- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

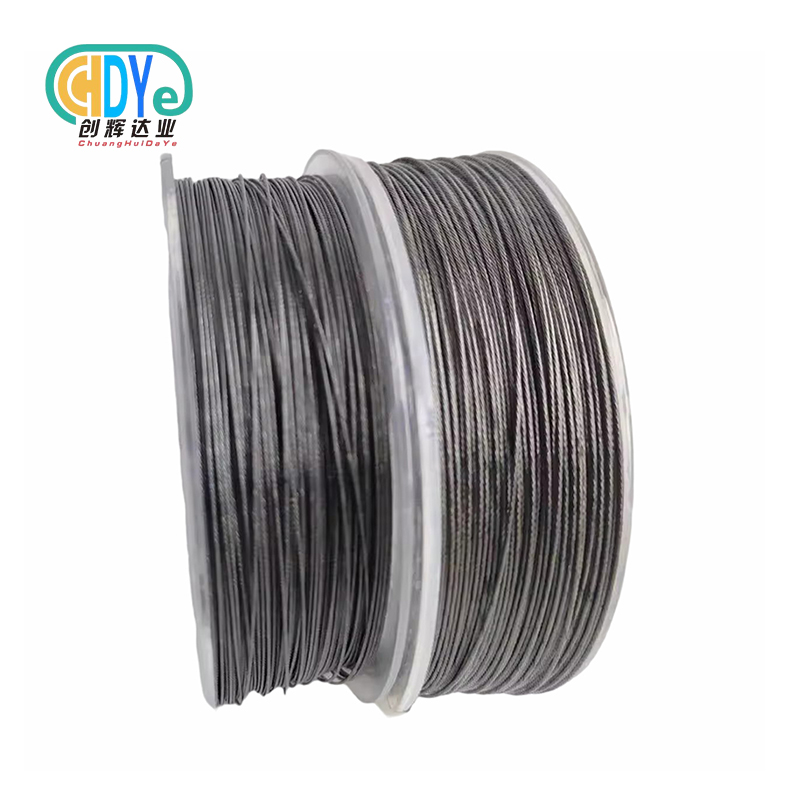

ASTM B 387 Molybdenum Wire

2.Density:10.2g/cm3

3.Feature:high melting point, high strength, high hardness and good electrical conductivity

Product Introduction

The ASTM B 387 Molybdenum Wire supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-performance product designed for demanding applications requiring exceptional strength, conductivity, and heat resistance. Manufactured strictly in accordance with ASTM B387 standards, this wire features high purity, uniform grain structure, and outstanding dimensional precision. With a melting point above 2600°C and excellent resistance to oxidation and corrosion, the wire is widely used in industries such as electronics, lighting, and metallurgical processing. Our ASTM B 387 Molybdenum Wire ensures reliable performance under extreme environments, making it the preferred choice for global clients seeking premium quality molybdenum materials.

The main properties of molybdenum wire include high melting point, high strength, high hardness and good electrical conductivity. These properties make molybdenum wire perform well under high temperature and heavy load conditions.Chdymetal offer various molybdenum wire size with competitive price and good quality.

|

Grade |

MO1, MO2 |

Production range: |

Diameter 0.10MM-1.0MM (can be customized according to customer requirements) |

|

Standards: |

ASTM B387-10 |

Melting point : |

2610 ℃ |

|

Purity: |

Pure molybdenum ≥99.95% |

Tensile strength of molybdenum wire: |

generally between 2500-3300Mpa |

|

Density: |

≥ 10.2g/cm3 |

Scope of application: |

Heating elements, high-temperature components, wire cutting, etc. |

Diameter specification:0.10mm, 0.11mm,0.12mm, 0.13mm, 0.15mm, 0.18mm, 0.20mm, 0.25mm, 0.28mm, 0.30mm, 0.32mm, 0.35mm, 0.38mm, 0.40mm, 0.45mm, 0.50mm, 0.55mm, 0.60mm, 0.70mm, 0.80mm, 0.90mm, 1.0mm and customized

Advantage:

1.Molybdenum wire high pricision,line diameter tolerance control at less than 0 to 0.002mm

2.The ratio of breaking wire low,processing rate is high,good performance and good price.

3.Can finish the stable long time continuous processing.

Application Advantages

Molybdenum materials are mainly used in vacuum high-temperature industries, electronics industries, sapphire thermal fields, and aerospace manufacturing industries. After rolling processing with a deformation of more than 60%, the density of molybdenum is basically close to the theoretical density. Therefore, it has high strength, uniform internal structure, and excellent high-temperature creep resistance

1. Pure molybdenum wire is used for filament winding core wire, lighting bulb bracket, lighting bulb lead out wire, electrical heating element, molybdenum foil strip, wire cutting, automotive parts spraying and other products.

