- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Product Introduction

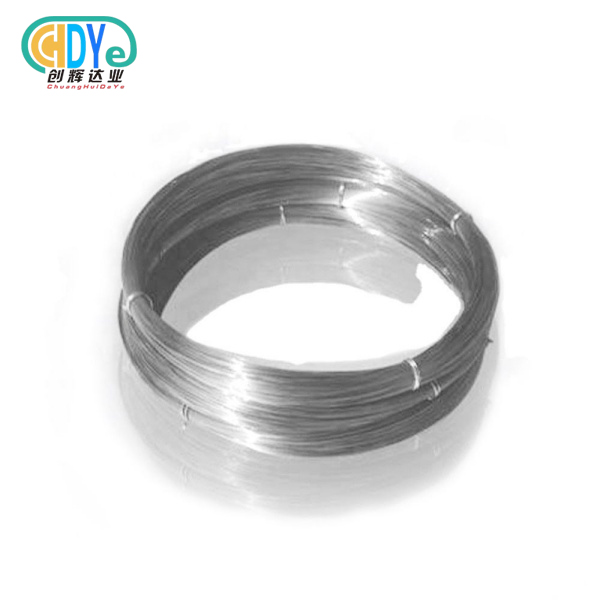

The Pure Molybdenum Wire supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a premium-grade refractory metal product designed for superior performance in demanding industrial environments. Manufactured from ultra-high-purity molybdenum, this wire features exceptional thermal conductivity, high melting point, excellent mechanical strength, and remarkable resistance to oxidation and corrosion. Each wire is precisely fabricated under strict quality control to meet international standards such as ASTM B387 and GB/T 4182, ensuring stability and reliability in various high-temperature and high-vacuum applications.

With over 30 years of experience in the rare metal industry, our company integrates advanced production technology with refined process management. The result is a wire that performs consistently in critical operations, such as electronic component production, heating elements, and wire cutting systems. Whether for laboratory use, semiconductor processing, or industrial furnaces, Pure Molybdenum Wire provides consistent performance and long service life, making it an ideal choice for global manufacturers seeking both precision and durability.

Pure Molybdenum wire is a filament material made of high-purity molybdenum with excellent high-temperature performance, corrosion resistance, and mechanical properties.

|

Products Name |

Molybdenum (Mo) Wire |

|

Material |

Mo, MoLa, etc. |

|

Standard |

ASTM F 289,ASTM B 289 |

|

Size |

φ0.08~φ3mm×L |

|

Purity |

99.95% |

|

Density |

10.2g/cm³ |

|

Surface |

Black Wire, Bright Wire |

|

Technology Process |

Forged, Drawn, Polished |

|

Certification |

ISO9001:2015 |

|

Delivery time |

10-15days according to your quantity |

Characteristics

high melting point, low thermal expansion coefficient, high strength, good electrical and thermal conductivity, and corrosion resistance. The melting point of molybdenum wire is as high as 2620℃, and it can remain stable at high temperatures and will not melt or deform easily. Its thermal expansion coefficient is extremely low, only one-third of that of steel, so it can maintain the stability of shape and length in high temperature environments. Pure Molybdenum wire has high strength and can remain stable even in high temperature and high pressure environments. In addition, molybdenum wire has good electrical and thermal conductivity, which makes it widely used in the electronics and electrical industries.

Application Advantages

Used for winding core wires, supports, lead wires, heating elements, molybdenum foil strips, wire cutting, auto parts spraying, etc.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is located in Baoji High-tech Development Zone, Shaanxi Province, known as China's "Titanium Capital", with convenient transportation. The founder of the company has more than 30 years experience in the rare metal industry, with rich experience and strong professional ability. He serves the majority of users wholeheartedly and strives to provide users with satisfactory products.

Our main products are: titanium, tantalum, niobium, tungsten, molybdenum, nickel and other non-ferrous and rare metal alloy products, products are widely used in metallurgy, electronics, medical and special steel fields. The company focus on quality assurance, customer first. Our company products successfully applied in the United States, Germany, South Korea, Singapore and other more than 50 countries and regions of the world.

We provide to our customers a competitive cost, on-time delivery, customer focused service, trust, reliability, honesty and continuous improvement. Please do not hesitate to contact us if you plan to work with a strong, reliable and a competitive partner.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye employs advanced manufacturing technology to ensure consistent quality and precision in every Pure Molybdenum Wire produced. The typical process flow includes:

- Raw Material Selection – Use of high-purity molybdenum powder with controlled impurity levels.

