- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

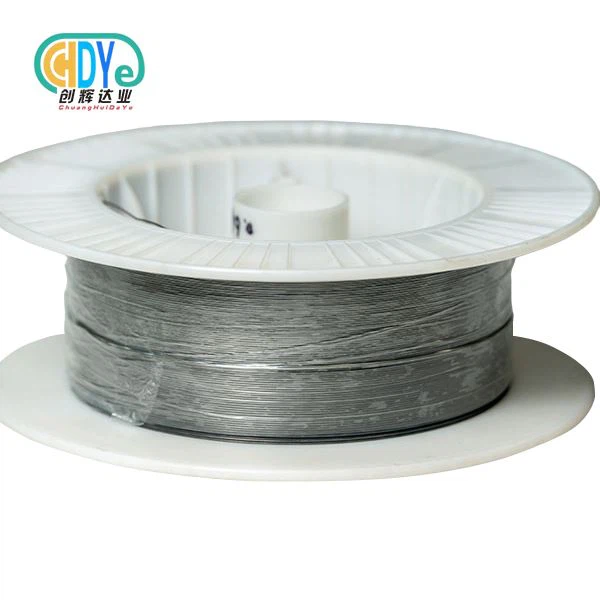

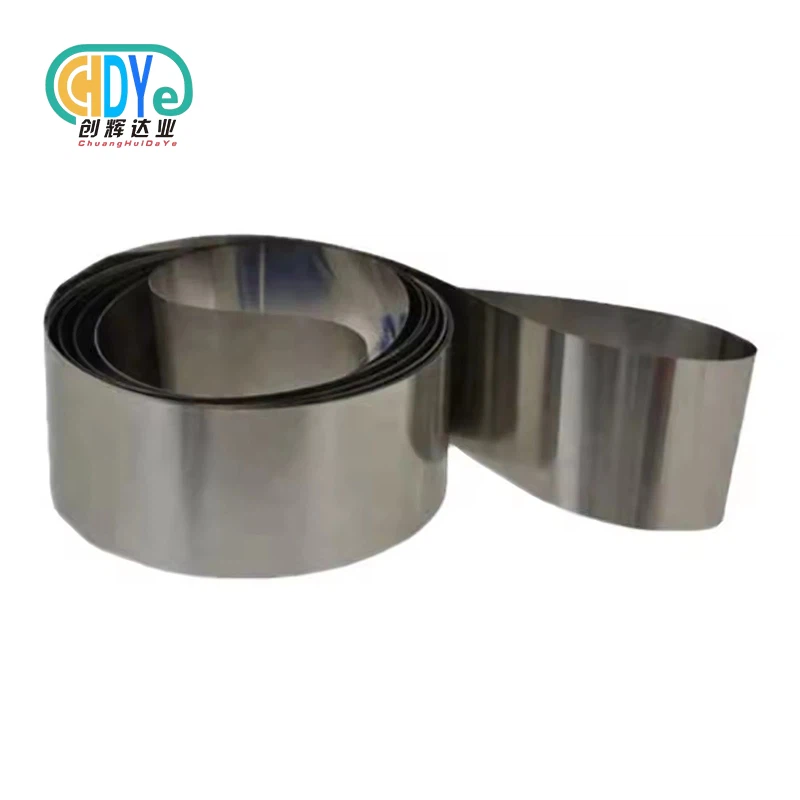

Tantalum R05200 wires

2. Diameter: 0.1–5 mm

3. Tensile strength: 200–300 MPa

4. Density: 16.65 g/cm³

5. Corrosion resistant

6. Applications: Chemical, electronics

7. Elongation: 10–20%

Looking for reliable tantalum R05200 wires for your specialized applications? You've come to the right place. Our high-grade tantalum wires deliver exceptional performance in the most demanding environments. With superior corrosion resistance and excellent electrical conductivity, these wires meet strict industry standards. Whether you need them for chemical processing, electronics, or medical devices, our tantalum R05200 wires provide the reliability you can trust. Our experienced team ensures every wire meets your exact specifications with consistent quality you can depend on.

