- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

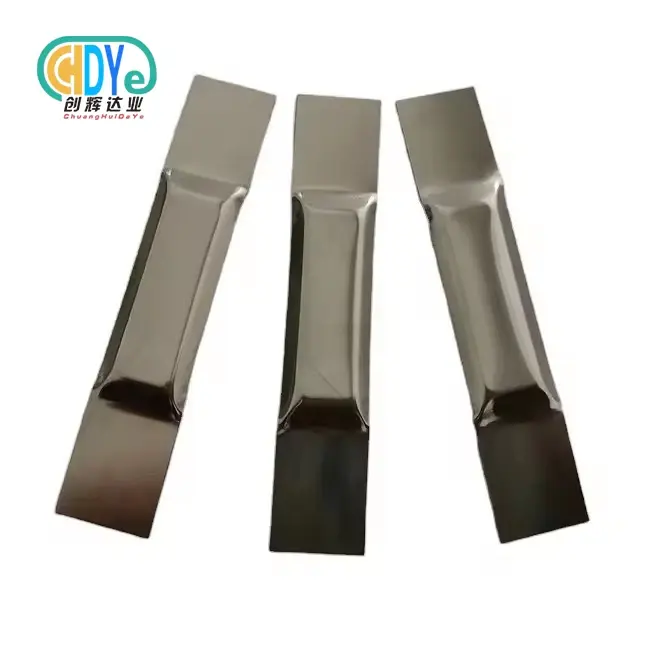

Tungsten Crucible

Product Introduction

The high-performance crucible from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is precision-engineered using ultra-high-purity tungsten, making it ideal for extreme operating conditions. It offers outstanding thermal conductivity, excellent chemical stability, and superior mechanical strength at elevated temperatures. Manufactured to meet strict international standards, this product is suitable for applications in metallurgy, electronics, semiconductors, vacuum systems, and laboratory research.

Thanks to tungsten’s exceptionally high melting point of around 3422°C, the crucible can endure prolonged exposure to intense heat without warping or chemical degradation. It is particularly well-suited for high-temperature metal melting, vacuum furnace operations, and semiconductor processing where thermal stability and contamination-free conditions are crucial.

Tungsten’s unique properties—such as high melting point, corrosion and wear resistance, and a low coefficient of thermal expansion—make it widely used in sapphire single crystal growth, quartz glass melting, rare-earth material processing, and electronic deposition applications.

Description

Grade : W1

Application : Used for sapphire crystal growing, rare earth metal metallurgy.

|

Commodity |

Material |

Specification |

Tolerance |

Density |

|

Tungsten Crucible |

Pure W |

Φ(50-800)mm*(5-850)mm |

±0.5mm |

≥9.9g/cm³ |

|

Diameter(mm) |

Thickness(mm) |

Height(mm) |

|

30-50 |

2-5 |

|

|

150-300 |

3-10 |

|

|

300-400 |

10-15 |

|

|

400-600 |

15-20 |

|

|

600-800 |

20-50 |

Product Features:

Excellent high temperature resistance: can be used in high temperature melting and other processes, such as in the melting of some rare metals (such as tantalum, niobium), can withstand the high temperature required for the melting of these metals, to ensure the smooth melting process. - Strong corrosion resistance: In some high temperature scenarios where the corrosive environment is relatively weak, tungsten crucible can maintain good stability, thereby extending the service life. - High thermal conductivity: Tungsten has a high thermal conductivity and can quickly and evenly conduct heat, which is conducive to uniform heating of the material in the crucible, which is very important in metal melting or high-temperature chemical reactions.

