- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

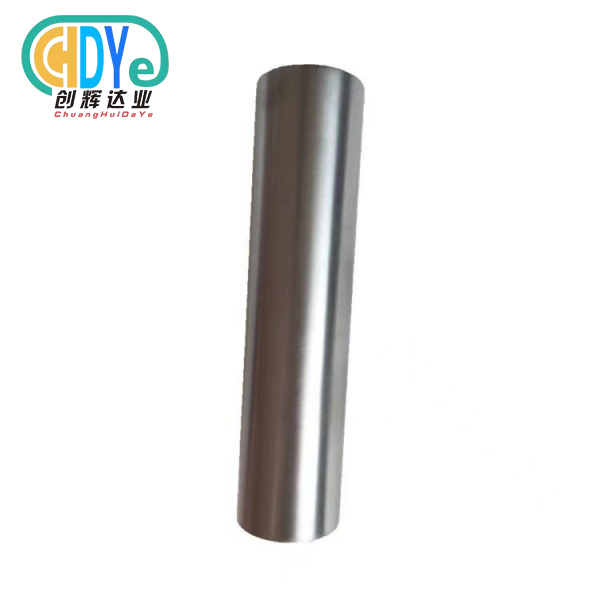

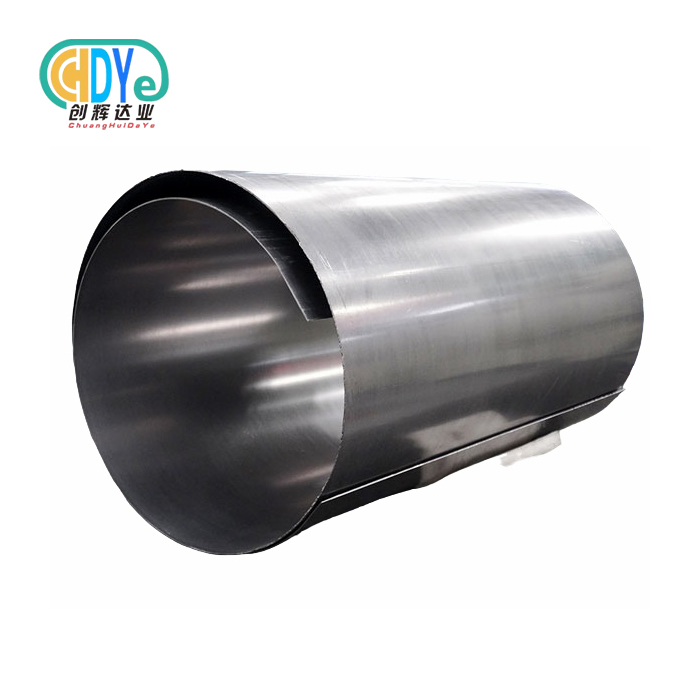

titanium plate grade 5

2. Thickness 1-50mm

3. Density 4.43 g/cm³

4. Tensile strength 895-960 MPa

5.Standard: ASTM B 265

6.Condition: annealed

Looking for superior strength and exceptional corrosion resistance? Our titanium plate grade 5 delivers outstanding performance for your most demanding applications. Made from premium Ti-6Al-4V alloy composition (6% aluminum, 4% vanadium, 90% pure titanium), these plates offer the perfect balance of strength, durability, and lightweight properties. Whether you need materials for aerospace, marine, or industrial applications, our grade 5 titanium plates provide reliable solutions that meet your specific requirements.

Key Features and Benefits

Our Ti-6Al-4V plates stand out in the industry for several compelling reasons. You get exceptional strength-to-weight ratio that significantly reduces overall component weight without compromising performance. The outstanding corrosion resistance ensures long-lasting durability even in harsh environments like saltwater and chemical processing.

These plates offer excellent fatigue resistance, making them ideal for cyclic loading applications. You'll appreciate the low thermal expansion properties that maintain dimensional stability across temperature variations. The high-temperature performance up to 430°C (806°F) expands your application possibilities.

Technical Specifications

|

Grade |

Gr5 (TI-6-Al-4V) |

|

Specification |

Thickness :0.5mm~50mm*Width:1000-3000mm |

|

Process method |

Cold rolling/Hot rolling |

|

Surface treatment |

Sandblasting,pickling, polished |

|

Shipping Terms |

Express,Air,Shipping or as your choice. |

|

Payment term |

TT prepayment or Negotiable |

|

Sample |

We can cut according to your requirements |

Gr5 titanium alloy sheets mechanical properties

|

Performance indicator |

numerical range |

|

Tensile strength (σ b) |

≥ 895 MPa |

|

Elongation rate (δ 5) |

≥ 10% |

|

Yield strength (σ 0.2) |

≥ 870 MPa |

|

Sectional shrinkage rate (ψ) |

≥ 25% |

Available Grades and Materials

We specialize in Ti-6Al-4V (Grade 5) titanium plates, the most widely used titanium alloy globally. This alpha-beta alloy provides optimal mechanical properties for demanding applications. Our plates conform to ASTM B265 standards.

