- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Grade 2 Titanium Wire

2.State:Annealing state (M) Hot working state (R) Cold working state (Y) (Annealing, ultrasonic testing)

3.Surface:Pickled surface and bright finishbr>

Product Overview

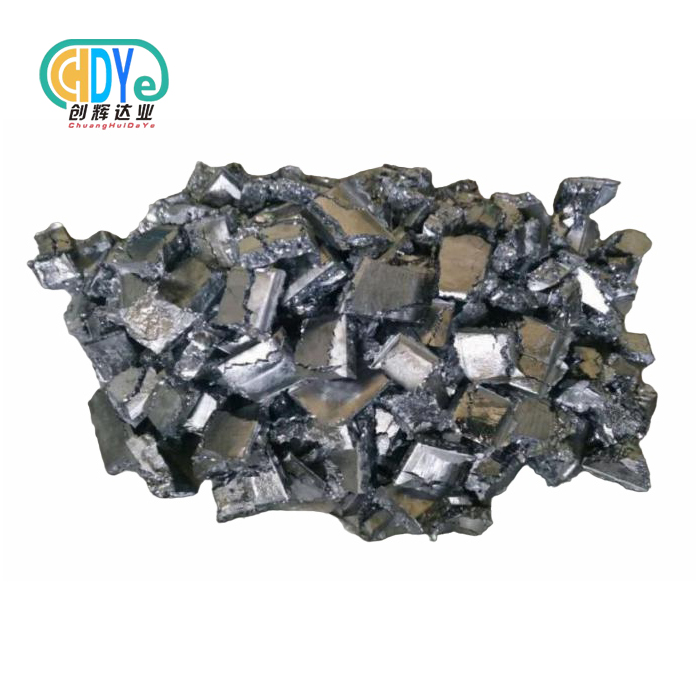

Grade 2 Titanium Wire is a commercially pure titanium product renowned for its excellent corrosion resistance, moderate strength, and superior formability. Produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd., our Grade 2 wire is manufactured under precise metallurgical control in Baoji—China’s world-famous “Titanium Capital.”

This material is particularly suitable for applications that demand lightweight, corrosion-resistant performance without sacrificing ductility or weldability. With over 30 years of titanium manufacturing experience, we guarantee consistent mechanical performance, surface finish, and dimensional precision for every spool or coil we supply.

Titanium wire is divided into: titanium wire, titanium alloy wire, pure titanium eyeglass wire, titanium straight wire, pure titanium wire, titanium welding wire, titanium hanger wire, titanium wire coil, titanium bright wire, medical titanium wire, and titanium nickel alloy wire.

Specification

A. Titanium wire specification: 0.8mm - 6.0mm

B. Specification of glasses titanium wire: 1.0mm - 6.0mm

C. Titanium wire specification: 0.2mm - 8.0mm

Main standards and Grade

AWS,ASTM,AMS,JIS

GR2 and other Grade GR1,GR3,GR5 Ti6AL4V ELI,Ti6AL7Nb,Ti13Nb13Zr,Ti1533 can be customized

The state of Titanium Wire

Annealing state (M)

Hot working state (R)

Cold working state (Y) (Annealing, ultrasonic testing)

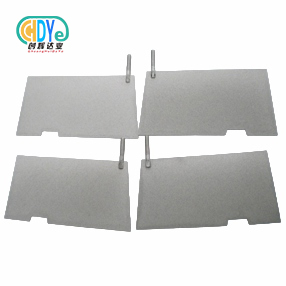

Surface Treatment

Pickled surface and bright finish

Application

Industries such as military, medical, sports goods, glasses, earrings, headwear, electroplating hangers, welding wires, etc.

Inventory List

Shaanxi Chuanghui Daye Metal Material Co.,Ltd have Grade 2 titanium wire in stocl all year round. Pls check the inverntory list below:

Customized services are also available.

|

|

|

|

|

|

1 |

Gr1 |

φ0.2 φ0.3 φ0.4 φ0.5 φ0.6 φ0.8 φ1.0 |

|

|

2 |

Gr2 |

||

|

3 |

Gr3 |

||

|

4 |

Gr4 |

||

|

5 |

Gr5 |

||

|

6 |

Gr7 |

||

|

7 |

GR12 |

||

|

8 |

ERTi-1 |

φ1.0 φ1.2 φ1.5 φ1.6 φ2.0 φ2.4 φ2.5 |

titanium welding wire |

|

9 |

ERTi-2 |

||

|

10 |

ERTi-3 |

||

|

11 |

ERTi-4 |

||

|

12 |

ERTi-5 |

||

|

13 |

ERTi-7 |

||

|

15 |

ERTi-9 |

||

|

16 |

ERTi-16 |

||

|

17 |

ERTi-17 |

MOQ: No MOQ we support samples order and your testing

Key Features & Advantages

-

Exceptional Corrosion Resistance

Excellent resistance to oxidizing and mildly reducing environments, ideal for seawater, chlorides, and acid conditions. -

Outstanding Weldability and Formability

Grade 2 titanium wire is easy to form, bend, and weld without cracking or degradation, suitable for precision fabrication and welding filler. -

Superior Biocompatibility

Non-toxic and non-reactive, making it perfect for surgical implants, medical devices, and dental frameworks. -

Lightweight with High Strength

Offers a unique balance between low density and adequate mechanical strength, supporting lightweight structural design. -

Thermal and Electrical Stability

Maintains consistent performance under high-temperature or electrically demanding environments. -

Reliable Process Control

Manufactured through multiple refining, annealing, and drawing steps, ensuring smooth surface and stable grain structure.

