- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

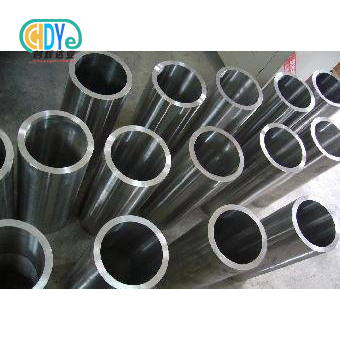

niobium targets

2.Density: 8.5 g/cm3

3.Standard: ASTM B 392

4.Size: Dia ≥ 5 mm * Thick ≥ 0.1 mm

5. Surface: cold rolled surface / Machined surface

Niobium Targets

Looking for reliable niobium targets for your sputtering applications? Our premium niobium targets deliver exceptional purity of 99.95% and superior performance for superconducting coating systems. With over 30 years of expertise in rare metal manufacturing, Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides you with top-quality sputtering materials that meet the most demanding industrial requirements. Our targets feature uniform density distribution and precise dimensional tolerances for optimal coating results.

Key Features and Benefits

Our niobium sputtering targets offer outstanding performance characteristics that make them ideal for your critical applications. You'll benefit from excellent corrosion resistance that withstands acids and alkalis. The high melting point of 2,477°C ensures stability in extreme temperature environments. Our materials provide superior chemical stability with minimal grain boundary diffusion during extended use.

Technical Specifications

| Property | Value | |

|---|---|---|

| Purity | ≥99.9% | |

| Density | 8.5g/cm³ | |

| Theoretical Density | ≥99.8% | |

| Hardness | 95-130HV | |

| Metallic Impurities | ≤150ppm | |

| Nitrogen Content | ≤40ppm | |

| Thermal Conductivity | 54W/m·K | |

| Flatness Tolerance | ≤0.05mm | |

| Standard | ASTM B365 | |

| Surface treatment | Bright surface | |

| Certificate | ISO9001:2015 | |

| Delivery time |

production time need about 10- 15 working days. |

|

| Payment terms | 30% TT in advance, 70% balance before payment. | |

Chemical composition

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01

|

Mechanical Properties

|

Grade |

Tensile strength psi(MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

|

>=0.010 |

<0.010 |

|||

|

RO4200 RO4210 |

18000 (125) |

12000 (85) |

25 |

20 |

Available Grades and Materials

We supply niobium targets in industry-standard grades R04200 and R04210, manufactured according to ASTM B 392 specifications. These grades ensure consistent quality and performance across different applications. Our materials meet stringent purity requirements for semiconductor and electronic device manufacturing.

Manufacturing Process

Our advanced manufacturing process combines precision machining with strict quality control. We use high-purity niobium feedstock and employ specialized techniques to achieve uniform microstructure. Cold rolling and precision machining create smooth surfaces that optimize plasma distribution during sputtering operations.

|

|

|

|

|

|

|

|

Applications and Industries

Semiconductor Industry: Essential for chip manufacturing through physical vapor deposition processes. Your devices benefit from controlled thin film composition and thickness.

Electronic Components: Perfect for LCD manufacturing where transparent conductive layers are required on glass substrates.

Energy Sector: Solar panel production utilizes our targets for improved conversion efficiency and long-term stability.

Medical Devices: Biocompatible properties make them suitable for dental implants and other medical applications.

Research Applications: Universities and laboratories use our targets for developing new materials and superconducting research.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

| Specification | Range |

|---|---|

| Diameter | ≥5 mm |

| Thickness | 3-25 mm (standard) |

| Minimum Thickness | 0.1 mm |

| Custom Sizes | Available upon request |

Quality Assurance and Testing

Every batch undergoes comprehensive testing including purity analysis, density measurement, and surface quality inspection. We verify mechanical properties and ensure compliance with international standards. Our quality management system guarantees consistent product performance.

|

|

|

OEM & Customization Services

We understand that your applications may require specific dimensions or properties. Our engineering team works closely with you to develop customized solutions. From unique geometries to specialized surface treatments, we adapt our niobium targets to meet your exact requirements.

Packaging and Shipping

Your targets are carefully packaged in protective materials to prevent contamination and damage during transport. We use vacuum-sealed packaging when required and provide detailed documentation with each shipment. Our logistics team ensures safe delivery to over 50 countries worldwide.

Why Choose Us

With three decades of rare metal expertise, we bring unmatched knowledge to every project. Our location in China's "Titanium Capital" provides access to premium raw materials and advanced manufacturing facilities. You receive competitive pricing, on-time delivery, and dedicated customer support throughout your project lifecycle.

|

|

|

|

|

|

Product Features in Detail

Our niobium targets feature exceptional uniformity that ensures consistent coating thickness across your substrate. The fine grain structure promotes stable plasma formation and reduces particle generation during sputtering. Low gas content prevents contamination of your deposited films, while excellent thermal conductivity maintains stable processing temperatures.

FAQs

Q: What purity levels are available for niobium targets?

A: We supply targets with purity levels of 99.95% and higher, suitable for most industrial applications.

Q: Can you provide custom dimensions?

A: Yes, we manufacture targets according to your specific size requirements and chamber configurations.

Q: What is the typical lead time for orders?

A: Standard products ship within 1-2 weeks, while custom orders may require 2-3 weeks depending on specifications.

Q: Do you provide technical support?

A: Our experienced team offers comprehensive technical assistance for material selection and application guidance.

Contact Us

Ready to enhance your coating processes with premium niobium targets? Contact our technical team today to discuss your specific requirements. We're here to help you achieve optimal results in your sputtering applications.

Email: info@chdymetal.com

Mob./what's app.: 86-18049386902

Learn about our latest products and discounts through SMS or email