- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

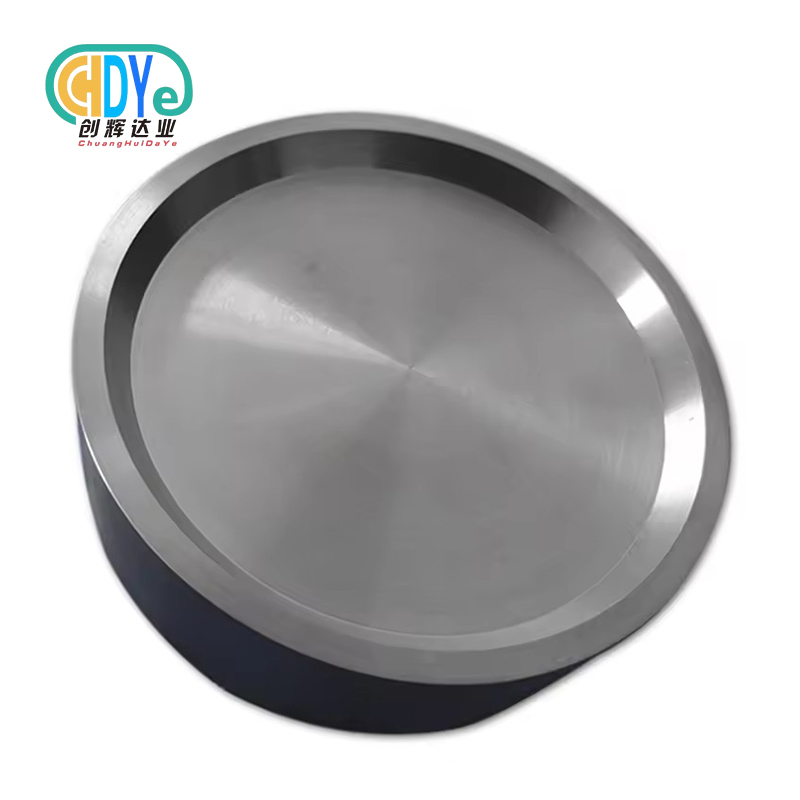

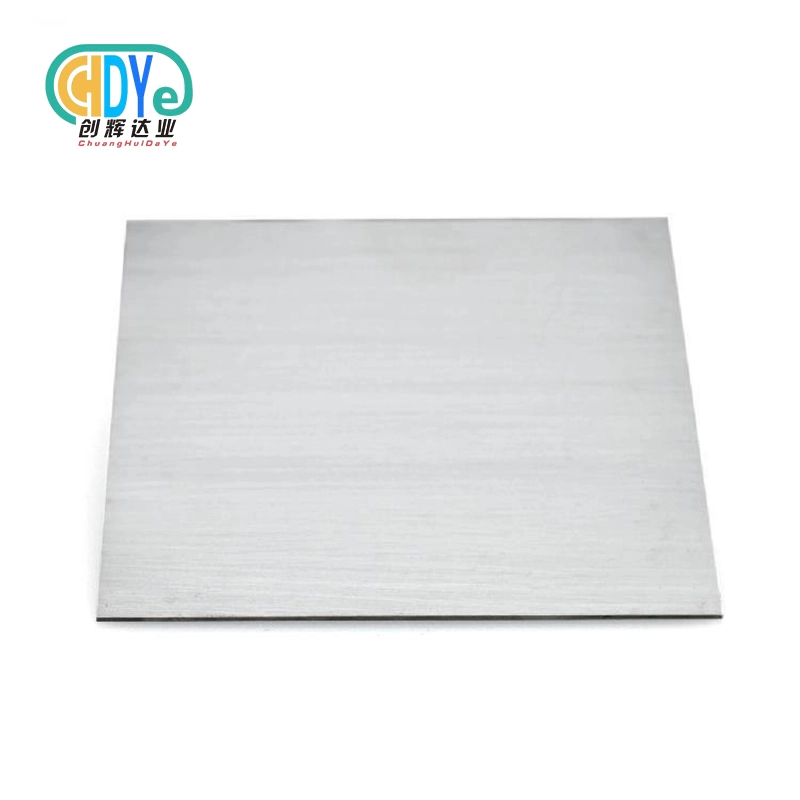

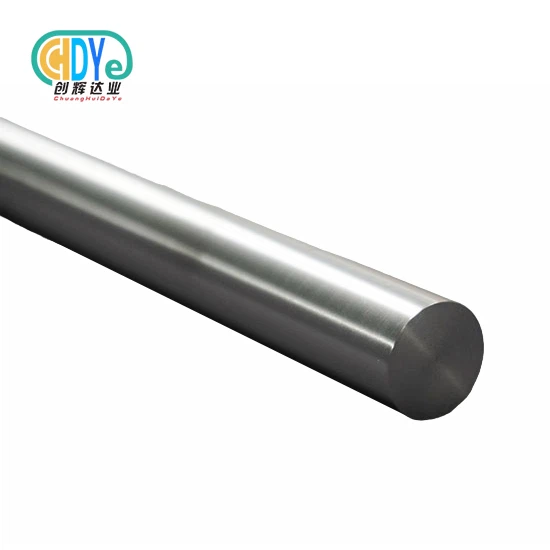

titanium alloy plate gr5

2. Thickness : 0.8-30mm

3. Density 4.43 g/cm³

4. Tensile strength 895-960 MPa

5. Aerospace applications

6. Excellent corrosion resistance

7. High fatigue resistance

Product Introduction

Looking for superior strength and reliability in your critical applications? Our titanium alloy plate gr5 delivers exceptional performance that meets the most demanding industrial requirements. Manufactured from Ti-6Al-4V alloy, this premium material combines 90% pure titanium with 6% aluminum and 4% vanadium to create an unmatched balance of strength, durability, and corrosion resistance. You'll find our Grade 5 titanium plates ideal for aerospace, marine, medical, and high-performance applications where quality cannot be compromised.