2. High temperature molybdenum wire is used for filament winding core wire, lighting bulb glass sealing parts, molybdenum foil strips, furnace heating materials, wire cutting, high-temperature components, electronic tube springs, grids, and other products.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production process of ASTM B 387 Molybdenum Wire involves advanced techniques to ensure consistent quality and performance:

- Raw Material Selection: High-purity molybdenum powder is screened to meet ASTM standards.

- Pressing & Sintering: The powder is cold isostatically pressed and sintered in a hydrogen furnace for dense structure formation.

- Hot Rolling & Forging: The sintered billet undergoes rolling and forging to improve mechanical properties.

- Drawing Process: Multi-stage drawing ensures smooth surface finish and precise diameter tolerance.

- Annealing: Controlled atmosphere annealing relieves stress and enhances ductility.

- Final Inspection & Packaging: Strict testing guarantees that every wire meets customer and ASTM B387 specifications.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is the foundation of our production process. Each batch of ASTM B 387 Molybdenum Wire undergoes thorough testing and inspection including:

- Chemical Composition Analysis (to verify purity levels above 99.95%)

- Tensile Strength & Elongation Tests (to ensure ductility and resilience)

- Dimensional Accuracy Verification (using laser measurement systems)

- Surface Quality Inspection (checking for defects, cracks, or inclusions)

Our ISO 9001:2015-certified quality management system ensures that every wire delivered meets global industrial standards.

R&D and Customization

Shaanxi Chuanghui Daye Metal Material Co., Ltd. maintains a strong R&D team dedicated to developing innovative solutions for molybdenum products. Our research focuses on high-purity refining, surface coating, and advanced alloying to improve oxidation resistance and machinability. Clients can request customized ASTM B 387 Molybdenum Wire in various diameters, lengths, and surface finishes, including polished, cleaned, or chemically treated options. We also support prototype development, small-batch production, and specialized wire grades for emerging technologies.

Packaging & Global Logistics

To ensure product integrity during transportation, ASTM B 387 Molybdenum Wire is packaged with care and precision:

- Inner Packaging: Vacuum-sealed or anti-rust film wrapping.

- Outer Packaging: Foam padding and export-grade wooden boxes.

- Labeling: Clear identification of product specifications, batch number, and production date.

Our logistics network supports reliable air, sea, and land transportation, ensuring on-time delivery to over 50 countries worldwide. Each shipment complies with international export standards for safety and durability.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer comprehensive OEM and ODM services tailored to customers’ specifications. From material selection to technical drawing and surface treatment, our engineers work closely with clients to develop customized ASTM B 387 Molybdenum Wire solutions. Services include:

- Custom dimensions and tolerance adjustments

- Prototyping and mass production

- Third-party inspection arrangement

- After-sales technical consultation

With professional support and flexible production capabilities, we help clients reduce lead time and cost while ensuring superior product consistency.

Inspection Process

Every stage of ASTM B 387 Molybdenum Wire production is subject to strict inspection protocols:

- Incoming Material Inspection: Verify purity and chemical composition.

- Process Inspection: Continuous monitoring during sintering and drawing.

- Final Quality Check: Dimensional precision, tensile strength, and visual appearance.

- Packaging Review: Ensuring safe and compliant export packaging.

Our team ensures that no defective material enters the market, maintaining 100% quality assurance.

Why Choose Us

- 30+ Years of Expertise: Decades of experience in rare metal production and processing.

- ISO 9001:2015 Certified: Ensures consistent quality management and process control.

- Comprehensive Customization: Tailored solutions for various industries and technical standards.

- Fast Global Delivery: 7-day standard delivery with stable supply capacity.

- Trusted Worldwide: Exported to over 50 countries with excellent customer satisfaction.

Choosing Shaanxi Chuanghui Daye means partnering with a reliable, innovative, and customer-oriented molybdenum wire manufacturer.

|

|

|

|

|

|

FAQs

Q1: What is the purity of the ASTM B 387 Molybdenum Wire?

A1: The typical purity is ≥99.95%, ensuring excellent performance in high-temperature and vacuum environments.

Q2: Can you provide customized diameters or wire lengths?

A2: Yes, we can produce molybdenum wire from 0.05 mm up to 3 mm in diameter, with lengths tailored to your needs.

Q3: What surface finishes are available?

A3: We offer black (as-drawn), cleaned, and polished finishes depending on the application.

Q4: How long is the delivery time?

A4: Standard orders are shipped within 7–10 days, with expedited options available for urgent requirements.

Q5: Do you support international shipping?

A5: Yes, we provide reliable air, sea, and courier logistics services to all major global markets.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email