- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

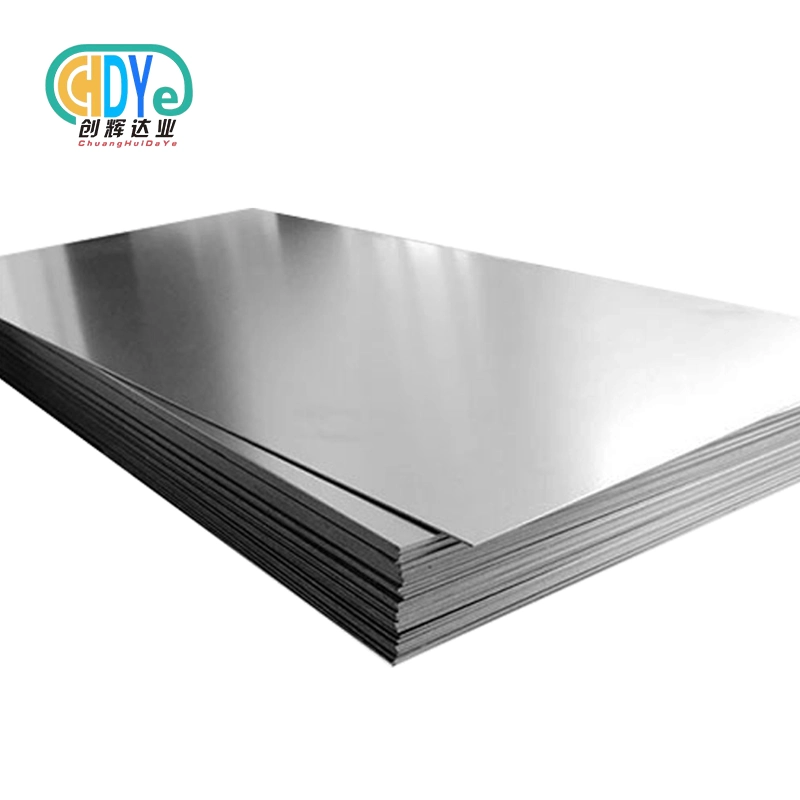

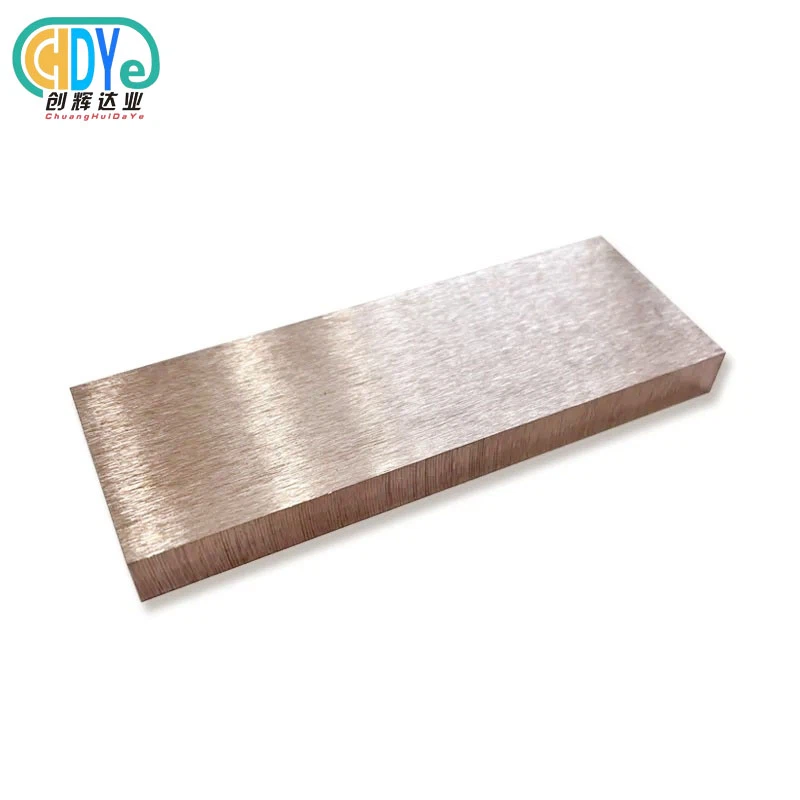

titanium alloy plates

2. Thickness 0.5-50mm

3. Width up to 2000mm

4. Length 1000-6000mm

5. Lightweight and durable

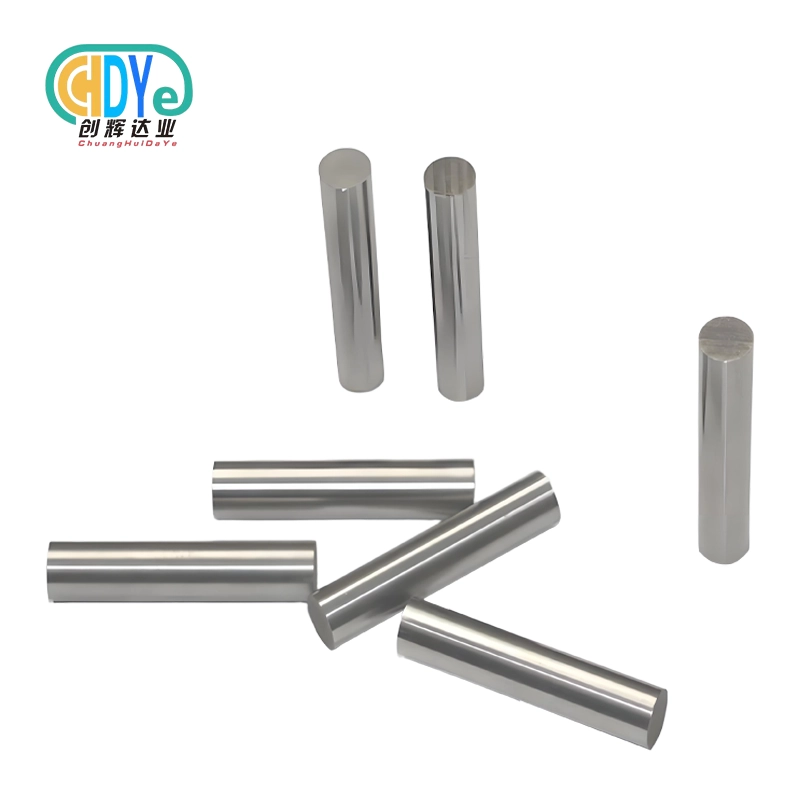

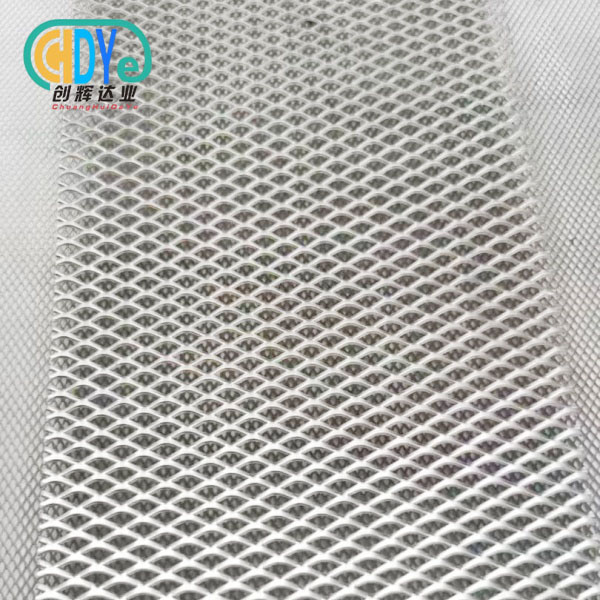

6.Type: plate, sheet, strip and foil are all available

6. Corrosion resistant

Production introduction

Looking for high-performance titanium alloy plates that deliver exceptional strength and corrosion resistance? You've come to the right place. Our titanium alloy plates combine lightweight properties with superior durability, making them perfect for demanding industrial applications. Whether you need plates for aerospace, marine, or chemical processing, we offer multiple grades and custom dimensions to meet your specific requirements. With over 30 years of experience in rare metal manufacturing, we ensure every plate meets the highest quality standards.

Key Features and Benefits

Our titanium plates offer remarkable advantages that set them apart from conventional materials. You'll benefit from their exceptional strength-to-weight ratio, which reduces overall project weight without compromising performance. The natural corrosion resistance means longer service life in harsh environments, reducing replacement costs and maintenance downtime.

These plates maintain their properties across wide temperature ranges, from cryogenic conditions to elevated temperatures. Their biocompatibility makes them ideal for medical applications, while their excellent formability allows for complex fabrication processes. You can expect consistent quality and reliable performance in every plate we deliver.

Technical Specifications

Our plates feature impressive mechanical properties with tensile strengths ranging from 30,000 to 200,000 psi (210-1380 MPa). The density typically ranges from 4.43 to 4.62 g/cm³, depending on the specific grade. Young's modulus stands at approximately 114 GPa, providing excellent stiffness characteristics.

