- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

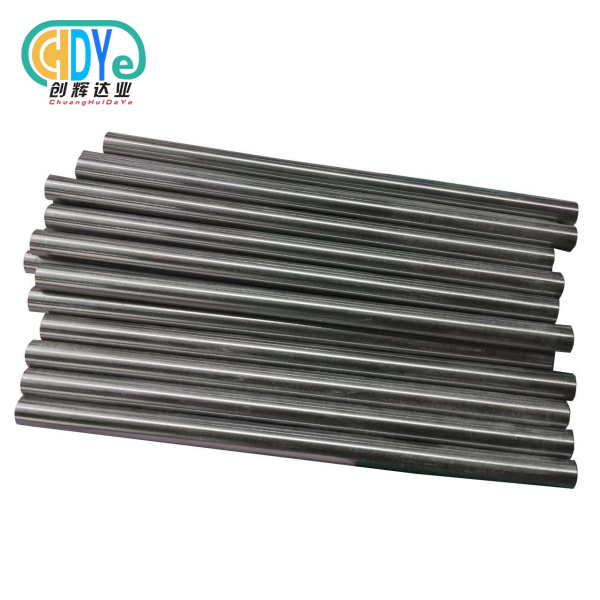

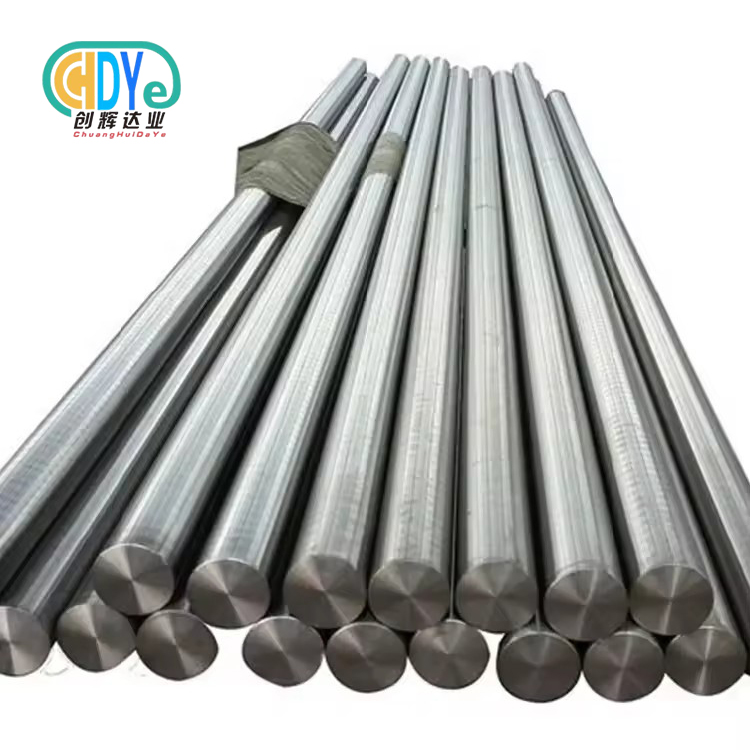

6al 4v titanium round bar

Looking for high-performance titanium solutions? Our 6al 4v titanium round bar delivers exceptional strength-to-weight ratio combined with outstanding corrosion resistance. This versatile Grade 5 titanium alloy contains 90% titanium, 6% aluminum, and 4% vanadium, making it the most widely used titanium grade worldwide. Whether you're in aerospace, medical, or industrial applications, our titanium round bars provide the reliability and performance your projects demand.

Key Features and Benefits

Superior Strength & Lightweight Design

Our Grade 5 titanium round bars offer remarkable strength while maintaining 40% less weight compared to steel. This unique combination makes them perfect for weight-critical applications.

Exceptional Corrosion Resistance

These bars resist corrosion in harsh environments including seawater, marine atmospheres, wet chlorine, and chlorine dioxide. Your components will maintain integrity even in challenging conditions.

Excellent Weldability

Using inert gas shielding, our titanium bars weld easily. Spot, seam, flash, and pressure welding techniques work well depending on your specific application needs.

Heat Treatment Capability

Strength properties can be enhanced through solution treatment and aging (STA), allowing you to customize performance characteristics for your specific requirements.

Technical Specifications

Chemical Composition:

- Titanium: 90%

- Aluminum: 6%

- Vanadium: 4%

Mechanical Properties:

- Yield Strength: 120 Ksi minimum (annealed condition)

- Excellent elevated temperature strength

- Superior low temperature impact strength

- Good creep resistance

|

Grade |

Mechanical properties at room temperature, not less than |

|||

|

tensile strength |

Yield Strength |

Elongation |

percentage reduction of area |

|

|

GR1 |

240 MPa |

170MPa |

25% |

30% |

|

GR2 |

345MPa |

275MPa |

20% |

30% |

|

GR5 |

895MPa |

825 MPa |

10% |

20% |

Standards Compliance:

- ASTM B348 / ASME SB348

- AMS 4928, AMS 4965, AMS 4967

Available Grades and Materials

We specialize in Grade 5 (Ti-6Al-4V) titanium, also known by these common trade names:

- Grade 5 Titanium

- Ti-6al-4v

- 6Al-4V Titanium

- UNS R56400

This alpha-beta type titanium alloy represents the workhorse of titanium materials, accounting for the majority of titanium applications worldwide.

