- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

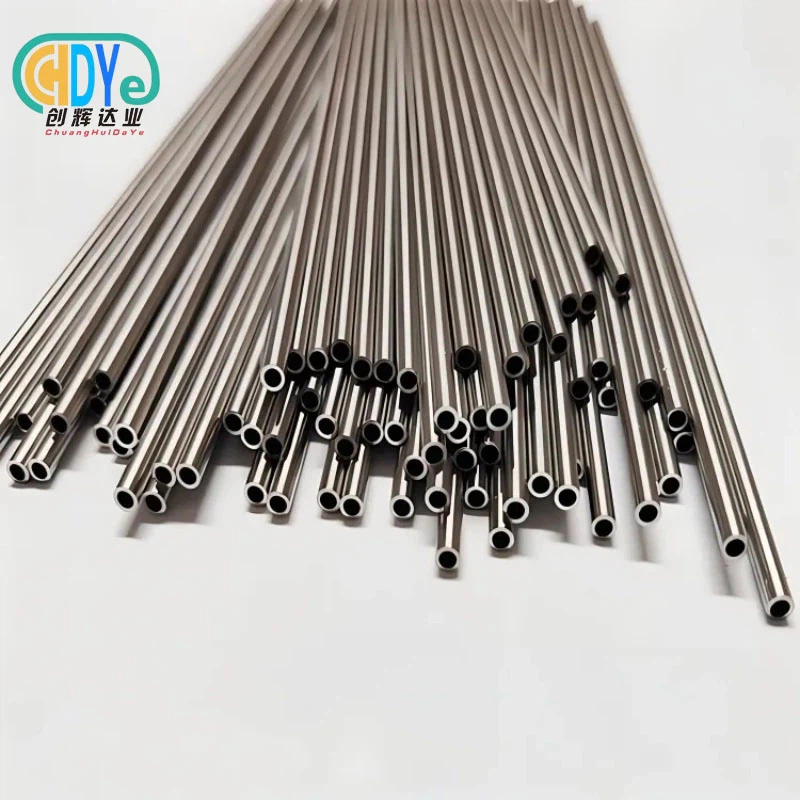

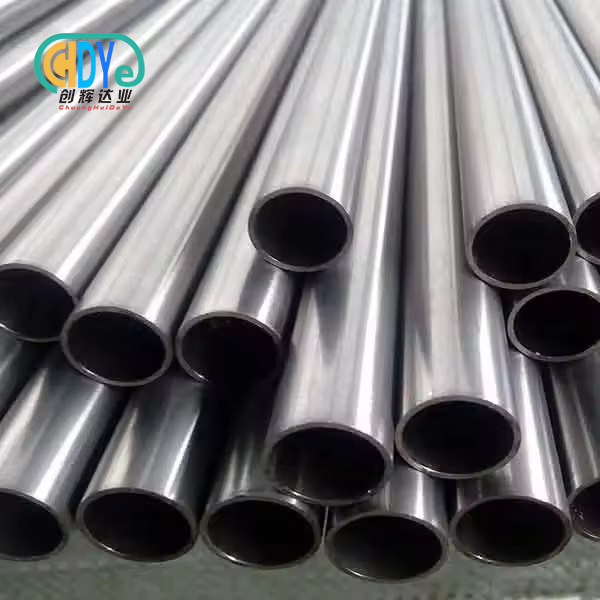

niobium sheet plate

2. Standard: ASTM B393

3. Surface: Polished, annealed, Cold-rolled bright

Product Introduction

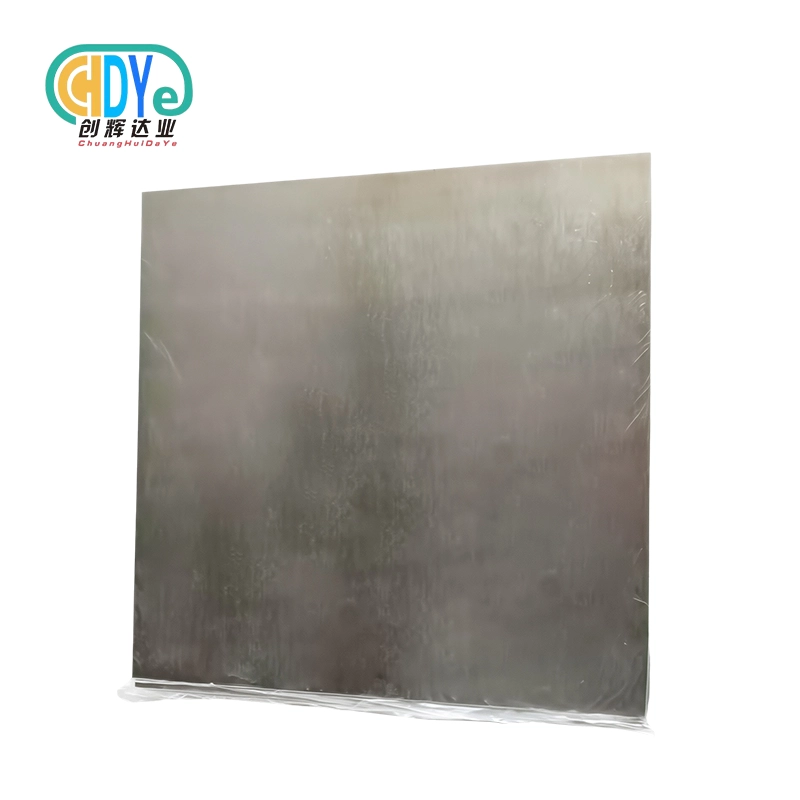

Looking for reliable niobium sheet plate for your industrial applications? You've come to the right place. Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers premium quality niobium sheets that meet the most demanding requirements across electronics, chemical processing, and aerospace industries. Our advanced manufacturing capabilities ensure you receive consistent, high-purity material that performs exactly as expected. With over 30 years of experience in rare metal production, we understand what it takes to deliver exceptional products that drive your success forward.

Key Features and Benefits

Your projects deserve the best materials available. Our niobium sheets offer superior corrosion resistance, making them perfect for harsh chemical environments. The exceptional ductility and malleability allow for complex forming operations without cracking or failure. You'll appreciate the excellent thermal conductivity and low neutron capture cross-section properties. The material maintains stability across wide temperature ranges. These characteristics make our products ideal for superconducting applications and high-temperature environments.