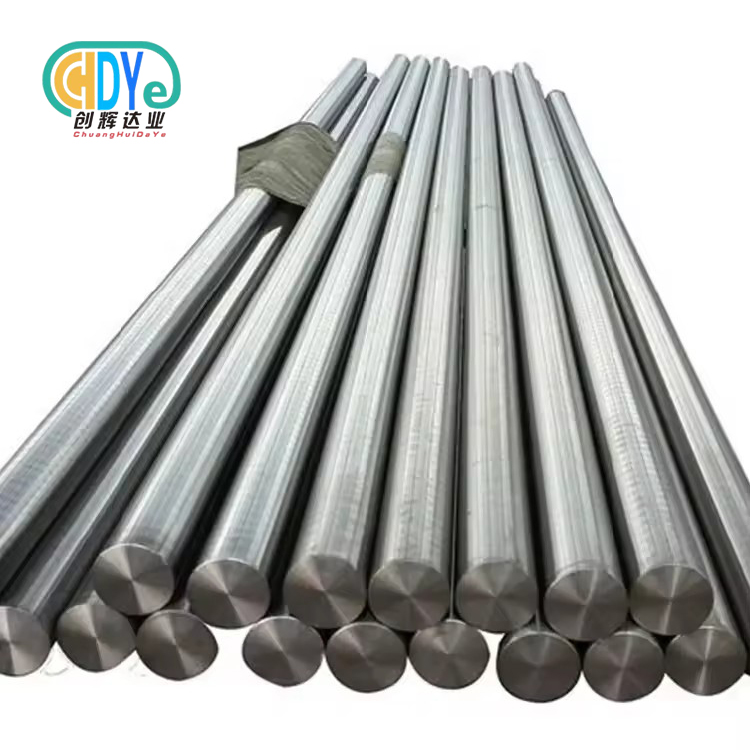

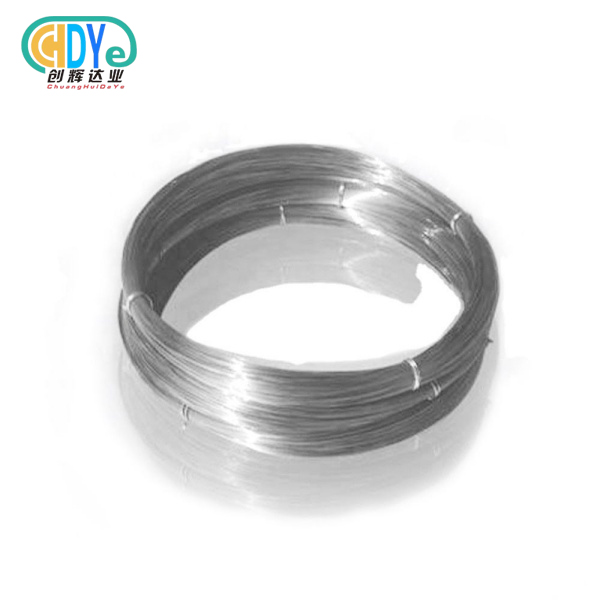

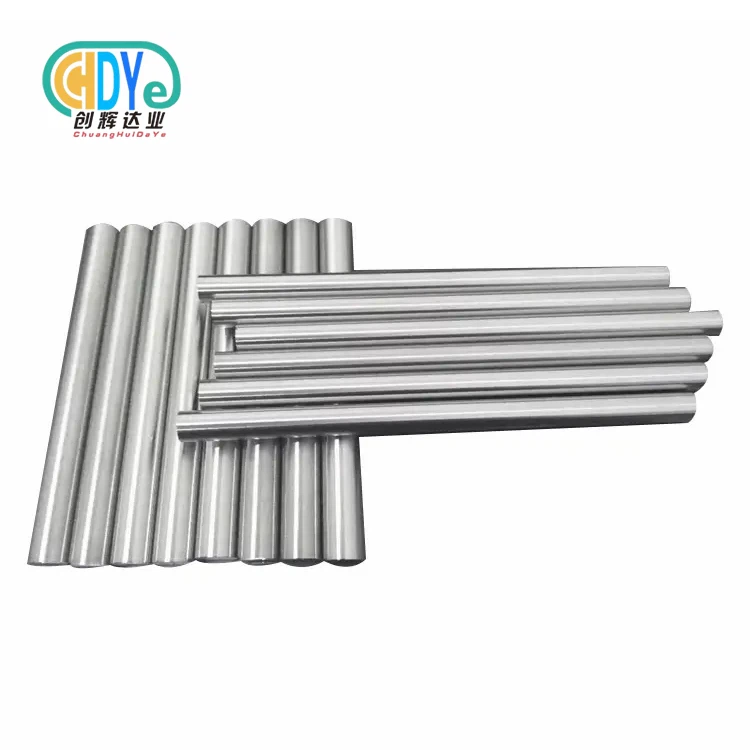

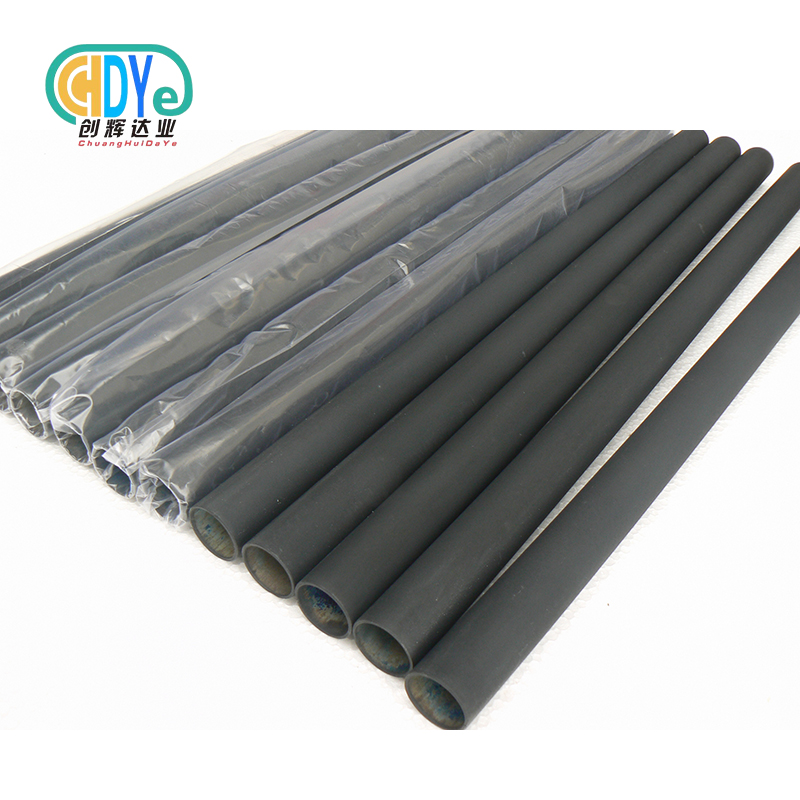

Our Products

Application Advantages

- Metal smelting: widely used in the smelting of rare earth metals and refractory metals. - High temperature chemical

-experiment: as a reaction vessel in the process of high temperature chemical synthesis, high -temperature sintering and other experiments, to ensure that the experiment can be stable under high temperature conditions.

Shipping

Various Mode of Transportation for you: we cooperate with reliable and economical forwarder.

Air transportation

Sea transportation

By Express: DHL, FedEX, UPS, EMS, etcour factory appearance

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of the Tungsten Crucible follows a meticulously controlled process to guarantee high quality and consistency. The main steps include:

- High-Purity Tungsten Powder Selection: Only premium-grade tungsten powder is selected to ensure chemical purity and consistent microstructure.

- Powder Compaction and Sintering: Tungsten powder is compacted under high pressure and sintered in vacuum or inert atmospheres to create dense, uniform structures.

- Hot Pressing & Forging: To enhance mechanical strength, sintered blanks undergo hot pressing and forging under controlled conditions.

- Precision Machining: Using advanced CNC machines and electron beam furnaces, the crucibles are precisely machined to meet tight dimensional tolerances.

- Surface Treatment: Final polishing and cleaning processes remove surface impurities, ensuring a smooth finish suitable for high-purity applications.