Key Features and Benefits

Our tantalum wires offer outstanding properties that make them ideal for critical applications. The excellent corrosion resistance ensures long-lasting performance in harsh chemical environments. You'll appreciate the superior electrical conductivity that makes these wires perfect for electronic components.

The biocompatibility of tantalum makes it safe for medical applications. Your projects benefit from the high melting point of 2,996°C, providing stability in extreme temperatures. The ductile nature allows for easy fabrication and forming to meet your specific requirements.

Technical Specifications

|

Material |

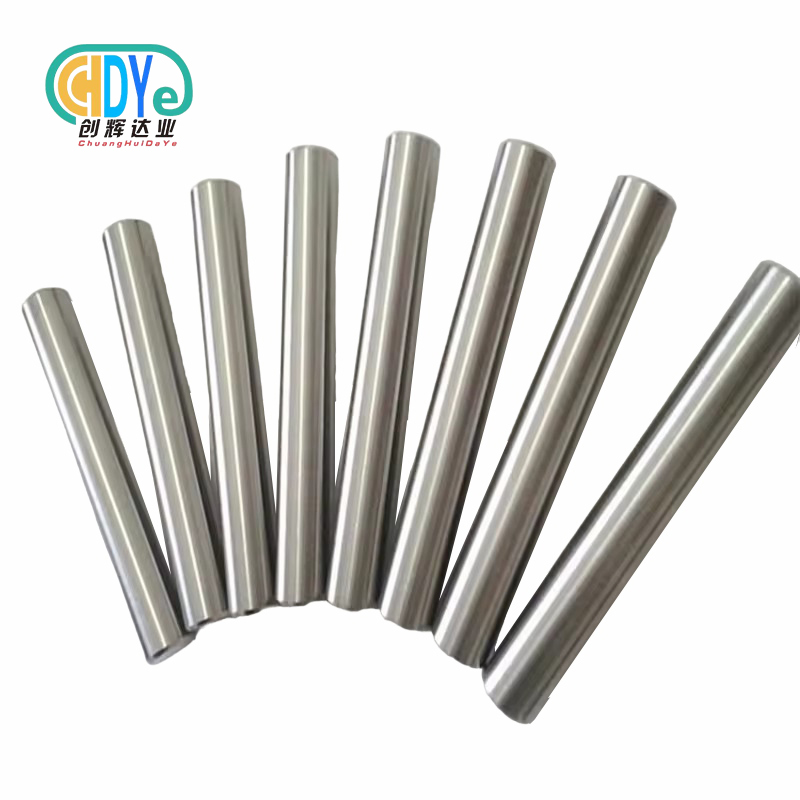

Tantalum Niobium Rod / Bar R05240 (Ta-40Nb) Pure tantalum: R05200, R05400; TantalumTungsten Rod / Bar R05252 (Ta-2.5W), R05255 (Ta-10W). |

|

Standard |

ASTM B365 |

|

Size |

0.3-3mm |

|

Service |

Customized OEM, OEM/ODM/Customized, ODM Available |

|

Packing |

Wooden box |

|

Delivery time |

Stock size will be 1-5 days,normal production time is about 15 days |

|

Payment terms |

30%TT in advance,70% balance before shipment |

|

Condition |

Annealed / unannealed |

Chemical Composition

|

Element |

R05200 (%,Max) |

R05400 (%,Max) |

|

C |

0.01 |

0.01 |

|

O |

0.015 |

0.03 |

|

N |

0.01 |

0.01 |

|

H |

0.0015 |

0.0015 |

|

Fe |

0.01 |

0.01 |

|

Mo |

0.02 |

0.02 |

|

Nb |

0.1 |

0.1 |

|

Ni |

0.01 |

0.01 |

|

Si |

0.005 |

0.005 |

|

Ti |

0.01 |

0.01 |

|

W |

0.05 |

0.05 |

Available Grades and Materials

We specialize in R05200 unalloyed tantalum produced through electron-beam furnace or vacuum-arc melt processes. This grade offers the purest form of tantalum with exceptional consistency. Our manufacturing process ensures you receive wires with uniform properties throughout every batch.

