- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

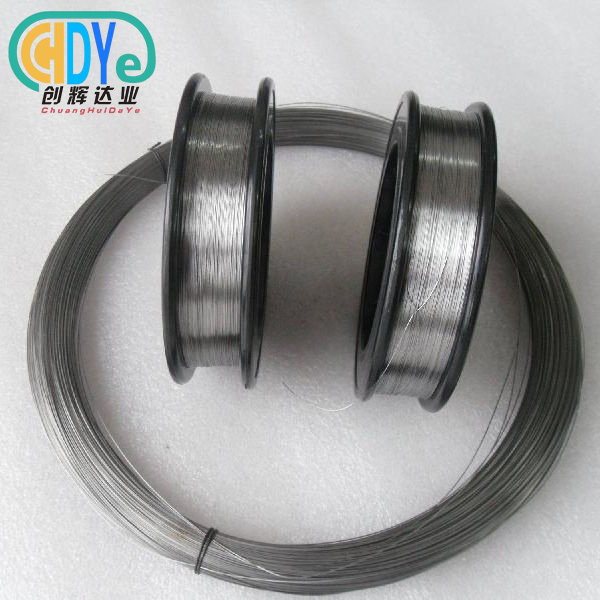

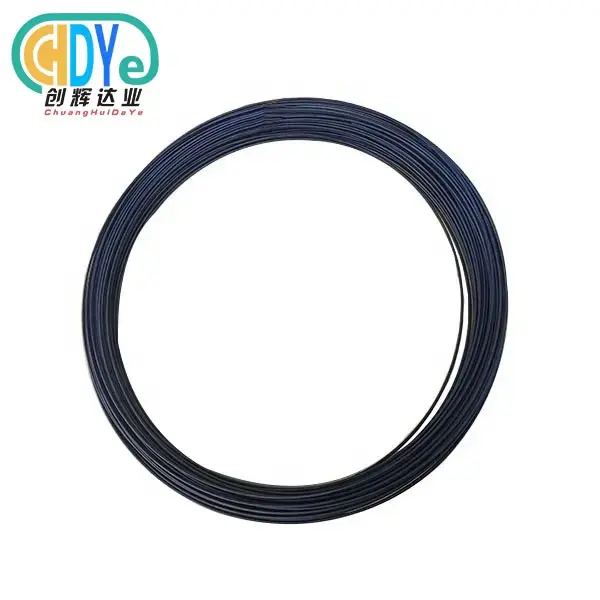

Titanium Anode Wire For Cathode Protection

2.Current density 50-100 A/m2

3.Design life: 30 years

Product Introduction

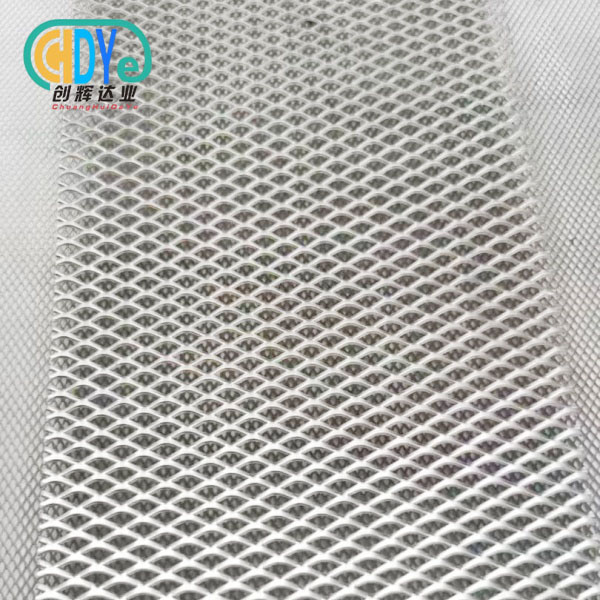

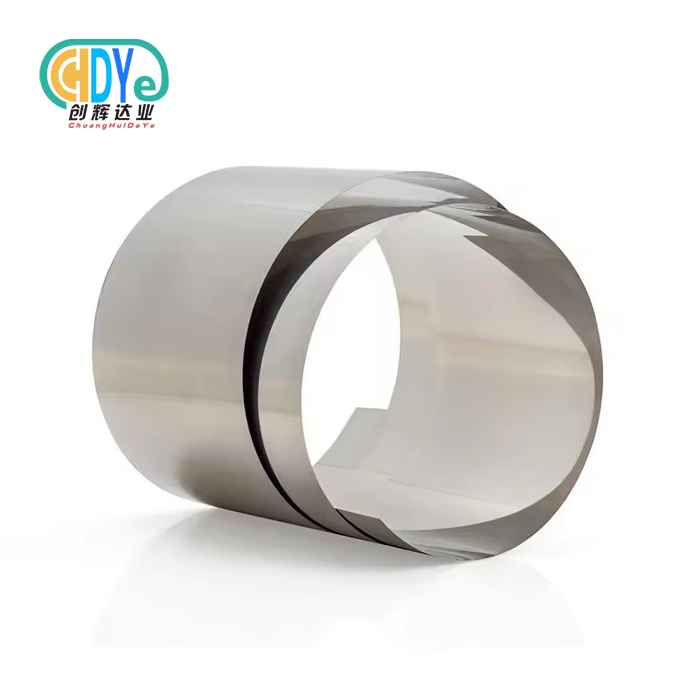

Titanium Anode Wire for Cathode Protection is manufactured by coating high-purity titanium wire with a durable Iridium–Tantalum Mixed Metal Oxide (MMO) coating. This advanced coating provides excellent corrosion resistance and electrical conductivity, making the product ideal for various environments such as soil, carbonaceous backfill, fresh water, brackish water, and seawater. It ensures reliable performance and extended service life in cathodic protection systems.

|

Titanium conductive sheet |

|||||||

|

base material |

titanium |

nitrogen (N) |

carbon |

hydrogen (H) |

iron |

oxygen |

Total impurity |

|

ASTM B 265 Gr 1/2 |

balance |

<0.03% |

<0.08% |

<0.015% |

<0.30% |

<0.25% |

<0.40% |

Features of Titanium Anode Wire for Cathode Protection

- Lightweight and easy to handle, simplifying field installation.

- No on-site spot welding required, ensuring faster setup.

- Cost-effective solution with lower cost per ampere-year.

- High stability and reliable long-term performance.

Advantages of Titanium Anode Wire for Cathode Protection

- Extended Service Life: The durable mixed metal oxide coating significantly increases anode lifespan.

- Simple Installation: Designed for quick and convenient operation without complex procedures.

- Excellent Current Distribution: Adjustable wire length allows for optimized and uniform current flow.

- Corrosion Resistance: Performs reliably in harsh environments including seawater and soil.

