- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ru-ir Coated Titanium Anode

Ru-ir coated titanium anode is one of our main products, more details as below:

Product Introduction

Titanium anode is the anode in titanium-based metal oxide coating. It has oxygen evolution function and chlorine evolution function according to the different catalytic coatings on its surface. Generally, electrode materials should have good conductivity, small change in pole distance, strong corrosion resistance, good mechanical strength and processing performance, long life, low cost, and good electrocatalytic performance for electrode reaction. Titanium is the metal that best meets the above comprehensive requirements, and industrial pure titanium GR1 and Gr2 is generally used.

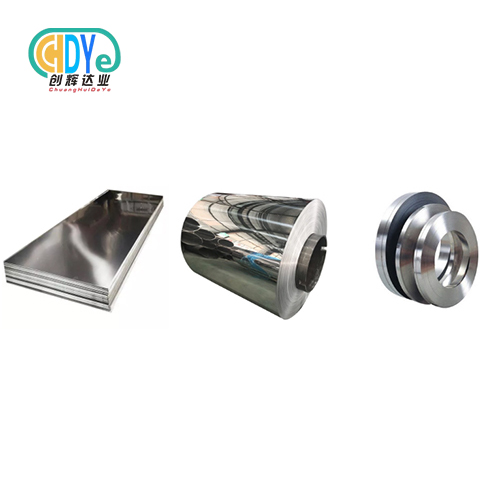

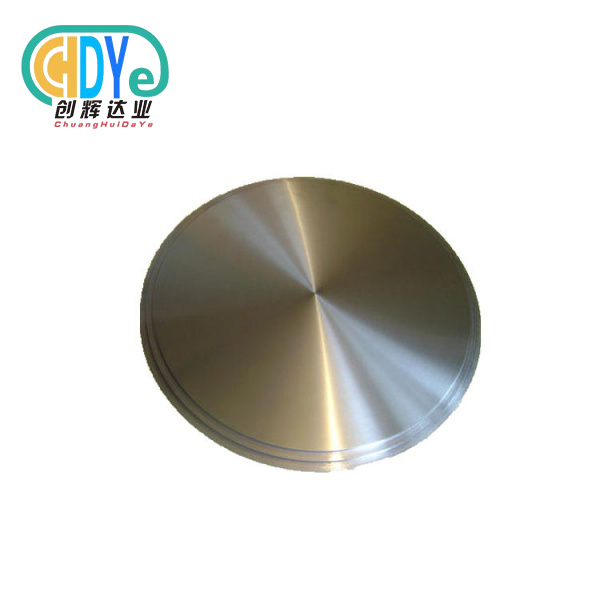

Chdymetal can provide various titanium anodes, customized is accepted. Ru-ir coated titanium anode is one of our main products, more details as below:

|

Substrate: pure titanium |

coating: RuO2+X |

|

Current density:≤1000 A/m² |

Coating content≥10g/ m² |

|

Coating thickness≥ 10μm |

Oxygen evolution potential1.13 v relative to calomel electrode |

Dimension and shape:

1. Plate/Tube/Rod/Mesh shape, different dimension is available

2. or according to client's drawing

3. MOQ: Flexible /Sample Order: Acceptable

Titanium anode various type

Application Advantages

Advantages:

1) Improving anode oxidizability by adding base metal Stannum

2) Low chlorine potential (≤1.13V), high sodium hypochloride efficiency

3) Stable chemical properties and high catalytic activity

Application:

Sodium hypochlorite generator

Cooling water system use anode

Seawater purification

Mariculture

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Each Ru-Ir Coated Titanium Anode is produced using advanced surface treatment and thermal coating technology to guarantee coating adhesion and uniformity.

Production Process:

Material Selection:

High-purity titanium plates (Grade 1 or Grade 2) are selected as substrates for their strength and corrosion resistance.

Surface Preparation:

The titanium surface is degreased, sandblasted, and acid-etched to enhance coating adhesion.

Available Coating Ratios:

Typical Ru:Ir ratios range from 70:30, 60:40, or customized based on electrochemical application requirements.

-

Coating Application:A Ru-Ir oxide precursor solution is evenly applied to the substrate by precision spraying or brushing.

-

Thermal Decomposition:Each layer undergoes heat treatment at controlled temperature ranges (450–550°C) to form a stable oxide crystalline structure.

-

Layer Repetition:Multiple coating and baking cycles are applied to achieve the desired coating thickness and catalytic activity.

