- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Product Introduction

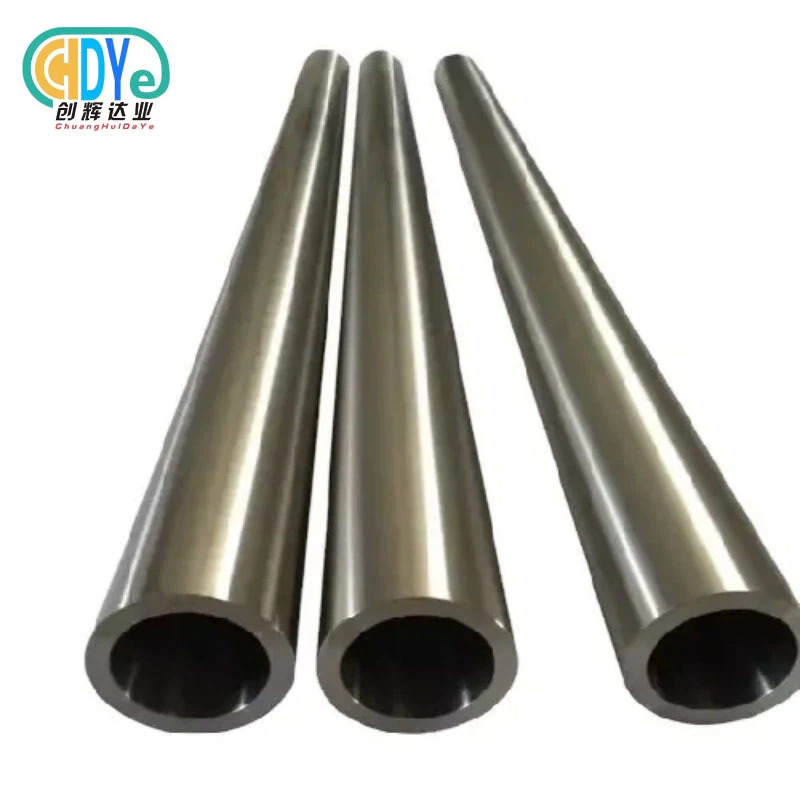

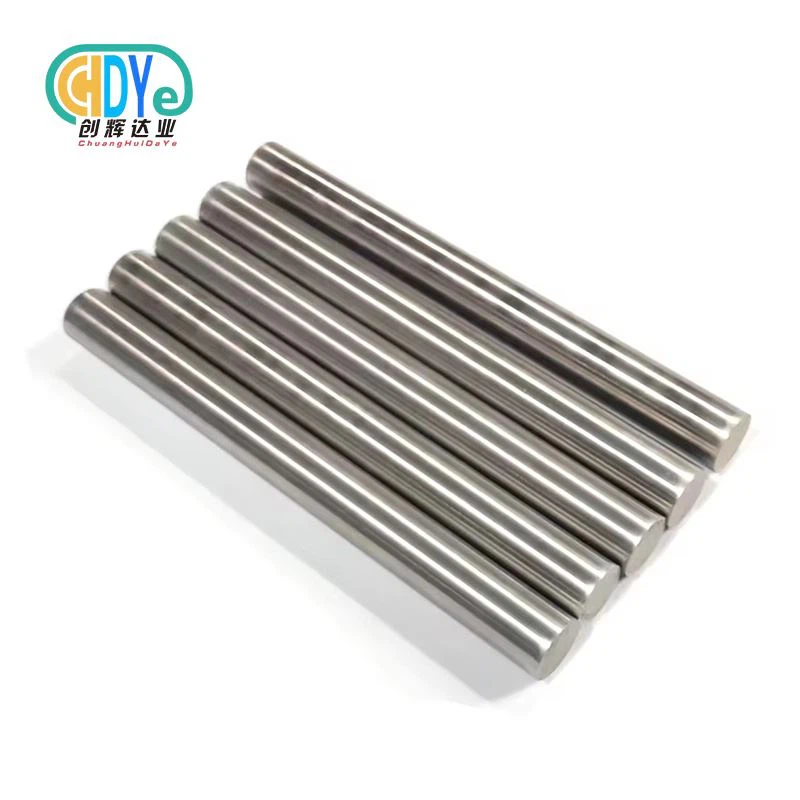

Looking for a reliable gr2 titanium square rod for your industrial applications? You've come to the right place. Our Grade 2 titanium square rod combine exceptional strength with outstanding corrosion resistance. These bars feature a unique six-sided profile that offers superior gripping properties and enhanced structural integrity. Made from commercially pure titanium with 99.2% titanium content, our square rod deliver the perfect balance of formability and durability. Each gr2 titanium square rodmeets strict ASTM B348 standards, ensuring consistent quality for your critical applications.

Key Features and Benefits

Our titanium square rod offer numerous advantages over traditional materials:

Lightweight Design: With a density of only 4.51 g/cm³, these bars are 60% lighter than steel while maintaining superior strength.

Excellent Corrosion Resistance: Your investment stays protected even in harsh chemical environments and marine applications.

Biocompatible Properties: Safe for medical and food-grade applications without compromising performance.

Easy Machining: The square shape provides excellent grip for machining operations and reduces slippage during processing.

Temperature Stability: Performs reliably from cryogenic temperatures up to 300°C in continuous service.

Technical Specifications

| Grade | Gr1 Gr2,Gr5,Gr7,Gr5 Ell,Gr9, Gr12 |

| Standard | ASTMB348,ASTMF67,ASTMF136 |

| Size | customized |

