- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

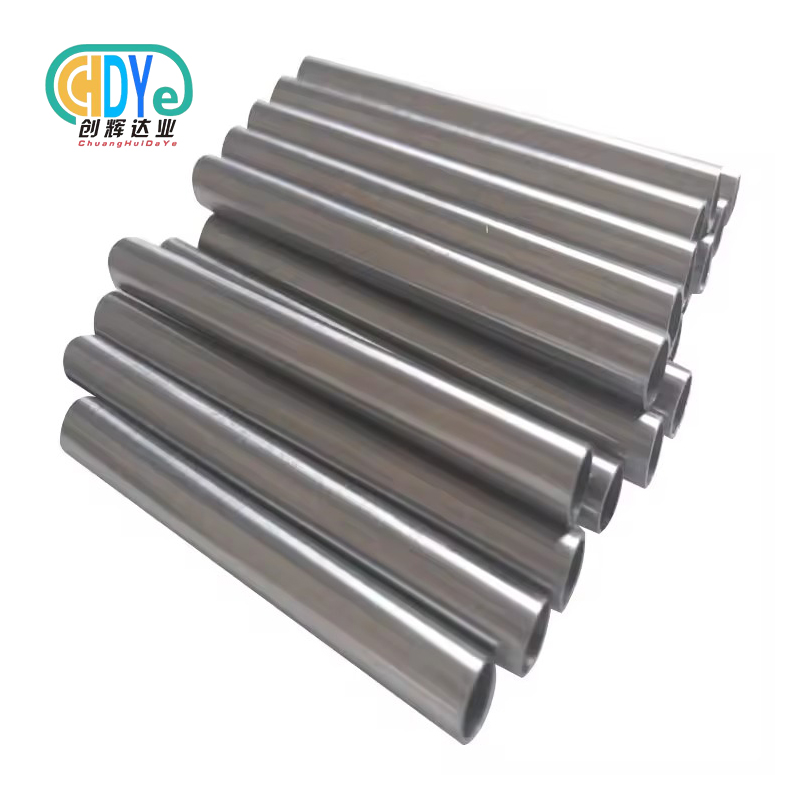

gr23 titanium bar

2. Diameter: 4mm – 20mm

3. Length: 2500- 3000mm

4. Tolerance: h7, h8, h9

Product Introduction

Looking for superior medical-grade titanium? Our gr23 titanium bar delivers exceptional performance for your most demanding applications. Ti-6Al-4V ELI (Extra Low Interstitial) represents the highest purity version of the popular Ti-6Al-4V alloy. This enhanced composition provides maximum toughness and reliability. You'll find this grade perfect for seawater environments, low-temperature applications, and critical medical implant manufacturing. The carefully controlled interstitial elements create outstanding mechanical properties that exceed standard titanium grades.

Key Features and Benefits

Superior Corrosion Resistance

- Excellent resistance to body fluids and harsh environments

- Outstanding performance in chlorine, fluorine, and hydrogen-based corrosive atmospheres