- Pressing and Sintering – The powder is pressed into bars and sintered in a high-temperature hydrogen atmosphere to achieve high density.

- Hot and Cold Rolling – The sintered bars are rolled and drawn under strict control to obtain uniform microstructure.

- Wire Drawing and Annealing – Precision drawing equipment ensures consistent diameter and tensile strength, followed by annealing to improve ductility.

- Surface Treatment and Inspection – Final cleaning, straightening, and visual inspection guarantee smooth surfaces and precise tolerances.

This meticulous process ensures that every product meets the highest mechanical and physical performance requirements.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is the foundation of our production philosophy. Each batch of Pure Molybdenum Wire undergoes rigorous inspection at every stage, including:

- Chemical Composition Analysis using spectrometric methods to confirm purity above 99.95%.

- Mechanical Testing for tensile strength, elongation, and hardness.

- Dimensional and Surface Inspection to ensure uniform diameter and defect-free finish.

- Ultrasonic and Visual Examination for detecting internal flaws and surface irregularities.

All products are manufactured under the ISO 9001:2015 Quality Management System, ensuring full traceability and consistency.

R&D and Customization

Our R&D team continuously explores innovative processing technologies and advanced applications of molybdenum materials. We can customize Pure Molybdenum Wire in various diameters, tolerances, and surface finishes according to customer requirements. Research efforts focus on improving wire flexibility, oxidation resistance, and high-temperature stability, enabling our products to meet specialized needs in semiconductors, medical devices, and aerospace components.

We also collaborate with research institutions to develop new molybdenum-based materials, ensuring technological leadership and product innovation.

Packaging & Global Logistics

Each wire is carefully packaged to preserve surface quality and prevent contamination during storage and transit. Standard packaging includes:

- Vacuum-sealed or Anti-rust Film wrapping for moisture and oxidation protection.

- Foam and Wooden Box Protection for shock resistance and structural safety.

- Clear Labeling of size, grade, batch number, and production date for full traceability.

Our logistics system supports air, sea, and land transportation to over 50 global markets, ensuring timely and safe delivery. Packaging strictly complies with international export standards to maintain integrity during shipping.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers flexible OEM and ODM services to meet diverse industrial requirements. We provide:

- Custom wire sizes, diameters, and mechanical properties.

- Special surface treatment or cleaning options.

- Prototype and small-batch production for R&D or pilot projects.

- Technical consultation and application support for end-users.

Our team ensures seamless cooperation and professional service from inquiry to final delivery, helping customers achieve optimal performance and cost efficiency.

Inspection Process

Every production batch follows a comprehensive inspection procedure before dispatch:

- Raw Material Testing – Chemical and physical analysis before production.

- In-process Monitoring – Real-time control of drawing, rolling, and annealing.

- Final Inspection – Dimensional verification, mechanical testing, and visual review.

- Certification – Issuance of test reports and conformity certificates upon customer request.

This ensures that only products meeting the highest standards leave our factory.

Why Choose Us

- 30+ Years of Industry Expertise – Deep technical experience in rare and refractory metals.

- Advanced Production Equipment – Precision melting, rolling, and machining systems.

- Global Market Coverage – Products exported to over 50 countries worldwide.

- Comprehensive Quality Management – ISO 9001:2015 certified production process.

- Fast Delivery & Reliable Service – Standard and customized orders shipped within 7 days.

Shaanxi Chuanghui Daye is committed to providing reliable, high-performance molybdenum materials backed by professional service and technical support.

|

|

|

|

|

|

FAQs

Q1: What is the purity of your molybdenum wire?

A1: Our standard purity is ≥99.95%, ensuring excellent mechanical and thermal stability for critical applications.

Q2: What sizes are available?

A2: We offer wire diameters from 0.05 mm to 3.0 mm, with customization available according to specific requirements.

Q3: Can you provide test certificates?

A3: Yes, we provide full inspection reports and certificates of analysis for each shipment.

Q4: Do you support small-batch orders?

A4: Absolutely. We accept prototype and trial orders to support R&D and pilot production.

Q5: What is the delivery time?

A5: Standard sizes are available for shipment within 7 days, and customized orders depend on the specifications and quantity.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email