Temperature resistance extends from -269°C to 600°C for most grades. The coefficient of thermal expansion remains low at 8.6 × 10⁻⁶/°C, ensuring dimensional stability. Electrical resistivity varies by grade but typically ranges from 170 to 1700 nΩ·m.

Available Grades and Materials

We supply various titanium grades to match your application needs:

- Grade 1 (CP-1): Maximum corrosion resistance, excellent for chemical processing

- Grade 2 (CP-2): Most commonly used, good balance of properties

- Grade 5 (Ti-6Al-4V): Highest strength, aerospace and medical applications

- Grade 7: Enhanced corrosion resistance with palladium addition

- Grade 12: Superior strength and corrosion resistance

Each grade offers unique characteristics tailored for specific environments and performance requirements.

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Manufacturing Process

Our manufacturing process begins with premium raw materials sourced from certified suppliers. We use advanced vacuum arc remelting (VAR) technology to ensure homogeneous composition and eliminate impurities. The ingots undergo controlled hot rolling at precise temperatures to achieve optimal grain structure.

Heat treatment processes including annealing, solution treatment, and aging are carefully controlled to achieve desired mechanical properties. Surface finishing options include pickled, polished, or as-rolled conditions. Every step follows strict quality protocols to ensure consistent results.

|

|

|

|

|

|

|

|

Applications and Industries

Titanium alloy plates serve critical roles across numerous industries. In aerospace, they're essential for aircraft structures, engine components, and landing gear systems. The chemical processing industry relies on them for reactor vessels, heat exchangers, and pipeline systems where corrosion resistance is paramount.

Medical applications include surgical implants, prosthetics, and medical device components due to their biocompatibility. Marine environments benefit from their seawater corrosion resistance in offshore platforms, ship components, and desalination equipment. Power generation facilities use them in turbine blades, condenser tubes, and steam generator components.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We offer flexible sizing options to meet your project requirements:

- Thickness: 0.5mm to 50mm

- Width: Up to 2000mm

- Length: 1000mm to 6000mm

- Thickness tolerance: ±0.05mm to ±0.5mm depending on thickness

- Width tolerance: ±2.0mm

- Length tolerance: ±5.0mm

Custom dimensions are available upon request with competitive lead times.

Quality Assurance and Testing

Every plate undergoes comprehensive testing including chemical composition analysis, mechanical property verification, and non-destructive testing. We perform ultrasonic testing to detect internal defects and conduct surface inspection for finish quality.

Tensile testing, hardness measurements, and grain size analysis ensure mechanical properties meet specifications. Chemical analysis verifies composition accuracy within tight tolerances. All testing follows international standards including ASTM and GB specifications.

|

|

|

OEM & Customization Services

We specialize in custom solutions tailored to your specific needs. Our engineering team works closely with you to determine optimal grade selection, dimensions, and surface treatments. We can provide custom packaging, labeling, and delivery schedules to support your production requirements.

Value-added services include precision cutting, surface treatments, and quality documentation packages. Our flexibility allows us to accommodate both prototype quantities and large production runs.

Packaging and Shipping

We ensure safe delivery through professional packaging methods. Plates are protected with plastic film, separated by foam padding, and secured in wooden crates for international shipping. Each package includes detailed labeling with grade, dimensions, and heat lot numbers.

Our logistics team coordinates with reliable carriers to ensure timely delivery worldwide. We provide tracking information and work with your schedule to minimize project delays.

Why Choose Us

Located in Baoji, China's "Titanium Capital," we leverage three decades of industry expertise to deliver superior products. Our founder's extensive experience in rare metals ensures deep understanding of customer needs and technical requirements.

We maintain competitive pricing through efficient operations while never compromising quality. Our global reach spans over 50 countries, demonstrating proven reliability in international markets. Customer-focused service, on-time delivery, and continuous improvement define our commitment to your success.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from small prototype quantities to large production runs based on your needs.

Q: How long is the typical lead time?

A: Standard grades typically ship within 1-2 weeks, while custom specifications may require 2-3 weeks.

Q: Do you provide material certificates?

A: Yes, we provide complete mill test certificates with chemical composition and mechanical properties for every shipment.

Contact Us

Ready to discuss your titanium alloy plate requirements? Our technical team is here to help you select the right grade and specifications for your application. Contact us today at info@chdymetal.com for quotes, technical support, or to learn more about our comprehensive titanium solutions. We look forward to partnering with you on your next project.

Learn about our latest products and discounts through SMS or email