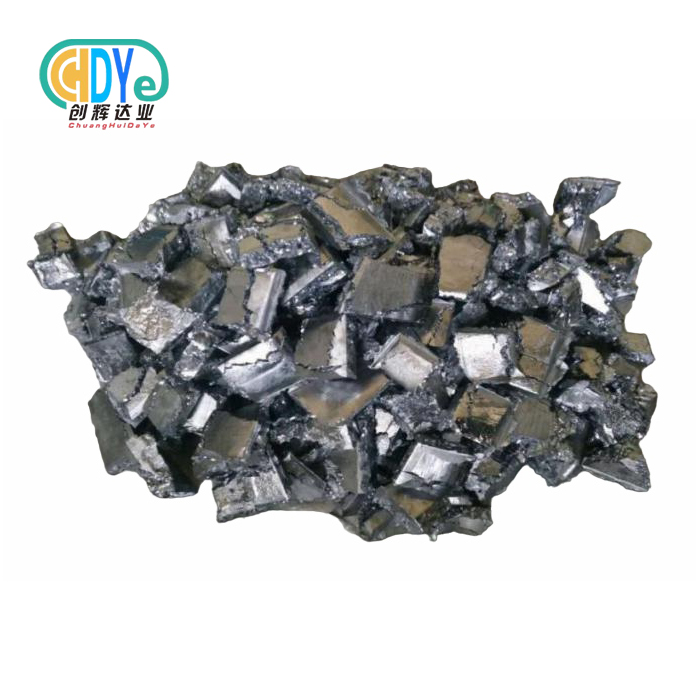

Manufacturing Process

Our 6al 4v titanium round bar production follows strict quality protocols:

Primary Melting: Starting with vacuum arc remelt (VAR), electron beam (EB), or plasma arc hearth melt (PAM)

Remelting Process: One or two-step remelting in VAR furnaces ensures material purity and consistency

Quality Control: Each batch undergoes rigorous testing to meet international standards

Final Processing: Precision machining and finishing to your exact specifications

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace Industry

Aircraft components, engine parts, and structural elements benefit from the lightweight yet strong properties.

Medical Sector

Biomedical implants and surgical instruments utilize the biocompatible and corrosion-resistant characteristics.

Marine Applications

Offshore equipment and marine hardware resist corrosion in saltwater environments.

Industrial Manufacturing

Chemical processing equipment, automotive components, and high-performance machinery parts.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Round Bar Specifications:

- Diameter Range: 6.0 – 350mm

- Standard Length: Up to 6000mm

- Cut-to-Size Tolerance: ± 1.0 mm (0.040 in)

Rod Specifications:

- Diameter Range: 3 – 70mm

- Maximum Length: 6000mm

We stock both metric and imperial sizes, with many non-standard dimensions available upon request.

Quality Assurance and Testing

Every 6al 4v titanium round bar undergoes comprehensive testing:

- Chemical composition analysis

- Mechanical property verification

- Dimensional inspection

- Surface quality assessment

- Traceability documentation

Our quality management system ensures consistent performance across all products.

OEM & Customization Services

We understand that every project has unique requirements. Our experienced team provides:

- Custom diameter and length specifications

- Special tolerance requirements

- Heat treatment services

- Machining and finishing operations

- Technical consultation and support

Packaging and Shipping

Your titanium round bars receive careful packaging to prevent damage during transit. We coordinate worldwide shipping to over 50 countries and regions, ensuring your materials arrive safely and on schedule.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metal industries, Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings unmatched expertise to every project. Located in China's "Titanium Capital," we combine local advantages with global reach.

Our Commitment:

- Competitive pricing

- On-time delivery

- Customer-focused service

- Reliability and honesty

- Continuous improvement

|

ISO9001:2015 |

ISO9001:2015 |

Feedback from customers

|

|

|

FAQs

Q: What makes Grade 5 titanium different from other grades?

A: Grade 5 offers the best balance of strength, formability, and corrosion resistance among titanium alloys.

Q: Can you provide custom lengths?

A: Yes, we cut all bars to your specified lengths with precise tolerances.

Q: What industries commonly use this material?

A: Aerospace, medical, marine, automotive, and chemical processing industries rely heavily on this versatile alloy.

Q: Do you provide material certificates?

A: Yes, complete traceability documentation accompanies every shipment.

Contact Us

Ready to discuss your 6al 4v titanium round bar requirements? Our technical team stands ready to help you select the perfect solution for your application.

Email: info@chdymetal.com

Contact us today for competitive pricing, technical specifications, and delivery information. Let us be your trusted partner for high-quality titanium solutions.

Learn about our latest products and discounts through SMS or email

_1760924447399.jpg)