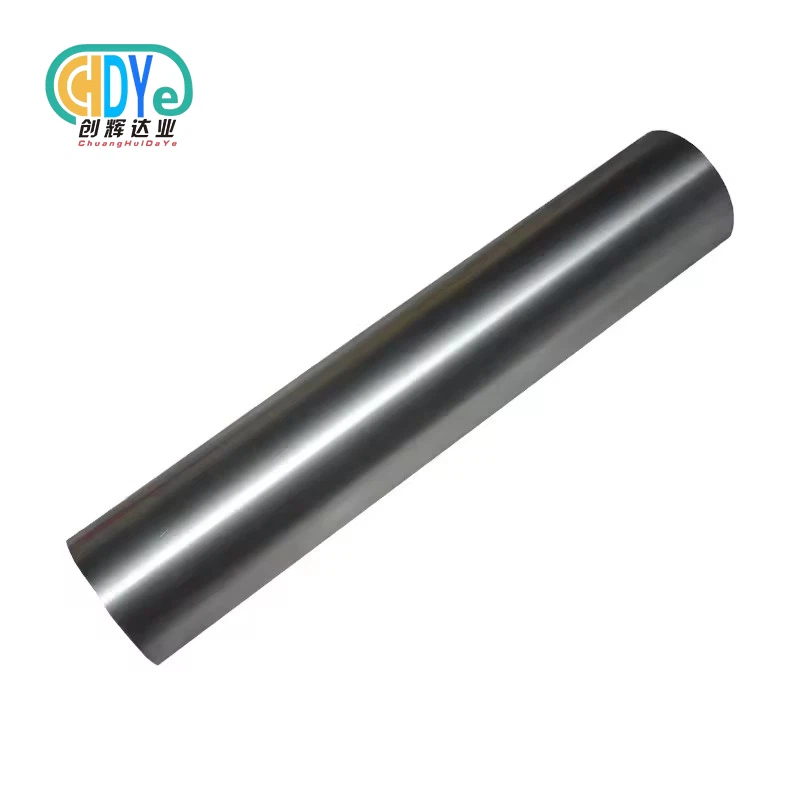

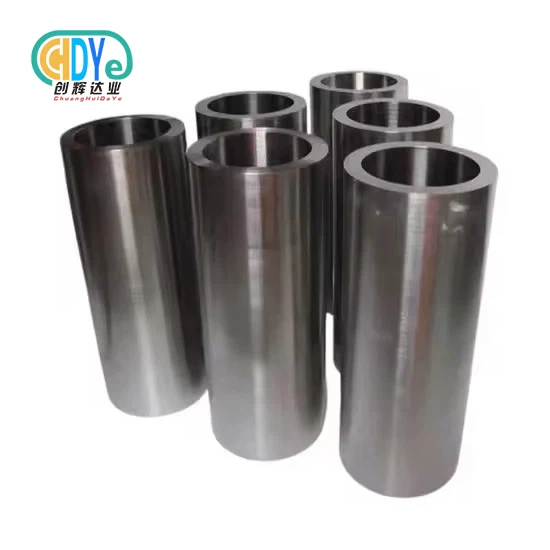

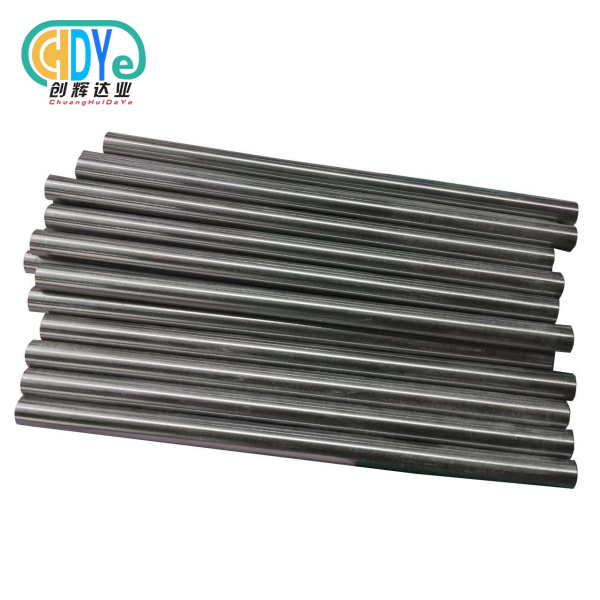

tantalum round rod

2. Diameter: 2-100mm

3. Standard: ASTM B 365

4. Delivery time: stock size will arrange within 1-3 days, normal production time about 15 working day.

Looking for a reliable tantalum round rod solution? You've come to the right place. Our premium tantalum round rod offers exceptional corrosion resistance and high-temperature performance for your demanding applications. With over 30 years of experience in rare metal manufacturing, Shaanxi Chuanghui Daye Metal Material delivers superior quality products that meet your exact specifications. Our tantalum round rod products feature 99.9% purity and excellent dimensional accuracy for critical industrial uses.

