- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

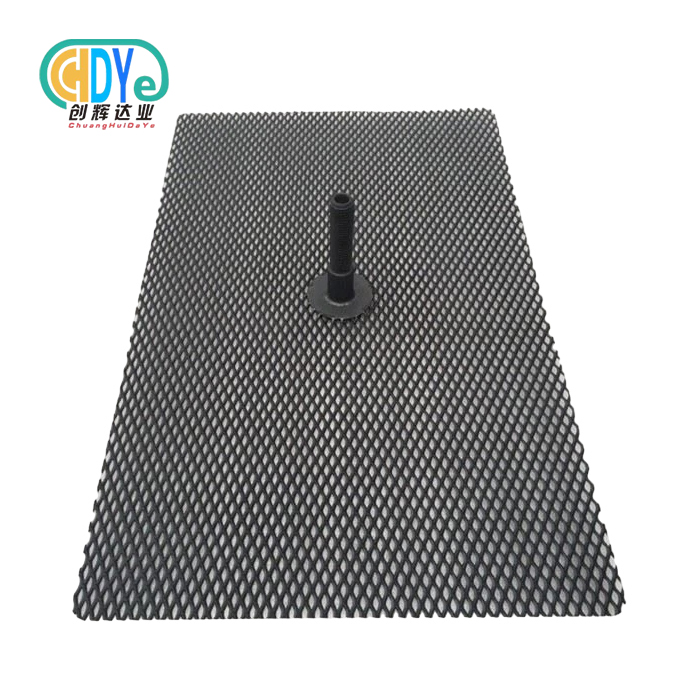

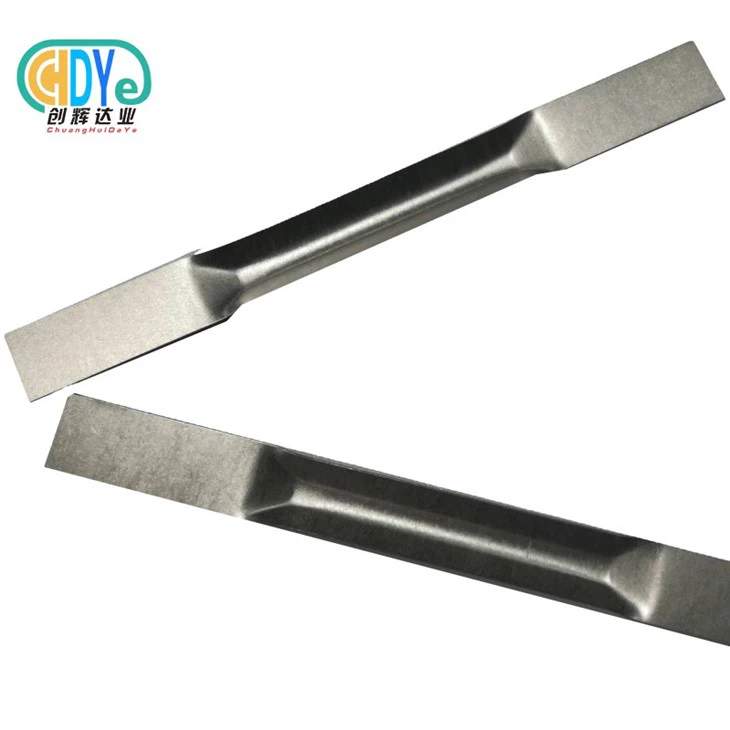

Medical Titanium Plate

Products Description

Titanium metal are light in weight, high in strength and superior in mechanical properties..It can be processed into various forms . medical titanium plate is one of our main products,the common grade use in medical industry is Gr 5, Gr 5 ELI, Gr23ELI.

Medical Titanium Plate is a precision-engineered titanium flat product designed specifically for surgical, dental, and orthopedic implant applications. Made from high-purity titanium and titanium alloys, these plates combine superior biocompatibility, mechanical strength, and corrosion resistance. They are widely used for bone fixation, cranial reconstruction, and prosthetic frameworks due to their light weight and excellent tissue compatibility.

