- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

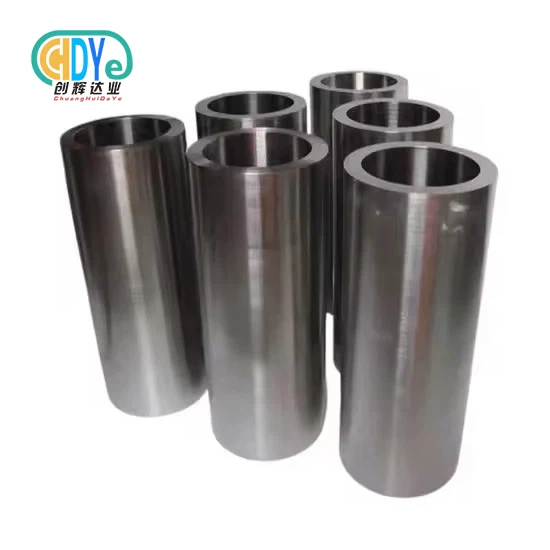

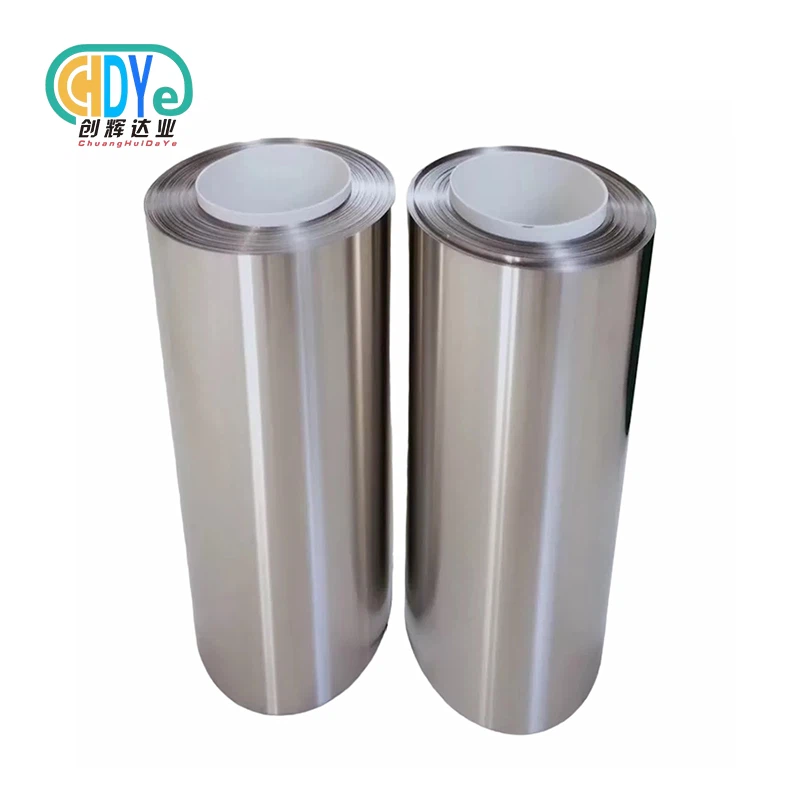

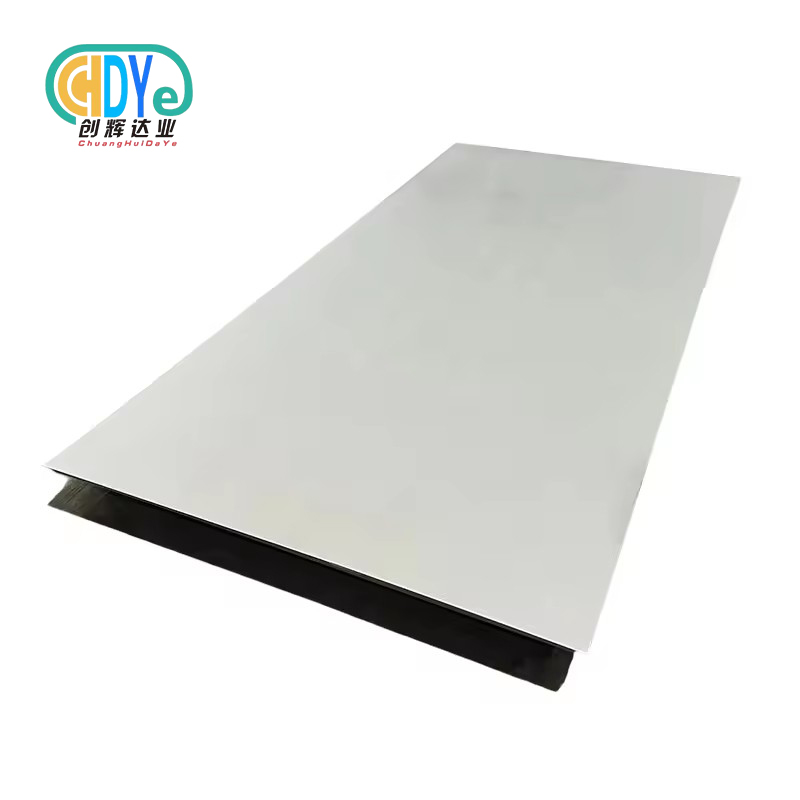

titanium 6al-4v plate

2. Thickness 1-50mm

3. Tensile strength 895-960 MPa

4. Density 4.43 g/cm³

5. Excellent corrosion resistance

6. Aerospace and marine use

7. High fatigue resistance

Product Introduction

When you need superior strength combined with lightweight properties, our titanium 6al-4v plate delivers exceptional performance for your critical applications. This Grade 5 titanium alloy contains 6% aluminum and 4% vanadium, creating an alpha-beta titanium alloy renowned for its balanced mechanical properties. Our plates offer tensile strength ranging from 895-960 MPa with a density of just 4.43 g/cm³, making them ideal for aerospace, medical, and industrial applications where performance cannot be compromised.