Manufacturing & Process Flow

The entire production process is managed in-house to maintain full traceability and quality reliability:

- Raw Material Selection – Only high-purity titanium sponge from certified sources.

- Vacuum Arc Melting (VAR) – Produces dense, homogeneous ingots with minimal impurities.

- Hot Forging & Rolling – Achieves refined grain structure for excellent ductility.

- Cold Drawing & Multi-Pass Reduction – Controls diameter precision and surface quality.

- Annealing Treatment – Restores flexibility and stress relief while maintaining strength.

- Straightening & Cutting – Available in coils, spools, or custom-cut straight wires.

- Final Cleaning & Inspection – Ultrasonic cleaning and 100% visual inspection before shipment.

|

|

|

|

|

|

|

|

Mechanical & Surface Performance

| Property | Unit | Grade 2 Typical Value |

|---|---|---|

| Tensile Strength | MPa | 345–485 |

| Yield Strength | MPa | 275–450 |

| Elongation | % | ≥20 |

| Hardness | HV | 160–200 |

| Density | g/cm³ | 4.51 |

| Surface Roughness (Ra) | μm | ≤0.8 |

| Conductivity | % IACS | 3–5 |

The wire exhibits a smooth, oxide-free surface with consistent grain orientation—ideal for welding and machining processes.

Quality Control & Inspection

Every step follows the ISO 9001:2015 quality management system, ensuring international compliance:

-

Chemical Composition Verification (ICP & Spectrometer)

-

Tensile & Elongation Testing

-

Surface and Diameter Inspection (Laser Measurement)

-

Eddy Current & Ultrasonic Defect Detection

-

Documentation Traceability – Each batch is accompanied by mill test certificates (MTC) and inspection reports.

We also welcome third-party inspection (SGS, BV, TUV) at the client’s request.

Application Advantages

Our Grade 2 Titanium Wire is trusted by industries worldwide due to its chemical stability and versatility:

- Medical Equipment: implant wire, surgical staples, orthodontic components

- Chemical Industry: anodes, cathodes, and fasteners for corrosive environments

- Aerospace Engineering: binding wire, structural reinforcement, and control systems

- Marine Construction: anti-corrosion fixtures and underwater cables

- Electronics & Energy: lead wires for electrolysis and battery connectors

- Automotive Components: lightweight exhaust and suspension systems

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Packaging & Global Logistics

Our packaging ensures total protection during international delivery:

- Inner Packaging: Vacuum or anti-rust film wrapping

- Outer Packaging: Reinforced wooden boxes or iron drums

- Identification: Each package labeled with grade, dimension, batch number, and net weight

- Logistics: Air freight, sea freight, or express courier service available

- Lead Time: 7–10 days for stock sizes; 15–20 days for custom specifications

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Services

We provide extensive customization to support OEM and project-based needs:

- Diameter and tolerance customization

- Bright, polished, or matte finishes

- Spool, coil, or straight form options

- Special-grade development (Gr1, Gr3, Gr5, etc.)

- Engineering consultation and rapid prototyping support

Our professional R&D team collaborates closely with clients to develop wire materials that meet specific environmental, electrical, or mechanical requirements.

Why Choose Us

-

Over 30 Years of Titanium Manufacturing Expertise

- Full-Process Quality Control from Melting to Machining

- Flexible Customization (Dimensions, Surface Finish, Coil Size)

- Fast Delivery and Competitive Pricing Direct from Factory

- Strong Technical and After-Sales Support

- Global Client Network Covering 50+ Countries

We don’t just supply materials—we deliver solutions tailored to your performance and budget goals.

|

|

|

|

|

|

FAQ

Q1: What makes Grade 2 titanium wire different from Grade 1?

A1: Grade 2 has slightly higher oxygen content, offering greater strength while maintaining excellent formability and corrosion resistance.

Q2: Can Grade 2 wire be used for TIG welding?

A2: Yes. It is commonly used as a filler wire for welding pure titanium components due to its stable arc and clean weld appearance.

Q3: Do you support small batch orders or prototype quantities?

A3: Absolutely. We welcome prototype, sample, and trial orders before mass production.

Q4: What quality certificates can you provide?

A4: ISO 9001:2015, mill test certificate (EN 10204 3.1), and customized third-party inspection reports.

Q5: How long does shipping take to Europe or North America?

A5: Typically 5–10 days by air or 20–30 days by sea, depending on order size and destination.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email