Our medical titanium sheet are produced in compliance with ASTM F67 and ASTM F136 standards, ensuring consistent quality and traceability for every batch. Available in multiple thicknesses and customizable sizes, they are ideal for machining into orthopedic implants, bone plates, and dental structures.

|

Product name: |

Medical titanium plate |

|

Type: |

Gr 5, Gr 5 ELI, Ti-6Al-4V ELI, Gr23 |

|

Grade: |

Grade 1: Pure Titanium, relatively low strength and high ductility. |

|

Standard: |

ASTM F136, IS05832-3 |

|

Specification |

Hot Rolling: Length 1000-4000mm,Width 400-3000mm,Thickness 4.0-60mm |

|

delivery |

Customized 7-21 days, stock size 1-5days |

|

Price Terms: |

CIF CFR FOB EXW |

|

Payment Terms: |

T/T 30% deposit and 70% balance before shipment |

Chemcial Composition

|

Grade |

Ti |

Al |

V |

Fe, max |

C, max |

N, max |

H, max |

O, max |

|

Ti-6Al-4V ELI/Gr23 |

Bal |

5.5~6.5 |

3.5~4.5 |

0.25 |

0.08 |

0.05 |

0.012 |

0.13 |

|

Gr5 |

Bal |

5.5~6.5 |

3.5~4.5 |

0.30 |

0.08 |

0.05 |

0.015 |

0.20 |

Mechanical properties

|

Grade |

Tensile Strength (Rm/Mpa) ≥ |

Yield Strength (Rp0.2/Mpa) ≥ |

Elongation (A%) ≥ |

Reduction of Area (Z%) ≥ |

|

Ti-6Al-4V ELI/Gr23 |

860 |

795 |

10 |

25 |

|

Gr5 |

860 |

795 |

8 |

20 |

Medical titanium plate Inspection Process

1.Appearance and dimension inspection to ensure every titanium rod meets tolerances.

2. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

3. 100% Straightness inspection.

4. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Product Features and Benefits

- Excellent Biocompatibility – Non-toxic, non-allergenic, and perfectly compatible with human tissue.

- Superior Corrosion Resistance – Performs reliably in physiological environments such as saline or body fluids.

- Lightweight with High Strength – Offers excellent strength-to-weight ratio for medical device design.

- Custom Machinability – Can be precisely processed into implant components with tight dimensional accuracy.

- Compliance with Medical Standards – Manufactured under strict ISO 13485-certified processes to ensure patient safety.

Manufacturing & Processing Capability

Our advanced manufacturing line is equipped with vacuum melting furnaces, hot and cold rolling mills, precision surface treatment systems, and ultrasonic flaw detection. Each medical titanium plate undergoes precise rolling, annealing, straightening, and surface finishing to achieve uniform grain structure and mechanical consistency.

|

|

|

|

|

|

|

|

Quality Assurance

Strict quality control is implemented from raw material inspection to finished product testing. Each batch is tested for:

- Chemical composition analysis (ICP-OES)

- Mechanical property verification (tensile, yield, elongation)

- Ultrasonic flaw detection

- Surface roughness and flatness inspection

- Biocompatibility and cytotoxicity testing

Application Advantages

- Medical titanium plates are used extensively in the following areas:

- Orthopedic bone fixation plates and screws

- Craniofacial reconstruction implants

- Spinal fusion systems

- Dental implant bases and frameworks

- Cardiovascular device housings

- Surgical instruments requiring non-magnetic and lightweight material properties

R&D and Customization

Our R&D team cooperates with medical device manufacturers and research institutes to develop new titanium materials with optimized mechanical strength and biological activity. We provide customization for thickness, surface texture, and alloy composition to meet diverse implant design requirements.

We also support OEM/ODM projects, small-batch trials, and rapid prototype development to accelerate product innovation and market delivery.

Packaging & Logistics

Each medical titanium plate is individually wrapped with protective film, vacuum-packed, and securely placed in wooden or medical-grade export boxes.

We partner with international logistics providers to ensure fast and reliable delivery to hospitals, distributors, and implant manufacturers around the world.

|

|

|

|

|

|

|

|

|

|

|

|

Global Market & Cooperation

Our Medical Titanium Plate have been exported to over 50 countries, including the USA, Germany, France, South Korea, Mexico, and Singapore. We partner with distributors, manufacturers, and end-users worldwide, ensuring reliable supply and technical support for diverse industries.

Feedback from customers

Why Choose Us :

1. You can get the perfect material according to your requirement at the least possible price.

2. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

5. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Sample order is supported!

|

|

|

|

|

|

Medical Titanium Plate Transaction Process

1.First contact us to provide the grade, size ,quantity and standard or any special requirements.

2.we will reply you the quotation with delivery time in 3 hours.

3.reach an agreement then buyer arrange the prepayment.

4. when we get your payment we will arrange production asap and share you the production progress.

5.when production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment.

6. Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate.

8. Regular after-sales service to know the actual product usage.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Welcome to contact us for more information: info@chdymetal.com/ Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email