The R05200 grade provides excellent workability and surface finish. You can count on consistent mechanical properties that meet your application requirements. Each wire undergoes strict quality control to maintain our high standards.

Tantalum and Tantalum Alloy UNS Grade

R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Other tantalum alloys also can be customized.

Manufacturing Process

Our advanced manufacturing process begins with high-purity tantalum raw materials. We use electron-beam melting technology to ensure exceptional purity and consistency. The wire drawing process involves multiple stages to achieve precise dimensions and smooth surface finish.

Heat treatment at controlled temperatures optimizes the mechanical properties. Our quality control team monitors every step to ensure consistent results. The final inspection verifies dimensional accuracy and surface quality before packaging.

|

|

|

|

|

|

|

|

Applications and Industries

Tantalum wires serve critical roles across multiple industries. In chemical processing, they resist corrosion from acids and aggressive chemicals. Electronic applications benefit from excellent conductivity and reliability. Medical device manufacturers choose them for biocompatible implants and surgical instruments.

Vacuum furnace heating elements rely on tantalum's high-temperature stability. Aerospace applications demand the strength and corrosion resistance these wires provide. Research laboratories use them for specialized equipment requiring chemical inertness.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight tolerances to meet your precise requirements. Diameter tolerances typically range from ±0.005mm to ±0.02mm depending on wire size. Length can be customized from small pieces to continuous coils based on your needs.

Surface finish meets industry standards with smooth, defect-free appearance. Straightness tolerances ensure easy handling and processing. Custom dimensions are available to match your specific application requirements.

Quality Assurance and Testing

Every batch undergoes comprehensive testing to verify chemical composition and mechanical properties. We perform tensile testing to confirm strength and elongation values. Dimensional inspection ensures all specifications are met consistently.

Chemical analysis verifies purity levels and confirms grade requirements. Surface quality inspection identifies any defects before shipment. Certificate of compliance accompanies every order documenting test results.

|

|

|

OEM & Customization Services

We understand that your applications may require specific wire configurations. Our engineering team works closely with you to develop custom solutions. Whether you need special diameters, lengths, or surface treatments, we can accommodate your requirements.

Prototype quantities are available for testing and evaluation. Our flexible manufacturing capabilities allow for both small and large volume orders. Technical support helps you select the optimal wire specifications for your application.

Packaging and Shipping

Careful packaging protects your wires during shipping and storage. We use appropriate materials to prevent contamination and damage. Coiled wires are secured to prevent tangling while straight lengths are protected against bending.

Documentation includes material certificates and handling instructions. We work with reliable shipping partners to ensure timely delivery. Special packaging requirements can be accommodated based on your needs.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, we understand your quality requirements. Our location in China's "Titanium Capital" provides access to superior raw materials and manufacturing expertise. We've successfully supplied customers in more than 50 countries worldwide.

Our commitment to quality assurance and customer satisfaction sets us apart. Competitive pricing combined with reliable delivery makes us your trusted partner. Continuous improvement ensures we stay ahead of industry developments.

|

|

|

|

|

|

FAQs

Q: What makes R05200 grade special?

A: R05200 represents unalloyed tantalum with highest purity and excellent workability for most applications.

Q: Can you provide custom diameters?

A:Yes, we can manufacture wires to your specific diameter requirements within our production capabilities.

Q: What's the typical lead time?

A:Standard products typically ship within 1-2 weeks, while custom orders may require 2-3weeks.

Q: Do you provide material certificates?

A:Every shipment includes certificates documenting chemical composition and mechanical properties.

Contact Us

Ready to discuss your tantalum R05200wires requirements? Our technical team is here to help you select the right specifications for your application. Contact us today at info@chdymetal.com for detailed quotations and technical support. We look forward to becoming your trusted supplier for high-quality tantalum products.

Learn about our latest products and discounts through SMS or email