- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

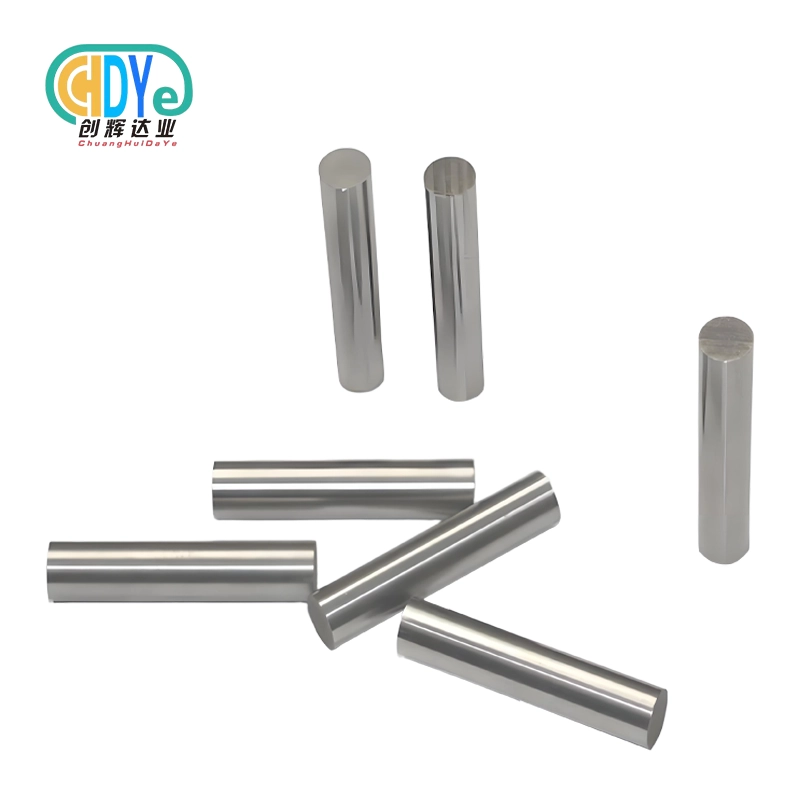

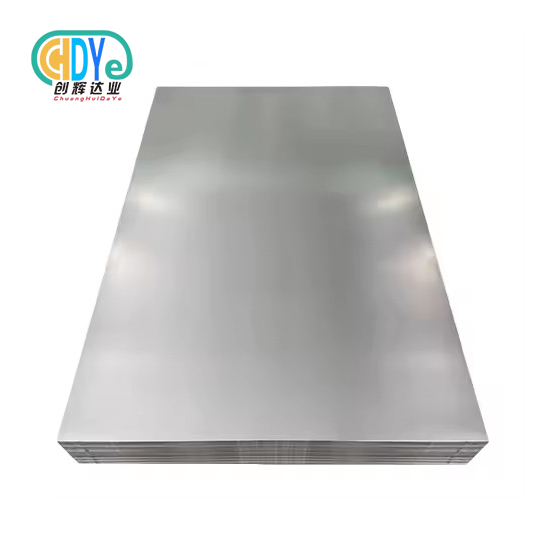

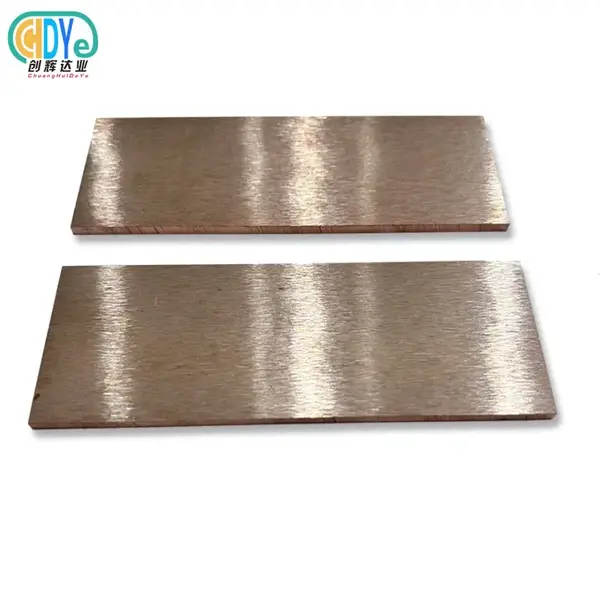

Tungsten Copper Plate

2.Surface: polished

3.Standard: ASTM B760-07

Product Introduction

The Tungsten Copper Plate produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is an advanced composite material that combines the high thermal conductivity and electrical performance of copper with the excellent wear resistance and high-temperature strength of tungsten. This unique alloy structure ensures remarkable durability, stable conductivity, and superior resistance to arc erosion and deformation. Manufactured under strict quality standards such as ASTM and GB, the product is widely used in demanding industries including aerospace, electrical power, metallurgy, and electronic devices. Each plate is processed with high precision to deliver consistent performance, dimensional accuracy, and long service life under extreme operating conditions.