- Quality Checks Throughout: In-process inspections are carried out to monitor density, dimensions, and surface quality, guaranteeing that each crucible meets our strict standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is a cornerstone of Shaanxi Chuanghui Daye’s manufacturing philosophy. The Tungsten Crucible undergoes rigorous inspection procedures, including:

- Chemical Composition Verification: Ensuring that the tungsten content is above 99.95% and free of contaminants.

- Dimensional Accuracy Checks: Each crucible is measured using precision instruments to ensure adherence to design specifications.

- Density & Porosity Testing: High-density crucibles with minimal porosity are critical for thermal performance and structural integrity.

- High-Temperature Performance Evaluation: Crucibles are tested under extreme temperatures to verify thermal stability and resistance to deformation.

- Surface Integrity Assessment: Polished and finished surfaces are inspected to avoid micro-cracks or irregularities that could affect high-purity applications.

R&D and Customization

Shaanxi Chuanghui Daye invests heavily in research and development to provide innovative and tailored solutions for our clients. Our R&D team works closely with customers to develop Tungsten Crucible designs that meet specific requirements:

- Custom Sizes and Shapes: From small laboratory crucibles to large industrial-scale components, we can fabricate various dimensions and wall thicknesses.

- Specialized Tolerances: Precision machining allows tight tolerances for applications requiring exact fit and performance.

- Prototype and Small-Batch Production: Customers can request prototypes or small series for testing before full-scale production.

- Material Optimization: Depending on the application, our team can optimize the microstructure and purity of tungsten to maximize performance and longevity.

Packaging & Global Logistics

To protect the crucibles during international transport, we employ a meticulous packaging and logistics system:

- Packaging: Crucibles are wrapped with vacuum or anti-rust films, cushioned with foam, and secured in export-standard wooden crates.

- Marking: Each crucible is clearly labeled with product specifications, batch numbers, and handling instructions.

- Transportation: We provide air, sea, and land shipping options, ensuring timely delivery to over 50 countries, including the United States, Germany, Mexico, France, South Korea, and Singapore.

This comprehensive packaging and logistics approach guarantees that the Tungsten Crucible reaches clients in optimal condition, ready for immediate use.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye offers OEM and ODM services to accommodate diverse industrial requirements. Customers can specify:

- Crucible dimensions, wall thickness, and shapes

- Material purity and mechanical properties

- Prototype and small-batch production for validation

- Full technical consultation and post-sales support

Inspection Process

Inspection is performed at every stage of production to ensure the highest quality:

- Raw Material Verification – Ensuring the tungsten powder meets strict chemical purity standards.

- In-Process Monitoring – Density, temperature, and structural integrity are continuously checked during sintering and forging.

- Dimensional Checks – Precision measurements guarantee conformity to specifications.

- Final Performance Testing – Crucibles undergo high-temperature and surface integrity evaluations.

- Packaging Verification – Ensures that each product is protected and labeled correctly before shipment.

Why Choose Us

- Over 30 years of experience in rare metal materials

- ISO 9001:2015 certified quality management system

- Advanced equipment, including electron beam furnaces, lathes, rolling machines, and annealing furnaces

- Fast 7-day delivery for standard products

- Global export network and professional OEM support

- Commitment to continuous innovation and customer satisfaction

|

|

|

|

|

|

FAQs

Q1: What is the maximum temperature the crucible can withstand?

A1: The Tungsten Crucible can tolerate temperatures up to 3400°C in inert atmospheres, making it suitable for extreme high-temperature operations.

Q2: Are custom sizes available?

A2: Yes, we provide full customization, including diameter, height, and wall thickness, according to client specifications.

Q3: Which industries benefit most from this crucible?

A3: Metallurgy, semiconductors, vacuum technology, laboratory research, and aerospace industries.

Q4: How is quality ensured?

A4: Through chemical analysis, density and porosity testing, dimensional verification, high-temperature performance evaluation, and surface integrity inspection.

Q5: Can you ship globally?

A5: Yes, Shaanxi Chuanghui Daye provides reliable international shipping to over 50 countries, ensuring safe and timely delivery.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email