- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

20 gauge titanium wire

2. Alloy: Ti Gr2 or Gr5

3. Tensile strength: 345–895 MPa

4. Density: 4.43–4.51 g/cm³

5. Corrosion resistant: Excellent

6. Applications: Jewelry, industrial

7. Elongation: 10–25%

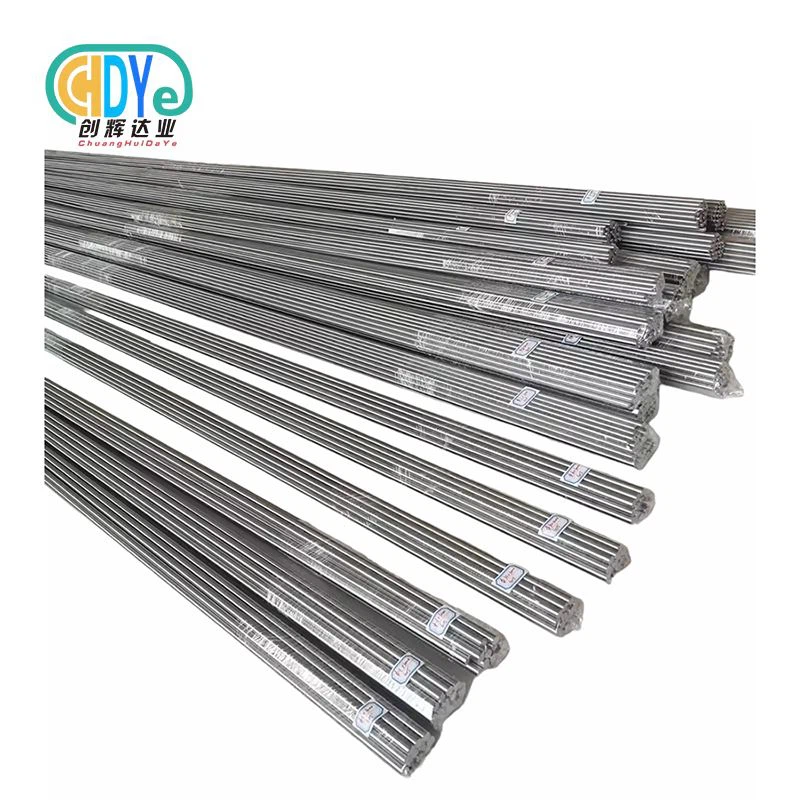

Product production

Looking for reliable 20 gauge titanium wire for your industrial or commercial projects? At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we specialize in manufacturing high-quality titanium wire with a diameter of 0.81mm. Our premium titanium wire combines exceptional strength, corrosion resistance, and lightweight properties to meet your most demanding applications. Whether you need it for welding, jewelry making, or industrial manufacturing, our 20 gauge titanium wire delivers consistent performance and reliability you can trust.

Key Features and Benefits

Our titanium wire stands out in the market due to its superior characteristics. You'll appreciate the excellent corrosion resistance that protects your projects from harsh environments. The high strength-to-weight ratio makes it perfect for applications where weight matters. Plus, the biocompatible nature ensures safe use in medical and dental applications.

The wire maintains excellent flexibility while offering outstanding durability. You can work with it easily during fabrication processes, and it will maintain its structural integrity over time. The smooth surface finish ensures consistent performance in your applications.

Technical Specifications

|

Specification |

Straight: |

|

Grade |

GR1, GR2, GR3, GR4, GR5, Ti6AL4V Eli, GR7, GR9, GR12, GR23, TC4, TC6, TC11, TC17, TC18 |

|

Application |

Chemical equipment, such as pipes, heat exchangers, evaporators, heaters, reaction kettles ect |

|

Surface |

Pickling polished |

|

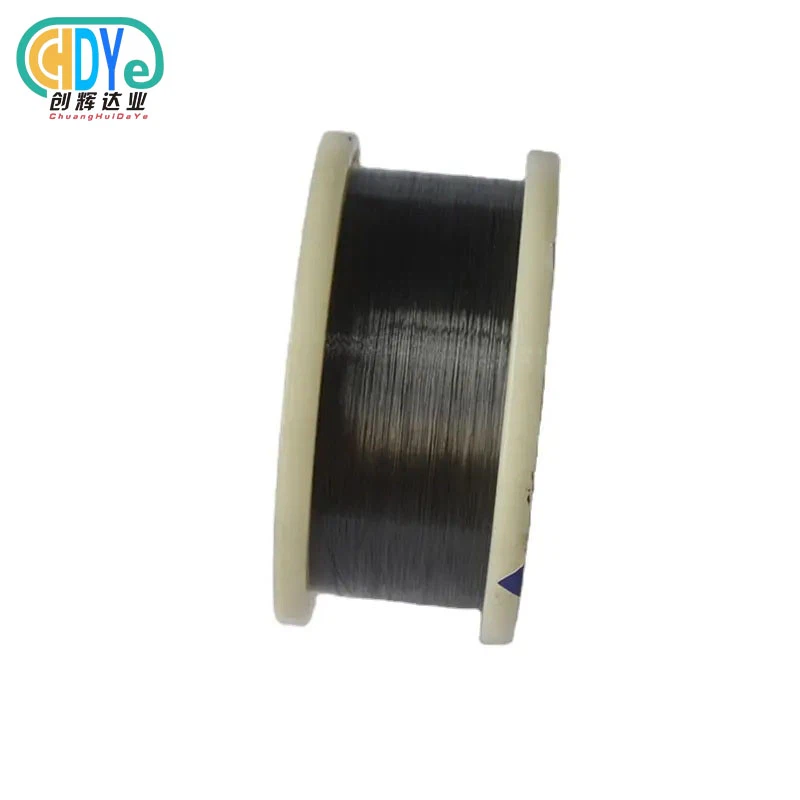

Type |

Straight,Coil, Spool |

| Certificate | ISO 9001:2015 |

|

Processing |

Bar billets-hot rolling-drawing-annealing-strength-pickling |

|

Standard |

ASTM B863, AWS A5.16, ASTM F67, ASTM F136 |

|

Features |

1. Super elasticity good plasticity, with memory function |

|

Packing term |

Foam plastic inside, wooden box outside |

|

Payment term |

30TT in advance, 70% balance payment before shipment |

Chemical composition

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Available Grades and Materials