Technical Specifications

| Property | Value |

|---|---|

| Purity | Nb >99.9% |

| Density | 8.57 g/cm³ |

| Thickness Range | 0.1–30 mm |

| Maximum Width | 500 mm |

| Maximum Length | 3000 mm |

| Melting Point | 2477°C |

| Surface Finish | Polished/As-rolled |

| Delivery Condition | Annealed |

| Grade | R04200, R04210, R04251, R04261 |

| Standard | ASTM B393 |

| Packing | Foam material inside, wooden box outside. |

| Payment terms | 30%TT in advance, 70% balance before shipment |

| Delivery time | Stock size will be arrange quick delivery within 1-3 days |

Plate Size

|

Thickness |

The allowable deviation thickness |

Width |

The allowable deviation Width |

Length |

|

|

Width>120~300 |

Width>300 |

||||

|

0.1~0.2 |

±0.015 |

±0.02 |

>300~420 |

±2.0 |

>100 |

|

>0.2~0.3 |

±0.02 |

±0.03 |

>200~420 |

±2.0 |

>100 |

|

>0.3~0.5 |

±0.03 |

±0.04 |

>200~420 |

±2.0 |

50~3000 |

|

>0.5~0.8 |

±0.04 |

±0.06 |

>200~420 |

±2.0(±5.0) |

50~3000 |

|

>0.8~1.0 |

±0.06 |

±0.08 |

>200~420 |

±2.0(±5.0) |

50~3000 |

|

>1.0~1.5 |

±0.08 |

±0.10 |

>200~420 |

±3.0(±5.0) |

50~3000 |

|

>1.5~2.0 |

±0.12 |

±0.14 |

>200~420 |

±3.0(±5.0) |

50~3000 |

|

>2.0~3.0 |

±0.16 |

±0.18 |

>200~420 |

±5.0 |

50~3000 |

|

>3.0~4.0 |

±0.18 |

±0.20 |

>200~420 |

±5.0 |

50~3000 |

|

>4.0~6.0 |

±0.20 |

±0.24 |

>200~420 |

±5.0 |

50~3000 |

Chemical composition

|

Niobium and Niobium Alloys Sheet Chemical Composition |

||||

|

Element |

Type1 (Reactor Grade Unalloyed Nb) R04200 |

Type2 (Commercial Grade Unalloyed Nb) R04210 |

Type3 (Reactor Grade Nb-1%Zr) R04251 |

Type4 (Commercial Grade Nb-1%Zr) R04261 |

|

Max Weight % (Except Where Otherwise Specified) |

||||

|

C |

0.01 |

0.01 |

0.01 |

0.01 |

|

N |

0.01 |

0.01 |

0.01 |

0.01 |

|

O |

0.015 |

0.025 |

0.015 |

0.025 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Zr |

0.02 |

0.02 |

0.8-1.2 |

0.8-1.2 |

|

Ta |

0.1 |

0.3 |

0.1 |

0.5 |

|

Fe |

0.005 |

0.01 |

0.005 |

0.01 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

W |

0.03 |

0.05 |

0.03 |

0.05 |

|

Ni |

0.005 |

0.005 |

0.005 |

0.005 |

|

Mo |

0.01 |

0.02 |

0.01 |

0.05 |

|

Hf |

0.02 |

0.02 |

0.02 |

0.02 |

|

Ti |

0.02 |

0.03 |

0.02 |

0.03 |

Available Grades and Materials

We supply pure niobium sheets meeting international standards. Our material maintains consistent purity levels above 99.9%. Various surface finishes are available to match your specific requirements. Custom compositions can be developed for specialized applications. All grades undergo rigorous quality testing before shipment.

Manufacturing Process

Our state-of-the-art production facility uses advanced vacuum melting techniques. The process begins with high-purity raw materials that undergo careful selection and preparation. Hot rolling operations create the initial sheet forms. Cold rolling achieves precise thickness tolerances. Annealing treatments optimize mechanical properties. Final inspection ensures every sheet meets your exact specifications.

|

|

|

|

|

|

|

|

Applications and Industries

The electronics industry relies on our niobium sheet plate for capacitor manufacturing and semiconductor applications. Chemical processing plants use these sheets for reactor vessels and heat exchangers. Aerospace companies incorporate them into engine components and structural elements. Medical equipment manufacturers choose our material for MRI machines and diagnostic equipment. Research facilities depend on these sheets for superconducting magnet construction.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard thickness tolerances are ±0.05mm for thin sheets and ±0.1mm for thicker materials. Width tolerances maintain ±2mm accuracy across the full range. Length cutting precision stays within ±5mm of specified dimensions. Custom sizing options are available for special applications. Edge finishing can be customized based on your requirements.