- Long-lasting durability in marine and chemical processing applications

Enhanced Mechanical Properties

- High strength-to-weight ratio for optimal performance

- Excellent toughness over wide temperature ranges

- Superior fatigue resistance for demanding cyclic loading

Biocompatibility Excellence

- Non-toxic and non-magnetic properties

- Perfect compatibility with human tissue

- FDA-approved for medical implant applications

Technical Specifications

Gr23 chemical composition

| Grade | C % max | O %max | N %max | Fe %max | H % max | Al % | V % |

| Gr23 | 0.08 | 0.13 | 0.05 | 0.25 | 0.015 | 6 | 4 |

Gr23 Physical properties

| Property | Value |

| Tensile Strength | 130,000 psi (minimum) |

| Yield Strength | 120,000 psi (minimum) |

| Elongation | 10% (minimum) |

| Density | 4.43 g/cm³ |

| Melting Point | 1604-1660°C |

| Young's Modulus | 114 GPa |

Available Grades and Materials

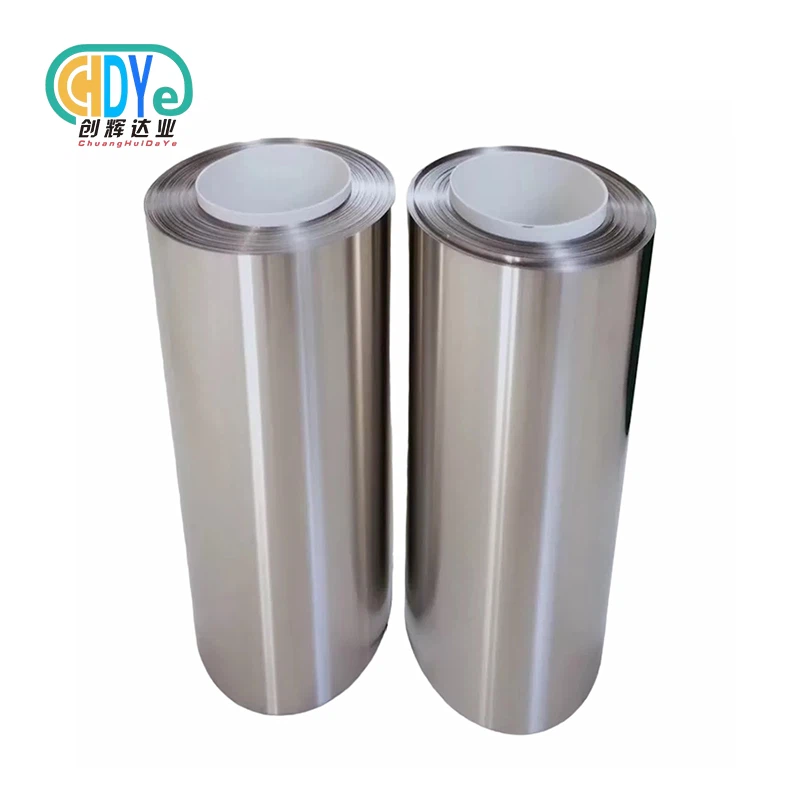

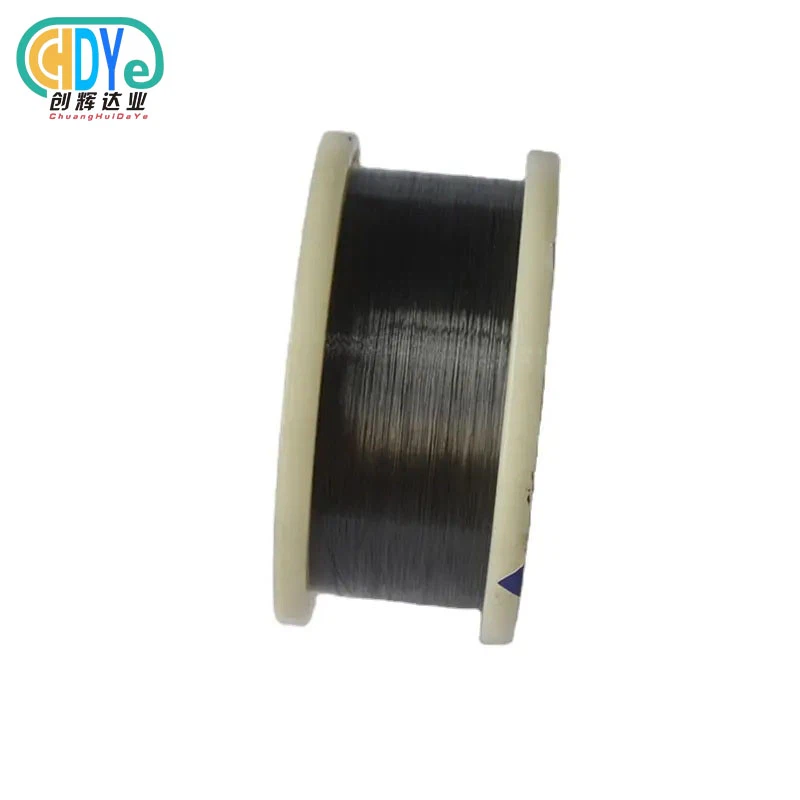

We specialize in gr23 titanium bar production with various surface finishes:

- Hot-rolled and annealed condition

- Cold-drawn with bright finish

- Pickled surface treatment

- Polished to mirror finish

All materials comply with ASTM B348 and ASTM F136 specifications.