-

Final Testing:Coating uniformity, adhesion, and electrochemical performance are verified before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is central to our operations.

We are ISO 9001:2015 certified and maintain a full traceability system for all titanium seamless tube production. Every step—from raw material inspection to final delivery—is carefully monitored to ensure product reliability and compliance.

Comprehensive testing methods include:

- Mechanical property tests (tensile, yield, elongation)

- Non-destructive testing (ultrasonic and eddy current)

- Dimensional and visual inspections

- Corrosion resistance and metallographic analysis

Only after passing all evaluations are products released for shipment.

R&D and Customization

- Customized mechanical strength and elongation through controlled annealing

- Tailored coil or straight length for automated production lines

- Surface finish customization: pickled, mirror-polished, or bright annealed

- OEM packaging, logo, and labeling for international distributors

- Prototype development for advanced alloys and new applications

Our R&D team continuously works with aerospace, chemical, and medical sectors to optimize titanium wire performance and cost-efficiency.

Packaging & Global Logistics

Each Ru-Ir Coated Titanium Anode is carefully packaged and shipped according to international export standards to ensure it arrives safely and ready for installation.

Packaging Method:

- Inner: Anti-rust film and vacuum sealing

- Intermediate: Foam and bubble wrap for mechanical protection

- Outer: Export-standard wooden cases with waterproof treatment

- Labeling: Product name, size, coating type, batch number, and inspection certificate

Logistics Options:

- Air Freight: Fast shipping for urgent deliveries (3–7 days)

- Sea Freight: Economical and secure transport for bulk orders

- Land Delivery: Reliable domestic or regional logistics for short-distance orders

We maintain partnerships with international logistics companies to ensure safe, timely, and traceable delivery to over 50+ export markets worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

As a professional manufacturer, Shaanxi Chuanghui Daye offers full OEM and ODM services for global customers seeking tailored Ru-Ir coated titanium anodes.

OEM/ODM Capabilities Include:

- Coating customization based on electrolyte type and current density

- Custom sizes, designs, and terminal configurations

- Private branding and labeling services

- Small-batch sample production and mass manufacturing

- Technical consultation for process optimization and performance evaluation

Our engineering team collaborates directly with customers to ensure every anode meets precise industrial specifications and application goals.

Inspection Process

Each anode undergoes a comprehensive inspection process before delivery to ensure consistent quality and long service performance.

Inspection Steps:

- Raw material validation and titanium certificate check

- Surface pretreatment verification (roughness, cleanliness)

- Coating application and thermal treatment control

- Coating adhesion and thickness testing

- Electrochemical performance simulation test

- Dimensional and surface flatness measurement

- Visual inspection for coating defects

- Packaging verification and labeling approval

Inspection records are fully traceable, ensuring accountability and repeatable production quality.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is recognized as a leading manufacturer of titanium-based and rare metal-coated anodes in China’s “Titanium Capital”—Baoji City.

Our Strengths:

- Over 30 years of expertise in rare metal and coating technologies

- ISO 9001:2015 certified quality system

- Advanced coating furnaces, machining, and inspection equipment

- Strong R&D and OEM customization capability

- Fast delivery within 7–10 days for standard orders

- Global export experience in 50+ countries

- Dedicated customer service and full technical support

We strive to deliver cost-effective, durable, and high-performance Ru-Ir titanium anodes to partners worldwide.

|

|

|

|

|

|

FAQs

Q1: What is the function of Ru-Ir coated titanium anodes?

A1: They are used as dimensionally stable anodes in electrochemical processes such as electrochlorination, metal electrowinning, and water treatment.

Q2: What’s the typical Ru:Ir ratio in the coating?

A2: Common ratios are 70:30 or 60:40, but we can adjust the composition according to your process requirements.

Q3: How long is the service life of a Ru-Ir coated titanium anode?

A3: Typically between 3 to 8 years depending on current density, electrolyte type, and coating thickness.

Q4: Can you produce customized shapes and sizes?

A4: Yes, we support customization for plate, mesh, or tubular anodes based on customer drawings.

Q5: Do you provide coating performance test reports?

A5: Yes, all products are delivered with inspection certificates, coating composition analysis, and performance test data.

Q6: What are the typical applications of this anode?

A6: Electrochlorination systems, seawater disinfection, electroplating, metal recovery, and cathodic protection systems.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1760924769851.jpg)