Product Features in Detail

You'll find our sheets exhibit excellent formability characteristics. The material responds well to bending, stamping, and deep drawing operations. Welding properties are outstanding when proper techniques are used. Surface quality remains consistent throughout the entire sheet. The material demonstrates excellent fatigue resistance under cyclic loading conditions. Temperature stability extends across a broad operating range.

Quality Assurance and Testing

Every batch undergoes comprehensive chemical analysis to verify composition. Mechanical property testing ensures strength and ductility meet specifications. Surface inspection eliminates defects before shipment. Dimensional verification confirms all measurements are within tolerance. Our quality management system follows international standards. Certificate of compliance accompanies every shipment.

|

|

|

OEM & Customization Services

We understand that your applications may require specific modifications to standard products. Our engineering team works closely with you to develop custom solutions. Special surface treatments can be applied when needed. Non-standard dimensions are readily available. Packaging can be customized for your handling requirements. Technical support continues throughout your project lifecycle.

Packaging and Shipping

Your niobium sheet plate arrives in protective packaging designed to prevent damage during transit. Individual sheets are separated with interleaving paper. Moisture barriers protect against environmental exposure. Wooden crates provide structural protection for larger shipments. We coordinate with reliable freight carriers to ensure timely delivery. Tracking information keeps you informed throughout the shipping process.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we bring over three decades of rare metal expertise to every project. Our founder's extensive industry experience ensures you receive knowledgeable guidance and superior products. We've successfully served customers in more than 50 countries worldwide. Our commitment to quality, competitive pricing, and customer satisfaction sets us apart from competitors. You can trust us to deliver exactly what you need, when you need it.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate orders of all sizes, from small prototype quantities to large production runs.

Q: Can you provide material certificates?

A: Yes, we provide complete chemical and mechanical property certificates with every shipment.

Q: What payment terms do you offer?

A: We accept various payment methods including T/T, L/C, and other arrangements based on order value.

Q: How long is the delivery time?

A: Standard products typically ship within 1-2weeks. Custom orders may require 2-3weeks depending on specifications.

Contact Us

Ready to discuss your niobium sheet plate requirements? Our technical team is standing by to help you select the perfect material for your application. Contact us today for detailed quotes, technical specifications, or custom solution development. We look forward to becoming your trusted partner for high-quality rare metal products.

E-mail : info@chdymetal.com

Mob./wht's app.: 86-18049386902

Learn about our latest products and discounts through SMS or email