Manufacturing Process

Our advanced production facility utilizes state-of-the-art techniques:

Vacuum Arc Remelting (VAR)

Multiple remelting cycles ensure chemical homogeneity and eliminate inclusions.

Hot Forging and Rolling

Precision temperature control optimizes grain structure and mechanical properties.

Heat Treatment

Carefully controlled annealing processes maximize toughness and stress relief.

Quality Control

Every bar undergoes comprehensive testing including ultrasonic inspection and dimensional verification.

|

|

|

|

|

|

|

|

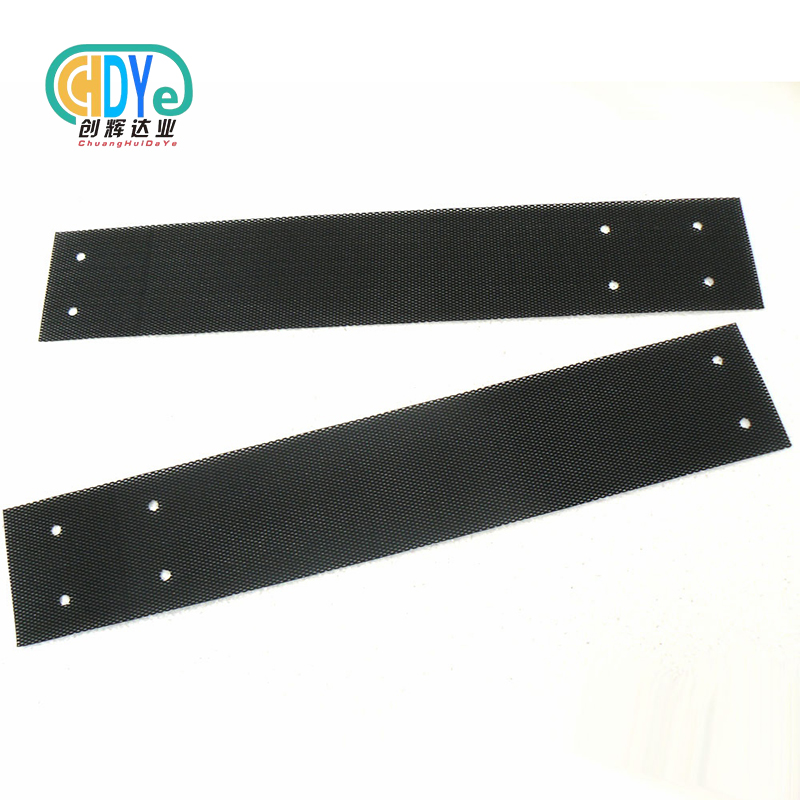

Applications and Industries

Medical and Dental

- Orthopedic implants and prosthetics

- Dental implants and surgical instruments

- Cardiovascular devices

Aerospace and Defense

- Aircraft structural components

- Engine parts requiring high temperature resistance

- Military applications demanding reliability

Marine and Chemical Processing

- Seawater heat exchangers

- Chemical processing equipment

- Offshore platform components

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard Sizes Available:

- Diameter: 6mm to 300mm

- Length: Up to 6000mm

- Tolerance: ±0.1mm to ±0.5mm (depending on diameter)

Custom Dimensions:

We accommodate special size requirements based on your specifications.

Product Features in Detail

The gr23 titanium bar offers unmatched performance characteristics. Its extra low interstitial content provides enhanced fracture toughness compared to standard Grade 5 titanium. You'll appreciate the improved ductility at cryogenic temperatures, making it ideal for extreme environment applications. The controlled chemistry ensures consistent mechanical properties throughout the entire bar length.