This Titanium Anode Wire for Cathode Protection provides an economical, stable, and maintenance-free solution for long-term corrosion prevention across multiple industries.

Application Advantages

Water Storage Tanks

Tank Bottom Anodes

Linear / flexible Anodes

Reinforced concrete structures.

Working Environment: including soil, carbonaceous backfill, fresh water, brackish water, and seawater.

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

Our Titanium Anode Wire for Cathodic Protection is produced through advanced coating and precision processing technologies to guarantee stability and uniform performance in all operational conditions.

Production Workflow:

- Titanium Material Selection: High-purity Grade 1 or Grade 2 titanium wire is used as the substrate.

- Surface Pretreatment: Cleaning, acid etching, and activation to enhance coating adhesion.

- Coating Application: Deposition of Ru-Ir, Ir-Ta, or mixed metal oxide (MMO) coatings through thermal decomposition or brush techniques.

- Heat Treatment: Controlled temperature treatment ensures strong coating bonding and electrochemical stability.

- Testing & Quality Control: Conductivity, coating adhesion, and electrochemical tests are performed.

- Packaging: Finished anode wires are wound, sealed, and packed for international shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye upholds strict ISO 9001:2015 quality control protocols to ensure each anode meets international cathodic protection standards.

Inspection Process Includes:

- Raw Material Verification: Confirm titanium grade and purity.

- Surface Quality Inspection: Check for defects, uniformity, and coating continuity.

- Coating Thickness & Adhesion Testing: Ensure consistent coating integrity.

- Electrochemical Testing: Measure potential stability and current output.