Key Features and Benefits

Our products stand out in the market due to their exceptional properties. The superior corrosion resistance makes them ideal for harsh chemical environments. You'll appreciate the excellent temperature stability that maintains strength even under extreme conditions. The biocompatibility feature ensures safe use in medical applications. These properties combined deliver outstanding performance and longevity for your projects.

Technical Specifications

|

Product name |

tantalum round rod |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ2.0—100mm*L,customized |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

|

Packing term |

Foam packing inside, wooden box outside |

|

Delivery time |

Stock size within 1-5 days normal production time about 15 days |

|

Express |

DHL,Fedex, TNT by air,by sea |

|

Payment term |

30%TT in advance,70% balance before shipment |

Chemical Composition

|

Grade |

Chemical Composition (≤%) |

||||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

||

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3.0 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Available Grades and Materials

We supply various grades to meet your specific requirements. Our standard grade offers 99.9% purity tantalum for general applications. For specialized uses, we provide high-purity grades with 99.95% tantalum content. Each grade undergoes strict quality control to ensure consistent performance. Custom alloy compositions are available upon request for unique applications.

Manufacturing Process

Our manufacturing follows proven methods developed over decades. The process starts with high-quality tantalum ingots. Through controlled forging and rolling, we achieve the desired dimensions. Cold working techniques including swaging and drawing ensure precise diameter control. Each step maintains material integrity while achieving your exact specifications.

|

|

|

|

|

|

|

|

Applications and Industries

The chemical processing industry relies on our products for reactor components and heat exchangers. Medical device manufacturers use them for implants and surgical instruments. Electronics companies incorporate them into capacitors and semiconductor equipment. Aerospace applications benefit from their high-temperature resistance and reliability.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard diameters range from 1mm to 50mm with tight tolerances. Length capabilities extend up to 1000mm for most diameters. Surface finish meets industrial standards for smooth, consistent quality. Custom dimensions are available to match your specific project requirements.

Every batch undergoes comprehensive testing before shipment. Chemical composition analysis ensures purity standards. Dimensional inspection verifies accuracy to your specifications. Surface quality checks guarantee smooth finishes. Our quality system ensures consistent results you can depend on.

OEM & Customization Services

We understand your projects may need specific solutions. Our experienced team works with you to develop custom dimensions. Special surface treatments are available when required. Packaging options can be tailored to your handling needs. Let us know your requirements and we'll provide a tailored solution.

Packaging and Shipping

Products are carefully packaged to prevent damage during transport. Protective materials shield surfaces from scratches and contamination. Labeling clearly identifies specifications and batch information. We coordinate with reliable shipping partners for timely delivery worldwide. Your order arrives ready for immediate use.

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we have access to premium raw materials. Our founder brings over 30 years of rare metal industry experience. We've successfully served customers in more than 50 countries globally. Competitive pricing combined with reliable quality sets us apart. Customer-focused service ensures your satisfaction with every order.

1.You can get the perfect material according to your requirement at the least possible price.

2.We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. we provide raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, usually stock size we can arrange 1-3 days quick delivery to save your time.

5.We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small prototype quantities and large production runs.

Q: How long is the delivery time?

A: Standard products typically ship within 2-3 weeks, custom items may require additional time.

Q: Do you provide material certificates?

A: Yes, we include complete material certificates with chemical composition and test results.

Q: Can you machine the rods to specific shapes?

A: We offer machining services to create custom configurations from standard rod stock.

Contact Us

Ready to discuss your project requirements? Our technical team is here to help you select the right material and specifications. We provide detailed quotations and technical support throughout your project. Whether you need standard sizes or custom solutions, we're committed to delivering excellent results.

Contact us today to get started on your order.

E-mail: info@chdymetal.com

Mob./what'sapp: +86 18049386902

Learn about our latest products and discounts through SMS or email