Tungsten copper plates and sheets are highly sought-after flat materials for demanding applications such as high voltage, high temperature, resistance welding, and EDM (Electrical Discharge Machining). These materials offer excellent resistance to thermal and electrical erosion, alongside superior conductivity, low thermal expansion, and excellent machinability. The combination of tungsten and copper brings together the best of both metals, making them ideal for use in environments where both strength and electrical efficiency are required.

Grade: CuW90 CuW85 CuW80 CuW75 CuW70

Surface: polished

Standard: ASTM B760-07

|

Grade |

Chemical composition(%) |

Physical and Mechanical properties |

||||||

|

Cu |

Impurity |

W |

Density g/cm3 |

HB |

μΩ.cm |

IACS/% |

TRS/MPa |

|

|

W50Cu50 |

50±2.0 |

0.5 |

rest |

11.85 |

115 |

3.2 |

54 |

|

|

W55Cu45 |

45±2.0 |

0.5 |

rest |

12.3 |

125 |

3.5 |

49 |

|

|

W60Cu40 |

40±2.0 |

0.5 |

rest |

12.75 |

140 |

3.7 |

47 |

|

|

W65Cu35 |

35±2.0 |

0.5 |

rest |

13.3 |

155 |

3.9 |

44 |

|

|

W70Cu30 |

30±2.0 |

0.5 |

rest |

13.8 |

175 |

4.1 |

42 |

790 |

|

W75Cu25 |

25±2.0 |

0.5 |

rest |

14.5 |

195 |

4.5 |

38 |

885 |

|

W80Cu20 |

20±2.0 |

0.5 |

rest |

15.15 |

220 |

5.0 |

34 |

980 |

|

W85Cu15 |

15±2.0 |

0.5 |

rest |

15.9 |

240 |

5.7 |

30 |

1080 |

|

W90Cu10 |

10±2.0 |

0.5 |

rest |

16.75 |

260 |

6.5 |

27 |

1160 |

The characteristics:

1. High temperature resistance: Tungsten copper plate has extremely high temperature resistance and can withstand working conditions in high-temperature environments. The melting point of tungsten is 3410 ℃, while the melting point of copper is 1080 ℃, which allows tungsten copper alloys to maintain stable performance at high temperatures.

2. High strength and arc erosion resistance: Tungsten copper alloy has high strength and good arc erosion resistance, suitable for working environments that require high strength and arc erosion resistance. This characteristic makes tungsten copper sheets widely used in fields such as high-voltage switches and electrode machining.

3. Good electrical and thermal conductivity: Although tungsten has poor electrical conductivity, copper has superior electrical conductivity. Through a reasonable composition ratio, tungsten copper alloy can provide moderate electrical and thermal conductivity while maintaining high strength. This characteristic makes tungsten copper sheet perform well in applications such as electronic packaging and high-voltage discharge tubes.

4. High density and uniform microstructure: The microstructure of tungsten copper alloy is uniform and dense, which helps to improve the stability and service life of the material. The density of tungsten is 19.25g/cm ³, the density of copper is 8.92g/cm ³, and the density of alloys is generally around 16.5g/cm ³.

5. Wide application fields: tungsten copper sheet is widely used in aerospace, electronics, power, metallurgy, machinery and other fields due to its excellent performance. Specific applications include resistance welding electrodes, spark electrodes, high-voltage discharge tube electrodes, electronic packaging materials, etc.

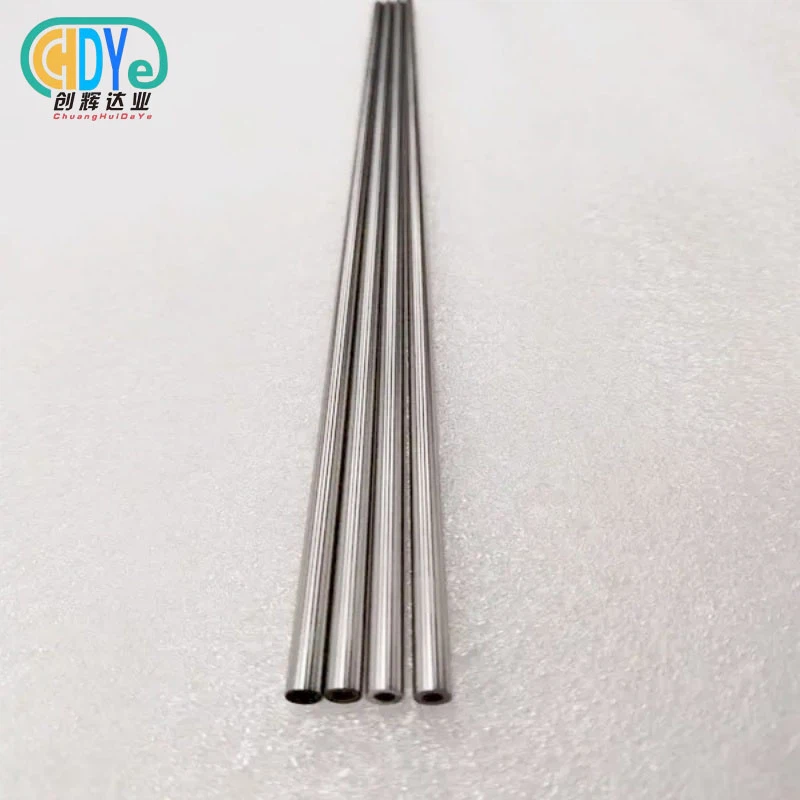

Our Products

Application Advantages

The application fields of tungsten copper sheets are very wide, mainly including the following aspects:

1.Aerospace and electronics fields

2. High voltage switches and electrical contact materials

3. Welding electrode

4. Electronic packaging and high-voltage electrical switches

5. Resistance welding and electrical discharge machining

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye employs advanced powder metallurgy and precision machining technologies to produce each Tungsten Copper Plate with superior consistency.

Main Production Steps:

- Raw Material Selection: Only ultra-fine tungsten and high-purity copper powders are used.

- Powder Mixing & Pressing: Homogeneous distribution of copper within the tungsten matrix ensures even density and conductivity.

- Sintering: Conducted in a controlled hydrogen atmosphere at high temperature to achieve strong bonding and low porosity.

- Infiltration: Molten copper is infiltrated into the tungsten skeleton for optimal conductivity and density.

- Machining & Finishing: Precision milling, grinding, and polishing ensure exact tolerances and excellent surface finish.

- Final Inspection: Each plate undergoes density, conductivity, and dimensional verification before packing.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is central to our production philosophy. The company follows ISO 9001:2015 standards to ensure that every Tungsten Copper Plate meets strict international specifications.

Inspection Procedures Include:

- Raw material composition analysis

- Density and porosity measurement

- Electrical conductivity testing

- Mechanical strength and hardness inspection

- Dimensional accuracy verification

- Surface flatness and finish evaluation

Each inspection step guarantees product reliability, traceability, and stable performance across all batches.

R&D and Customization

Our research and development team continually improves material properties and processing technology to meet diverse customer needs. Custom grades and dimensions of Tungsten Copper Plate can be tailored according to specific thermal, mechanical, or electrical requirements. Through cooperation with domestic and international research institutions, we develop high-purity, fine-grain, and ultra-high-conductivity versions for specialized use in semiconductor and aerospace sectors. Customers are supported with design optimization, prototype manufacturing, and small-batch testing to ensure best-fit solutions for their applications.

Packaging & Global Logistics

Each Tungsten Copper Plate is securely packaged using moisture-proof, anti-rust, and shock-resistant materials. Vacuum sealing or foam protection is applied to prevent surface damage during shipment. Products are packed in strong wooden cases compliant with international export standards.

Logistics Options:

- Air freight for urgent or small-batch deliveries

- Sea freight for large-volume international orders

- Land transport with full tracking for regional customers

Our global logistics network ensures safe, timely delivery to more than 50 countries, including the United States, Germany, South Korea, and France.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye offers comprehensive OEM and ODM services. Customers can specify composition ratios, dimensions, and surface treatments to achieve desired conductivity or wear resistance. Engineering teams provide full technical support from initial consultation to post-delivery service. Custom markings, batch tracking, and packaging labeling are available upon request. Whether for high-current electrical devices or heat-dissipation components, we provide tailored tungsten-copper material solutions for global clients.

Inspection Process

To ensure consistent quality, every production stage undergoes systematic inspection:

- Raw Material Verification: Ensuring purity and particle size control.

- Intermediate Testing: Density, conductivity, and bonding strength during sintering and infiltration.

- Final Dimensional Check: Precision inspection using coordinate measuring equipment (CMM).

- Surface Quality Control: Visual and microscopic examination for uniformity.

- Performance Testing: Conductivity, hardness, and temperature resistance analysis before final approval.

Only plates passing all test parameters proceed to final packaging and shipment.

Why Choose Us

- 30+ Years Industry Experience: Deep expertise in rare and refractory metals.

- Complete Quality System: ISO 9001:2015 certification ensures every product meets top standards.

- Advanced Manufacturing Facilities: Electron beam furnaces, precision rolling, and CNC machining.

- Global Market Presence: Trusted by customers in 50+ countries.

- Custom Engineering Solutions: OEM and ODM support for specialized industries.

- Fast Delivery & Reliable Service: Standard products delivered within 7 days.

|

|

|

|

|

|

FAQs

Q1: What is the composition range of tungsten and copper?

A1: Standard compositions include 70W–30Cu, 80W–20Cu, and 90W–10Cu, but custom ratios are available upon request.

Q2: What sizes are available for Tungsten Copper Plate?

A2: We provide thicknesses from 0.5 mm to 50 mm and custom-cut dimensions according to client drawings.

Q3: How is product quality guaranteed?

A3: Each production batch undergoes strict inspection, including chemical analysis, density, and conductivity tests.

Q4: Can small-batch or prototype orders be produced?

A4: Yes, our R&D center supports prototype and pilot production for testing and research purposes.

Q5: What is the typical delivery time?

A5: Standard sizes are available for shipment within 7 working days; customized orders depend on quantity and specifications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email