| Type | Round, Square, Hexagon |

| Processing method: | Forged and Rolled |

| Package Terms: | Moisture-proof cloth, foam cotton inside, wooden case outside. |

| Shipping Terms: | Express,Air,Shipping or as your choice. |

| Payment terms | 30% TT in advance, 70% balance before shipment |

Chemical Composition:

|

N |

C |

H |

Fe |

O |

Al |

V |

Pd |

Mo |

Ni |

|

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

|

Gr 11 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

0.12-0.25 |

/ |

/ |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Gr 16 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.04-0.08 |

/ |

/ |

|

Gr 17 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

0.04-0.08 |

/ |

/ |

Mechanical Properties:

- Tensile Strength: 344 MPa (49,900 psi)

- Yield Strength: 275 MPa (39,900 psi)

- Elongation: 20% minimum

- Modulus of Elasticity: 105 GPa

Physical Properties:

- Density: 4.51 g/cm³

- Melting Point: 1,665°C (3,030°F)

- Thermal Conductivity: 16.4 W/m-K

Available Grades and Materials

We specialize in Grade 2 titanium, also known as commercially pure titanium (CP-Ti). This grade offers the best combination of strength, ductility, and corrosion resistance for most applications. Our bars comply with:

- ASTM B348 Standard

- UNS R50400 Designation

- DIN 3.7035 Specification

- ASME SB-348 Requirements

Manufacturing Process

Our gr2 titanium square rod production follows strict quality protocols:

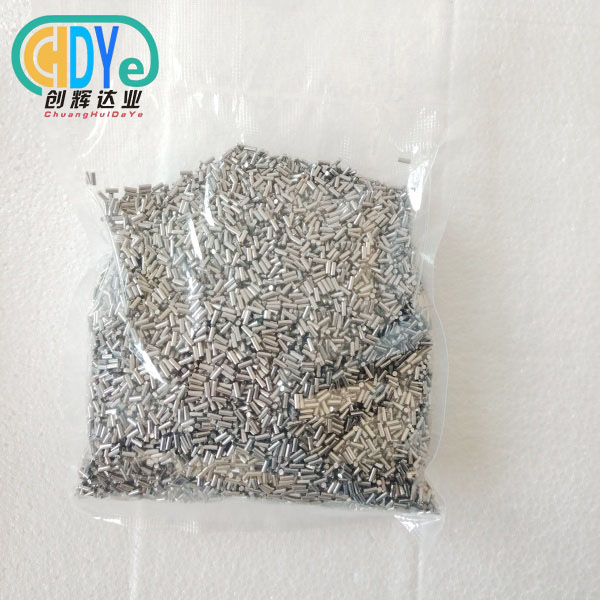

Raw Material Selection: We source premium titanium sponge from certified suppliers.