Quality Assurance and Testing

Comprehensive Testing Protocol:

- Chemical composition analysis

- Mechanical property verification

- Ultrasonic flaw detection

- Dimensional inspection

- Surface quality assessment

Certifications:

- Mill Test Certificate provided with every shipment

- Traceability documentation for full material history

- ISO 9001:2015 quality management system

|

|

OEM & Customization Services

Our experienced team provides tailored solutions for your specific requirements:

- Custom alloy compositions

- Specialized heat treatments

- Unique surface finishes

- Non-standard dimensions

- Technical consultation and support

Packaging and Shipping

Protective Packaging:

- Individual bar protection with foam wrapping

- Wooden crates for international shipping

- Moisture-resistant packaging materials

- Clear identification labeling

|

|

|

|

|

|

|

|

|

|

|

|

Global Shipping:

We deliver worldwide with reliable logistics partners ensuring safe arrival of your gr23 titanium bar orders.

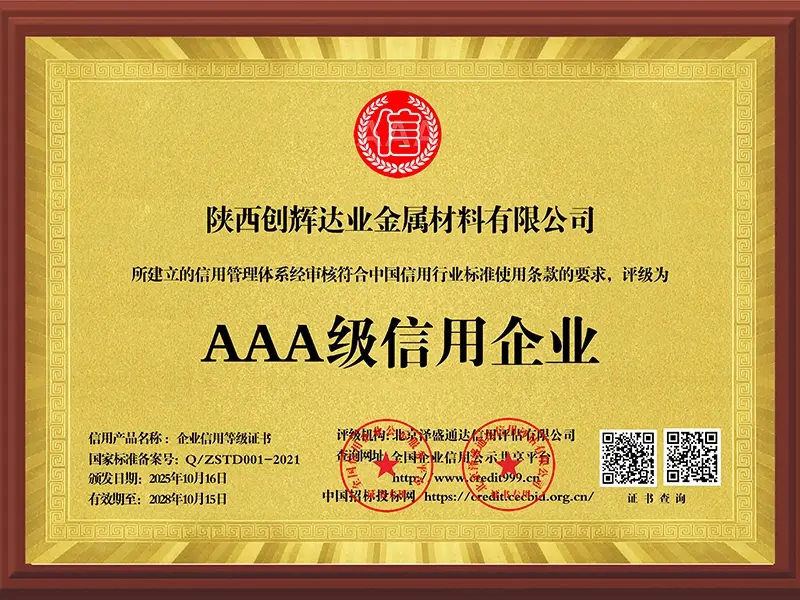

Why Choose Us

With over 30 years of rare metal industry experience, Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as your trusted partner. Located in China's "Titanium Capital," we combine advanced manufacturing capabilities with deep technical expertise. Our commitment to quality and customer satisfaction has earned trust from clients across 50+ countries.

Our Advantages:

- Extensive inventory for quick delivery

- Competitive pricing with no compromise on quality

- Technical support throughout your project

- Flexible packaging options

- Comprehensive after-sales service

|

|

|

|

|

|

FAQs

Q: What makes GR23 different from standard Ti-6Al-4V?

A: GR23 features extra low interstitial elements, providing enhanced toughness and biocompatibility.

Q: Can you provide custom lengths?

A: Yes, we offer cutting services to your exact specifications.

Q: What's the typical lead time?

A: Standard sizes ship within 5-7 days. Custom orders require 2-3 weeks.

Q: Do you provide material certificates?

A: Every shipment includes comprehensive mill test certificates.

Contact Us

Ready to discuss your gr23 titanium bar requirements? Our technical team stands ready to assist with material selection, specifications, and custom solutions.

Email: info@chdymetal.com

Let us help you find the perfect titanium solution for your application. Contact us today for competitive pricing and expert guidance.

Learn about our latest products and discounts through SMS or email