You can choose from various surface finishes including mill finish, pickled, and polished options. We maintain extensive inventory to ensure quick delivery of standard sizes while offering custom dimensions for specialized requirements.

Manufacturing Process

Our manufacturing process begins with premium titanium sponge and alloying elements. We use vacuum arc remelting (VAR) technology to ensure uniform composition and eliminate impurities. The ingots undergo hot rolling and controlled cooling to achieve desired mechanical properties.

Quality control happens at every stage. We perform chemical analysis, mechanical testing, and dimensional inspection to guarantee consistency. Heat treatment processes optimize the microstructure for enhanced performance characteristics.

Applications and Industries

Aerospace Industry: Aircraft structural components, engine parts, landing gear, and fasteners benefit from the lightweight yet strong properties of titanium plate grade 5.

Marine Applications: Offshore platforms, submarine hulls, and propeller shafts rely on excellent saltwater corrosion resistance.

Medical Devices: Surgical implants, dental fixtures, and prosthetics utilize biocompatibility and strength.

Oil & Gas: Drilling equipment, heat exchangers, and pressure vessels operate reliably in corrosive environments.

Automotive: Racing components, exhaust systems, and suspension parts achieve weight reduction goals.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We offer comprehensive size ranges to meet your specifications:

- Thickness: 1mm to 50mm

- Width: Up to 2000mm

- Length: Up to 6000mm

- Tolerance: ±0.1mm for thickness, ±2mm for width/length

Custom cutting services include waterjet, plasma, and laser cutting for precise dimensions. We maintain tight tolerances to reduce your machining requirements and material waste.

Product Features in Detail

The Ti-6Al-4V composition creates unique properties you won't find in other materials. The aluminum content provides solid solution strengthening while maintaining ductility. Vanadium addition enhances strength and improves high-temperature performance.

Weldability makes fabrication straightforward using appropriate techniques. The material responds well to various machining operations when proper parameters are used. Surface treatments like anodizing and coating provide additional protection options.

Quality Assurance and Testing

Every batch undergoes rigorous testing protocols. Chemical composition verification ensures alloy specifications are met. Mechanical property testing confirms tensile strength, yield strength, and elongation values.

Non-destructive testing including ultrasonic inspection detects internal defects. Surface quality inspection ensures smooth, defect-free finishes. Mill test certificates accompany every shipment for traceability.

OEM & Customization Services

We understand that standard sizes don't always meet your needs. Our customization services include precision cutting, surface finishing, and special packaging. Whether you need prototype quantities or production volumes, we adapt to your requirements.

Our engineering team collaborates with you to optimize material selection and dimensions. We provide technical support throughout your project development process.

Packaging and Shipping

Protective packaging prevents damage during transit. We use wooden crates, foam padding, and moisture barriers for international shipments. Proper labeling and documentation ensure smooth customs clearance.

Multiple shipping options accommodate urgent and standard delivery requirements. Our logistics team coordinates with reliable carriers to ensure on-time delivery worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, we understand your challenges. Located in China's "Titanium Capital," we have direct access to premium raw materials and advanced manufacturing facilities.

Our commitment to quality, competitive pricing, and customer service sets us apart. We've successfully served customers in over 50 countries, building lasting partnerships through reliability and trust.

|

|

|

|

|

|

Feed back from Customers

|

|

|

FAQs

Q: What's the difference between Grade 5 and pure titanium?

A: Titanium plate grade 5 offers significantly higher strength and temperature resistance compared to pure titanium grades.

Q: Can you provide custom sizes?

A: Yes, we offer custom cutting and sizing services to meet your specific requirements.

Q: What certifications do you provide?

A: We provide mill test certificates and can arrange third-party testing when required.

Q: What's the typical lead time?

A: Standard sizes ship within 5-7days, while custom orders typically require 2-3 weeks.

Contact Us

Ready to discuss your titanium plate grade 5 requirements? Our technical team is here to help you select the right specifications for your application.

Email: info@chdymetal.com

Contact us today for competitive pricing, technical specifications, and delivery schedules. We're committed to providing you with premium quality titanium plates that exceed your expectations.

Learn about our latest products and discounts through SMS or email