Melting Process: Vacuum arc remelting ensures chemical homogeneity and removes impurities.

Hot Working: Controlled forging and rolling create the desired square profile.

Heat Treatment: Stress relief annealing optimizes mechanical properties.

Precision Machining: Final sizing ensures dimensional accuracy and surface finish.

Quality Inspection: Each batch undergoes comprehensive testing before shipment.

|

|

|

|

|

|

|

|

Applications and Industries

Our titanium square bars serve diverse industries:

Aerospace: Aircraft fasteners, structural components, and engine parts requiring lightweight strength.

Medical Devices: Surgical instruments, implants, and prosthetics benefiting from biocompatibility.

Chemical Processing: Equipment components exposed to corrosive chemicals and high temperatures.

Marine Engineering: Propeller shafts, fasteners, and hull components in saltwater environments.

Automotive: High-performance racing components and exhaust systems.

Oil & Gas: Downhole tools and processing equipment in corrosive environments.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard Sizes Available

- square sizes: customized

- Standard lengths: 1000mm, 2000mm, 3000mm

- Custom lengths available upon request

Dimensional Tolerances:

- size tolerance: ±0.1mm to ±0.5mm depending on size

- Length tolerance: +10mm/-0mm

- Straightness: 1mm per meter maximum

Surface Finish:

- As-machined: Ra 3.2μm

- Polished finish available upon request

Quality Assurance and Testing

Every batch undergoes rigorous quality control:

Chemical Analysis: Spectroscopic verification of composition

Mechanical Testing: Tensile and hardness testing per ASTM standards

Dimensional Inspection: Precision measurement of all critical dimensions

Surface Quality Check: Visual and microscopic examination

Ultrasonic Testing: Internal defect detection when required

We maintain ISO 9001:2015 certification and follow aerospace quality standards. All products ship with certified test reports documenting compliance with specifications.

|

|

|

OEM & Customization Services

We understand that every application has unique requirements. Our technical team works closely with you to develop custom solutions. Services include:

- Custom dimensions and tolerances

- Special heat treatments

- Surface modifications

- Machined components from square rod stock

- Small quantity prototyping

- Large volume production runs

Packaging and Shipping

Your order receives careful packaging to prevent damage during transit:

Standard Packaging: Wooden crates with foam protection for international shipping

Documentation: Complete paperwork including certificates, packing lists, and shipping documents

Delivery Options: Express courier, air freight, or sea freight depending on urgency and destination

Tracking: Full shipment tracking from our facility to your door

|

|

|

|

|

|

|

|

|

|

|

|

Cooperation process

1. inquiry and quotation according to your request

2. Proforma invoice receive 30% deposit

3. Production may need about 7-20days

4. Packing and delivery after received your balance payment

5. Customer receiving the products and after-sale service

Payment term: 30% TT in advance and 70% balance payment before shipping

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of rare metal experience to every order. Located in China's "Titanium Capital," we have direct access to premium raw materials and advanced processing facilities.

Our commitment to quality and customer satisfaction has earned trust from clients in over 50 countries. We combine competitive pricing with reliable delivery and technical support. Whether you need standard sizes or custom solutions, our team delivers excellence every time.

|

|

|

|

|

|

FAQs

Q: What's the difference between Grade 1 and Grade 2 titanium?

A: Grade 2 offers higher strength while maintaining excellent corrosion resistance and formability compared to Grade 1.

Q: Can you provide smaller quantities for prototyping?

A: Yes, we accommodate both small prototype orders and large production volumes.

Q: What certifications do your products carry?

A: All products include material certificates per ASTM B348 with complete chemical and mechanical test results.

Q: Do you offer machining services?

A: Yes, we can machine finished components from our square rod stock to your specifications.

Contact Us

Ready to discuss your gr2 titanium square rod requirements? Our technical team stands ready to help you selsquareect the right material and specifications for your application.

Email: info@chdymetal.com

Contact us today for competitive pricing, technical specifications, or custom solutions. We look forward to becoming your trusted partner for premium titanium materials.

Learn about our latest products and discounts through SMS or email