- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

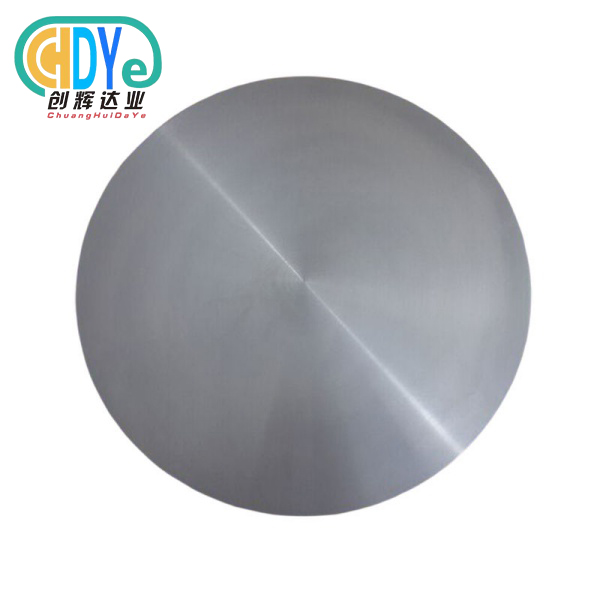

Looking for reliable gr4 titanium bar solutions for your demanding applications? You've come to the right place. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we specialize in manufacturing high-quality Grade 4 titanium bars that deliver exceptional strength and corrosion resistance. Our titanium bars meet international standards and serve industries worldwide with proven reliability and performance.

Product Introduction

Grade 4 titanium bars represent the strongest commercially pure titanium available in the market. These bars offer superior mechanical properties compared to lower titanium grades while maintaining excellent corrosion resistance. Our manufacturing facility in Baoji, China's "Titanium Capital," ensures consistent quality and competitive pricing for all your titanium needs.

Chemical composition:

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Key Features and Benefits

- Superior Strength: Highest strength among pure titanium grades

- Excellent Corrosion Resistance: Withstands harsh chemical environments

- Lightweight Design: Lower density than stainless steel alternatives

- Outstanding Ductility: Easy to form and machine

- Temperature Resistant: Maintains properties at elevated temperatures

- Biocompatible: Safe for medical and food processing applications

Technical Specifications

Our gr4 titanium bar products comply with multiple international standards:

- Standards: ASTM B348, ASME SB348, ASTM F-67,

- Grade: UNS R50700 (Werkstoff Nr. 3.7065)

- Diameter Range: 6.0mm - 200mm

- Length: 1000mm - 6000mm (standard 2000mm - 5800mm)

- Tensile Strength: 550 MPa minimum

- Yield Strength: 480 MPa minimum

- Elongation: 15% minimum

Available Grades and Materials

We offer comprehensive titanium solutions beyond Grade 4:

- Commercially Pure Titanium (Grades 1-4)

- Titanium Alloys (Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo)

- Custom alloy compositions upon request

The application of various grade Titanium description

(1).Grade 1 can be used in the drawing parts for its good elongation and excellent corrosion-resistance.

(2).Grade 2 is used most widely in the commercially pure titanium

(3).Grade 3 is almost used in pressure,vessel.

(4).Grade 4 can be used in some fittings parts and fastening pieces, but for complex shape need 300 degree Celsius to form.

(5).Alloy grade 5 widely used in the titanium alloys because of its comprehensive mechanical and