- Dimensional & Mechanical Testing: Verify diameter, flexibility, and tensile strength.

- Final Visual Inspection: Guarantee perfect surface finish before packaging.

All data and test reports accompany each batch, ensuring full traceability and reliability.

R&D and Customization

Our dedicated R&D team continuously enhances product performance through material innovation and advanced coating technology development.

R&D Focus Areas:

- Research on high-efficiency MMO coatings for extended lifespan.

- Optimization of current distribution and coating uniformity for varied soil and marine conditions.

- Design of custom wire configurations for linear or distributed anode systems.

- Development of hybrid titanium anodes combining MMO and noble metal coatings.

Customization Options:

- Wire diameter: 0.5 mm – 5 mm (customizable)

- Coating type: Ru-Ir, Ir-Ta, IrO₂, or mixed metal oxide systems

- Coating thickness: Tailored according to current density and design life

- Spool length: Up to several hundred meters per roll

- Titanium grade: Gr1 or Gr2 as standard

Packaging & Global Logistics

To ensure safety and product integrity during transportation, each Titanium Anode Wire is packaged according to international export standards.

Standard Packaging:

- Anti-rust film or vacuum-sealed wrapping

- Spools placed in foam-lined cartons or wooden crates

- Clear labeling with batch number and product specification

Logistics Options:

- Global delivery by air, sea, or land

- Express dispatch within 7 working days for standard products

- Complete shipping documentation and tracking service

All packaging materials are compliant with export and environmental regulations.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides complete OEM and ODM services for cathodic protection system manufacturers, project contractors, and engineering firms.

Our Service Includes:

- Customized wire length, diameter, and coating type

- Private label and logo engraving

- Engineering assistance for anode system design

- Prototype production and batch testing support

- After-sales technical consultation and troubleshooting

With professional manufacturing capacity and engineering expertise, we deliver efficient, durable, and cost-effective solutions for corrosion prevention worldwide.

Inspection Process

Each Titanium Anode Wire for Cathodic Protection is thoroughly inspected before delivery to ensure consistent quality and optimal performance.

- Material Certification Check – Confirm titanium grade (Gr1/Gr2) and compliance with ASTM/GB standards.

- Coating Uniformity Test – Examine surface uniformity under magnification.

- Adhesion Test – Evaluate bond strength between coating and substrate.

- Electrical Resistance Measurement – Verify stable current distribution and conductivity.

- Electrochemical Test – Simulate cathodic protection operation for performance validation.

- Final Packaging Inspection – Ensure protective wrapping and labeling accuracy.

Why Choose Us

- Over 30 Years of Experience: Established by an expert with deep knowledge in titanium and rare metal processing.

- Advanced Production Equipment: Equipped with electron beam furnaces, rolling machines, and precision coating systems.

- Certified Quality Management: ISO 9001:2015-certified system ensures complete process control.

- Global Market Coverage: Exported to more than 50 countries, including the USA, Germany, and South Korea.

- R&D Strength: Continuous improvement in MMO coating technology for high-efficiency cathodic protection.

- Flexible OEM Service: Tailor-made solutions to meet project-specific requirements.

- Fast Delivery: 7-day shipping for standard specifications.

- Responsive Support: Quick technical response and global customer assistance.

|

|

|

|

|

|

FAQs

Q1: What coating types are available for Titanium Anode Wire?

A1: We provide Ru-Ir, Ir-Ta, IrO₂, and mixed metal oxide (MMO) coatings, depending on the environment and design life.

Q2: Can the wire be supplied in custom lengths or spools?

A2: Yes. We offer custom spool sizes, wire lengths, and packaging according to project specifications.

Q3: What is the typical service life of your Titanium Anode Wire?

A3: Service life ranges from 20 to 50 years, depending on coating type, current density, and environment.

Q4: How do you ensure coating quality and uniformity?

A4: We use precision surface treatment and multiple quality tests, including coating adhesion and thickness inspection, before shipment.

Q5: Do you offer technical support for cathodic protection system design?

A5: Absolutely. Our technical team can provide material selection guidance, design optimization, and installation advice.

Q6: What is your lead time for bulk orders?

A6: Standard sizes can be shipped within 7–10 working days, while custom orders may take longer based on complexity.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email