At Shaanxi Chuanghui Daye Metal Material, we leverage over 30 years of rare metal industry experience to provide you with premium quality plates that meet the most demanding specifications.

Key Features and Benefits

Superior Strength-to-Weight Ratio

You get maximum structural integrity without unnecessary weight, perfect for aerospace and automotive applications.

Exceptional Corrosion Resistance

Your components will withstand harsh environments, reducing maintenance costs and extending service life.

Outstanding Fatigue Resistance

Our plates endure cyclic stresses and repeated loading without degradation, ensuring long-term reliability.

Thermal Stability

The material maintains its mechanical properties up to 350°C, suitable for high-temperature environments.

Biocompatibility

Safe for medical implants and surgical instruments with excellent tissue compatibility.

Technical Specifications

- Alloy Composition: Ti-6Al-4V (Grade 5)

- Tensile Strength: 895-960 MPa

- Yield Strength: 828-896 MPa

- Density: 4.43 g/cm³

- Melting Point: 1604-1660°C

- Elastic Modulus: 114 GPa

- Elongation: 10-15%

titanium 6al-4v plate specification

|

Grade |

Gr5 (TI-6-Al-4V) |

|

Specification |

Thickness :0.5mm~50mm*Width:1000-3000mm |

|

Process method |

Cold rolling/Hot rolling |

|

Surface treatment |

Sandblasting,pickling, polished |

|

Shipping Terms |

Express,Air,Shipping or as your choice. |

|

Payment term |

TT prepayment or Negotiable |

|

Sample |

We can cut according to your requirements |

Mechanical properties

|

Performance indicator |

numerical range |

|

Tensile strength (σ b) |

≥ 895 MPa |

|

Elongation rate (δ 5) |

≥ 10% |

|

Yield strength (σ 0.2) |

≥ 870 MPa |

Available Grades and Materials

Grade 5 Ti-6Al-4V Standard

The most versatile option for general industrial applications.

Grade 5 ELI (Extra Low Interstitial)

Enhanced ductility for medical and critical aerospace applications.

Grade 23 Ti-6Al-4V ELI

Medical grade with superior biocompatibility for implant applications.

Manufacturing Process

Our manufacturing process ensures consistent quality through:

Vacuum Arc Remelting (VAR)

Creates homogeneous microstructure and removes impurities.

Hot Rolling

Achieves optimal grain structure and mechanical properties.

Solution Treatment and Aging

Develops the desired alpha-beta microstructure for peak performance.

Precision Machining

Delivers exact dimensions to your specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace Industry

- Aircraft structural components

- Jet engine parts

- Landing gear systems

- Fasteners and fittings

Medical Sector

- Orthopedic implants

- Dental implants

- Surgical instruments

- Prosthetic devices

Industrial Applications

- Chemical processing equipment

- Marine components

- Automotive parts

- Sporting goods

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Thickness Range: 1-50mm

Width: Up to 2000mm

Length: Up to 6000mm

Tolerance: ±0.1mm for thickness, ±2mm for width/length

Surface Finish: Hot rolled, cold rolled, or machined

Product Features in Detail

Our titanium 6al-4v plate exhibits remarkable versatility across multiple industries. The balanced composition creates an ideal combination of strength and workability. You can easily machine, weld, and form these plates using standard metalworking techniques.

The alpha-beta microstructure provides excellent mechanical properties at both room and elevated temperatures. This makes our plates suitable for demanding applications where other materials would fail.

Quality Assurance and Testing

Standards Compliance

- ASTM B265 Grade 5

- EN 10204 3.1

Testing Procedures

- Chemical composition analysis

- Mechanical property testing

- Ultrasonic inspection

- Surface quality examination

Certifications

Each shipment includes material certificates and test reports documenting compliance with your specifications.

|

|

|

OEM & Customization Services

We understand that your projects have unique requirements. Our team provides:

- Custom cutting and machining

- Specific dimensional tolerances

- Surface treatments

- Heat treatment services

- Small to large quantity orders

Packaging and Shipping

Protective Packaging

Your plates are carefully wrapped in protective film and wooden crates to prevent damage during transit.

Global Shipping

We ship worldwide with reliable logistics partners, ensuring on-time delivery to over 50 countries.

Documentation

Complete shipping documentation and material certificates accompany every order.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in Baoji, China's "Titanium Capital," we offer unmatched expertise in titanium processing. Our founder's 30+ years of experience ensures you receive materials that meet the highest quality standards.

We focus on customer satisfaction through competitive pricing, reliable delivery, and comprehensive technical support. When you choose our titanium 6al-4v plate, you partner with a trusted supplier committed to your success.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate orders from small prototypes to large production runs.

Q: Can you provide custom dimensions?

A: Yes, we offer precision cutting and machining to your exact specifications.

Q: What certifications do you provide?

A: All materials include complete mill test certificates and compliance documentation.

Q: How long is the delivery time?

A: Standard delivery is 2-4 weeks, depending on specifications and quantity.

Contact Us

Ready to discuss your titanium 6al-4v plate requirements? Our technical team is ready to help you select the right material for your application.

Email us at info@chdymetal.com for quotes, technical specifications, or any questions about our titanium alloy products. We respond promptly to all inquiries and look forward to supporting your next project.

Learn about our latest products and discounts through SMS or email