Key Features and Benefits

- Superior Strength-to-Weight Ratio: Lighter than steel yet stronger than most metals

- Outstanding Corrosion Resistance: Performs excellently in harsh chemical environments

- High Fatigue Resistance: Withstands repeated stress cycles without failure

- Excellent Weldability: Easy to join and fabricate for complex applications

- Biocompatibility: Safe for medical and food-grade applications

- Heat Treatability: Can be enhanced through precipitation hardening

Technical Specifications

| Property | Value |

|---|---|

| Alloy Composition | Ti-6Al-4V (90% Ti, 6% Al, 4% V) |

| Density | 4.43 g/cm³ |

| Tensile Strength | 895-960 MPa |

| Yield Strength | 825-895 MPa |

| Melting Point | 1,604-1,660°C |

| Diameter range | 0.8-30MM |

| Standard | ASTM B265 Grade 5 |

| Certificate | ISO 9001:2015 |

| Surface | bright surface |

| Condition | Annealed |

| Standard | ASTM B 265 |

| Delivery time | stock size 1-3 days, usually 0.8mm,1mm, 2mm 3mm, 4mm,5mm all have in stock |

Available Grade

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

mechanical properties

|

Performance indicator |

numerical range |

|

Tensile strength (σ b) |

≥ 895 MPa |

|

Elongation rate (δ 5) |

≥ 10% |

|

Yield strength (σ 0.2) |

≥ 870 MPa |

|

Sectional shrinkage rate (ψ) |

≥ 25% |

Available Grades and Materials

We specialize in titanium alloy plate gr5 manufactured to meet various international standards:

- ASTM B265 Grade 5: Standard specification for titanium plates

- EN 10204 3.1: European compliance certification

Manufacturing Process

Our advanced manufacturing process ensures consistent quality in every plate. We begin with premium titanium sponge and carefully controlled alloying elements. The material undergoes vacuum arc remelting for homogeneous composition. Hot rolling and precision machining create plates with excellent surface finish and dimensional accuracy. Each batch receives rigorous testing to guarantee mechanical properties and chemical composition.

|

|

|

|

|

|

|

|

Applications and Industries

Your projects benefit from Grade 5 titanium's versatility across multiple sectors:

Aerospace Industry

- Aircraft structural components

- Engine parts and turbine blades

- Landing gear components

Marine Applications

- Ship hull components

- Offshore platform structures

- Submarine parts

Medical Sector

- Surgical implants

- Dental applications

- Medical device components

Industrial Applications

- Chemical processing equipment

- Oil and gas industry components

- Automotive racing part

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We offer flexible sizing options to meet your specific requirements:

- Thickness: 0.8mm to 30mm

- Width: Up to 2000mm

- Length: Up to 6000mm

- Tolerance: ±0.1mm for thickness, ±1mm for width and length

- Surface Finish: Hot rolled, cold rolled, or machined

Product Features in Detail

Our titanium alloy plate gr5 stands out through superior manufacturing standards. The carefully controlled Ti-6Al-4V composition provides optimal mechanical properties for demanding applications. You'll appreciate the consistent grain structure that ensures uniform performance throughout the plate. The excellent surface quality reduces machining time and improves final product appearance.

Quality Assurance and Testing

Every plate undergoes comprehensive testing protocols:

- Chemical Composition Analysis: Spectroscopic verification

- Mechanical Property Testing: Tensile, yield, and elongation tests

- Ultrasonic Testing: Internal defect detection

- Surface Inspection: Visual and dimensional verification

- Mill Test Certificates: Complete documentation provided

|

|

|

OEM & Customization Services

We understand that your applications may require specific dimensions or properties. Our engineering team works closely with you to develop customized solutions. Whether you need special surface treatments, unique dimensions, or modified compositions, we provide tailored titanium alloy plate gr5 solutions that meet your exact specifications.

Packaging and Shipping

Your orders receive careful packaging to prevent damage during transit. We use wooden crates with protective padding for international shipments. Each package includes complete documentation and certificates. Our logistics team coordinates with reliable carriers to ensure timely delivery to your facility.

|

|

|

|

|

|

|

|

|

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of expertise in rare metal processing. Located in China's "Titanium Capital," we have direct access to premium raw materials and advanced manufacturing facilities. Our commitment to quality has earned trust from customers in over 50 countries worldwide. You receive competitive pricing, reliable delivery, and exceptional technical support with every order.

|

|

|

|

|

|

FAQs

Q: What makes Grade 5 titanium different from pure titanium?

A: Grade 5 titanium offers significantly higher strength and better wear resistance compared to pure titanium grades.

Q: Can you provide smaller quantities for prototyping?

A: Yes, we accommodate both large production orders and small prototype quantities.

Q: What certifications do you provide?

A: We provide mill test certificates, chemical composition reports, and mechanical property test results with every shipment.

Q: How do you ensure consistent quality?

A: Our quality management system includes incoming material inspection, process control, and final product testing.

Contact Us

Ready to experience the superior performance of our titanium alloy plate gr5? Our technical team is ready to assist with your material selection and specification requirements. Contact us today at info@chdymetal.com for detailed quotations, technical data sheets, and expert consultation on your titanium plate needs.

Learn about our latest products and discounts through SMS or email