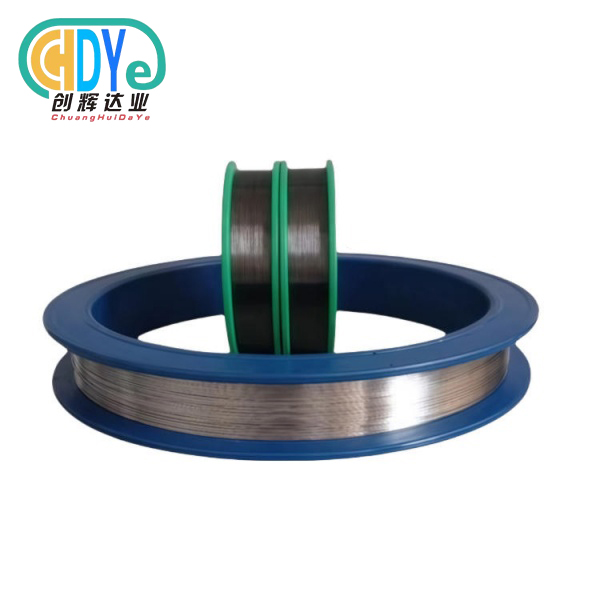

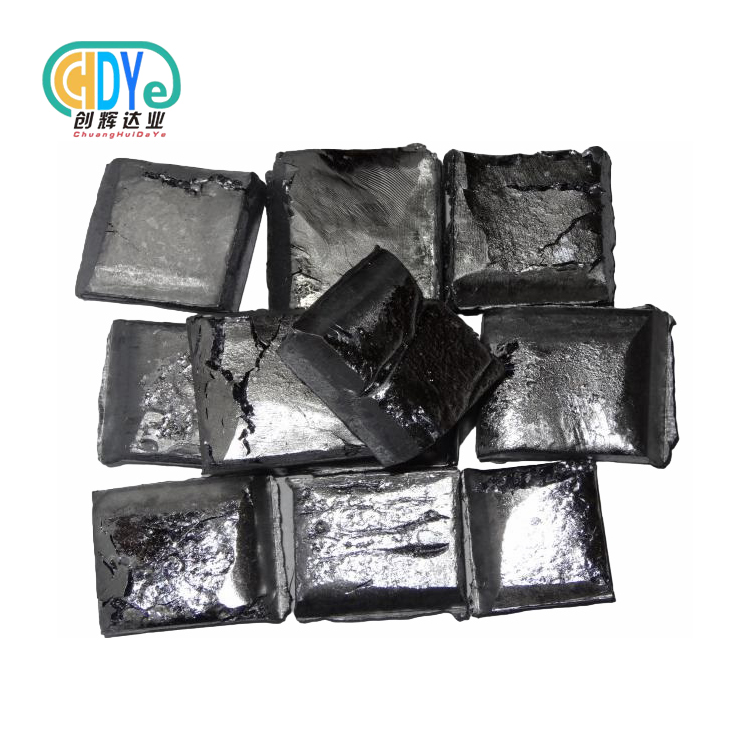

Manufacturing Process

Our state-of-the-art manufacturing process ensures consistent quality:

- Raw Material Selection: Premium titanium sponge sourcing

- Vacuum Arc Remelting: Creates homogeneous material structure

- Hot Rolling: Achieves desired mechanical properties

- Heat Treatment: Stress relief and annealing processes

- Precision Machining: Meets exact dimensional requirements

- Quality Testing: Comprehensive inspection protocols

|

|

|

|

|

|

|

|

Applications and Industries

GR4 titanium bar finds extensive use across multiple sectors:

- Chemical Processing: Reactors, heat exchangers, piping systems

- Marine Industry: Offshore platforms, desalination plants

- Aerospace: Structural components, fasteners

- Medical Devices: Surgical instruments, implants

- Automotive: High-performance racing applications

- Oil & Gas: Downhole equipment, refineries

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional control for optimal performance:

- Diameter Tolerance: ±0.1mm to ±0.5mm

- Length Tolerance: +0/-5mm

- Straightness: 1.5mm per meter maximum

- Surface Finish: Ra 1.6μm or better

- Roundness: Within 0.1mm

Product Features in Detail

Our titanium bars undergo specialized processing for enhanced performance. The cold drawing process improves surface finish and dimensional accuracy. Heat treatment ensures optimal microstructure and mechanical properties. Each bar receives individual inspection to guarantee conformance to specifications.

Quality Assurance and Testing

Every gr4 titanium bar undergoes rigorous testing:

- Chemical composition analysis

- Mechanical property testing

- Ultrasonic inspection

- Dimensional verification

- Surface quality assessment

- Material traceability documentation

|

|

|

OEM & Customization Services

We provide tailored solutions for your specific requirements:

- Custom diameters and lengths

- Special surface finishes

- Unique packaging requirements

- Technical consultation services

- Rapid prototyping capabilities

Packaging and Shipping

Your products arrive safely with our professional packaging:

- Protective wrapping prevents surface damage

- Wooden crates for international shipping

- Complete documentation package

- Worldwide delivery capabilities

- Express shipping options available

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of rare metal industry experience, we offer:

- Competitive pricing from direct manufacturer

- Consistent quality control systems

- Global shipping to 50+ countries

- Technical support and consultation

- Flexible order quantities

- On-time delivery guarantee

|

|

|

|

|

|

FAQs

Q: What makes Grade 4 different from other titanium grades?

A: Grade 4 offers the highest strength among commercially pure titanium while maintaining excellent corrosion resistance and formability.

Q: Can you provide material certificates?

A: Yes, we provide complete material test certificates with chemical composition and mechanical properties for every order.

Q: What's your minimum order quantity?

A: We accommodate both small prototype orders and large production runs based on your needs.

Q: Do you offer machining services?

A: We provide precision machining services to deliver finished components ready for your application.

Contact Us

Ready to discuss your titanium requirements? Our experienced team is here to help you find the perfect solution. Whether you need standard sizes or custom specifications, we'll work with you to meet your exact needs.

Email: info@chdymetal.com

Mob/what'sapp: 86-18049386902

Get your quote today and experience the difference that quality makes. Trust Shaanxi Chuanghui Daye Metal Material Co., Ltd. for all your gr4 titanium bar requirements.

Learn about our latest products and discounts through SMS or email