We offer different titanium grades to suit your specific requirements. Grade 2 (commercially pure titanium) provides excellent corrosion resistance and formability. Grade 5 (Ti-6Al-4V) offers higher strength for demanding applications.

Each grade maintains consistent quality throughout the wire length. You can choose the grade that best matches your project requirements and budget considerations.

Manufacturing Process

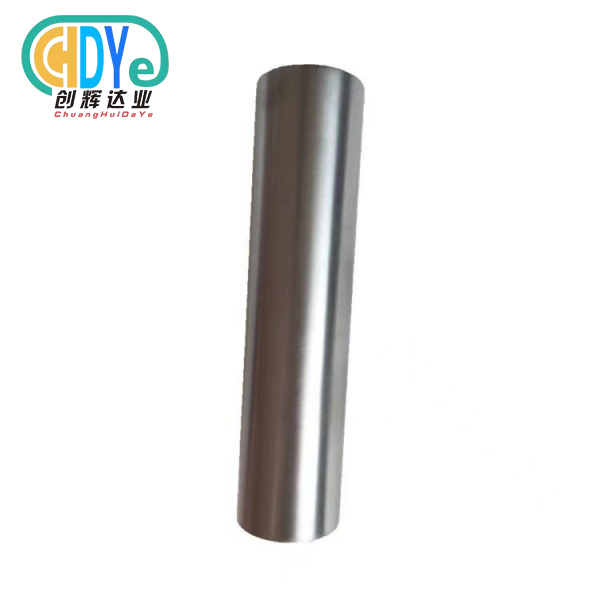

Our manufacturing process begins with high-quality titanium rods. We use precision wire drawing techniques to achieve the exact 0.81mm diameter. Multiple drawing passes ensure uniform diameter and smooth surface finish.

The annealing process optimizes the wire's mechanical properties. We carefully control temperature and time to achieve the desired strength and ductility balance. Quality checks occur at every manufacturing stage.

|

|

|

|

|

|

|

|

Applications and Industries

The versatility of our 20 gauge titanium wire makes it suitable for numerous applications. Welding applications benefit from its clean burning characteristics and strong joints. Jewelry makers appreciate its hypoallergenic properties and attractive appearance.

Industrial applications include chemical processing equipment, aerospace components, and marine hardware. Medical device manufacturers use it for implants and surgical instruments. The wire also works well

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Our standard diameter tolerance is ±0.02mm, ensuring consistent performance across your entire order. The wire comes in various lengths from 100mm to 6000mm, with custom lengths available upon request.

We maintain strict dimensional control throughout production. Each coil receives individual inspection to verify diameter consistency and surface quality.

Product Features in Detail

The exceptional corrosion resistance comes from titanium's natural oxide layer formation. This protective layer reforms automatically when damaged, providing long-lasting protection. You'll find this particularly valuable in marine and chemical environments.

The biocompatibility means the wire won't cause adverse reactions in biological applications. This makes it ideal for medical implants, dental work, and body jewelry. The non-magnetic properties add versatility for electronic applications.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including tensile strength, elongation, and dimensional verification. We maintain certificates of compliance with international standards. Our quality management system ensures consistent product quality.

Material traceability allows us to track each wire's production history. This documentation supports your quality requirements and regulatory compliance needs.

|

|

|

OEM & Customization Services

We understand that standard specifications don't always meet unique requirements. Our customization services include special lengths, packaging configurations, and surface treatments. We work closely with you to develop solutions for specific applications.

Our engineering team can recommend the best grade and specifications for your intended use. We also offer technical support throughout your project development process.

Packaging and Shipping

Standard packaging includes protective spools or coils to prevent damage during transport. We use moisture-resistant packaging to maintain wire quality. Special packaging options are available for sensitive applications.

Our global shipping network ensures timely delivery to over 50 countries. We work with reliable logistics partners to provide safe, efficient transportation of your 20 gauge titanium wire orders.

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, we understand your quality requirements. Our location in China's "Titanium Capital" provides access to premium raw materials and specialized manufacturing expertise.

We focus on customer satisfaction through competitive pricing, on-time delivery, and responsive service. Our commitment to continuous improvement ensures you receive the best products and service experience.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small and large orders. Contact us for specific quantity requirements.

Q: Can you provide material certificates?

A: Yes, we provide complete material certificates with every shipment.

Q: Is the wire suitable for welding applications?

A: Absolutely. Our 20 gauge titanium wire works excellently for various welding applications.or can make customized for your application. Just feel free to contact us.

Contact Us

Ready to experience the quality and reliability of our titanium wire? Contact our team today at info@chdymetal.com. We're here to help you find the perfect solution for your project needs and answer any questions you may have about our products and services.

Learn about our latest products and discounts through SMS or email