- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

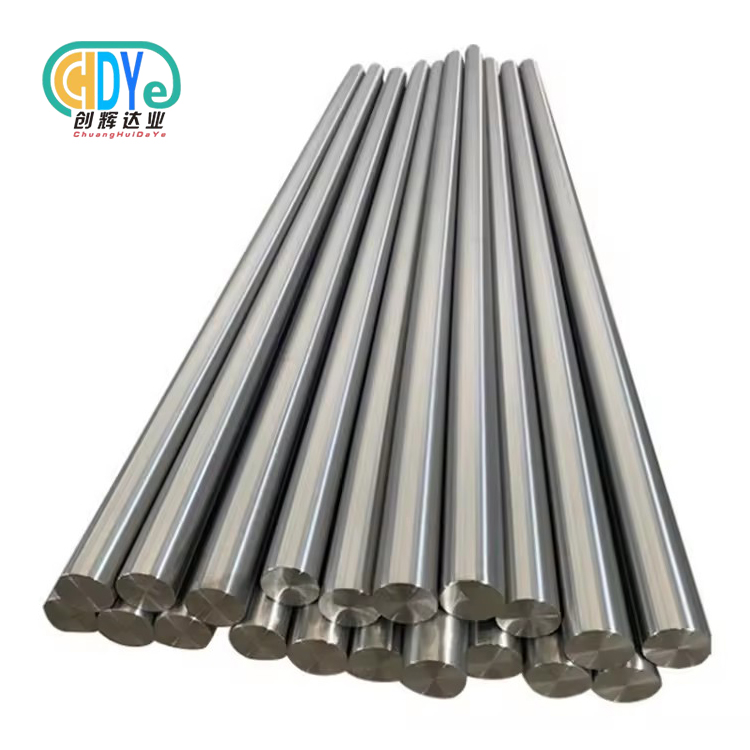

niobium alloy tube

2. Standard: ASTM B 394

3. State: Hard, semi-hard and soft

4.Size: customized

Product Introduction

Welcome to Shaanxi Chuanghui Daye Metal Material Co., Ltd., your trusted partner for premium niobium alloy tube solutions. Our expertly manufactured tubes combine exceptional strength, corrosion resistance, and high-temperature performance. Each tube meets stringent quality standards and offers outstanding durability for demanding applications. Whether you need specialized aerospace components or chemical processing equipment, our tubes deliver reliable performance. With over 30 years of industry experience, we provide superior products that exceed expectations and support your critical operations worldwide.

Key Features and Benefits

Our tubes offer remarkable advantages for your applications:

- Superior corrosion resistance - Perfect for harsh chemical environments

- Excellent high-temperature stability - Maintains strength up to extreme temperatures

- Outstanding ductility - Easy fabrication and forming capabilities

- Low neutron capture cross-section - Ideal for nuclear applications

- Biocompatibility - Safe for medical and prosthetic uses

- Lightweight yet strong - Reduces overall system weight while maintaining performance

Technical Specification

|

Size |

OD3-100*wall thickness 0.5-5mm*Length200-6000mm |

|

Material |

Pure niobium and niobium alloy |

|

Grade |

R04200, R04210, R04251,R04261 |

|

Standard |

ASTM B394 |

|

Purity |

> 99.95% or 99.9% |

|

Density |

8.57g/cm3 |

|

Type |

Seamless and welded |

|

Characteristic |

Melting point : 2468℃ / Boiling point : 4744℃ |

|

Product Features |

Excellent Corrosion Resistance , Good resistance to effect of heat |

|

Packing |

Plastic foam inside, wooden box outside |

|

Delivery time |

Stock size within 1-5 days, normal production time about 15 days |

|

Payment terms |

30%TT in advance,70% balance before shipment |

Available Grades and Materials

We offer premium alloy combinations:

- Nb-Ti alloys - Enhanced superconducting properties

- Nb-Zr alloys - Superior strength and corrosion resistance

- Pure niobium - Maximum ductility and biocompatibility

Manufacturing Process

Our advanced production ensures consistent quality. We start with high-purity raw materials and employ precision forming techniques. Each niobium alloy tube undergoes careful heat treatment and dimensional control. Our skilled technicians monitor every step to guarantee optimal properties and perfect finishes.

|

|

|

|

|

|

|

|

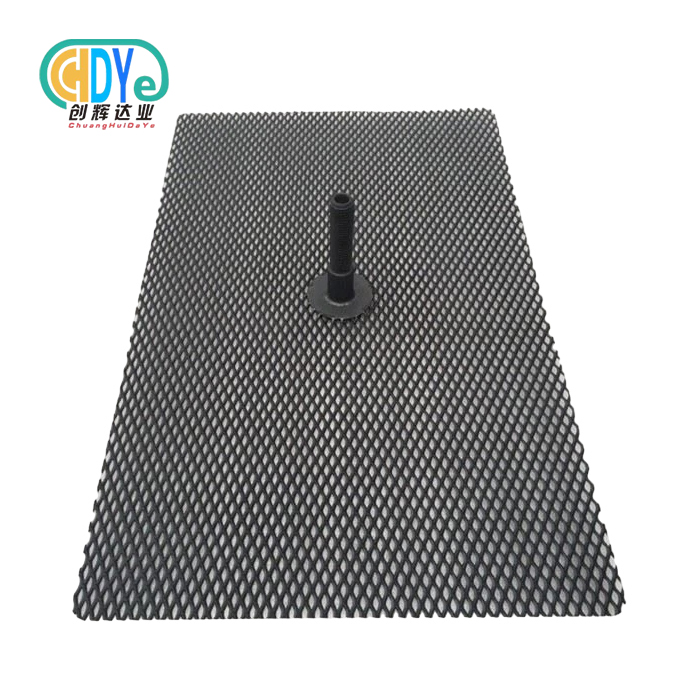

Applications and Industries

Your tubes serve critical roles across multiple sectors:

- Aerospace - Jet engines, rocket components, spacecraft parts

- Chemical Processing - Reactor vessels, heat exchangers, pipelines

- Medical - Surgical implants, prosthetics, diagnostic equipment

- Nuclear - Reactor components, fuel assemblies, cooling systems

- Electronics - Vacuum tubes, capacitors, superconducting magnets

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

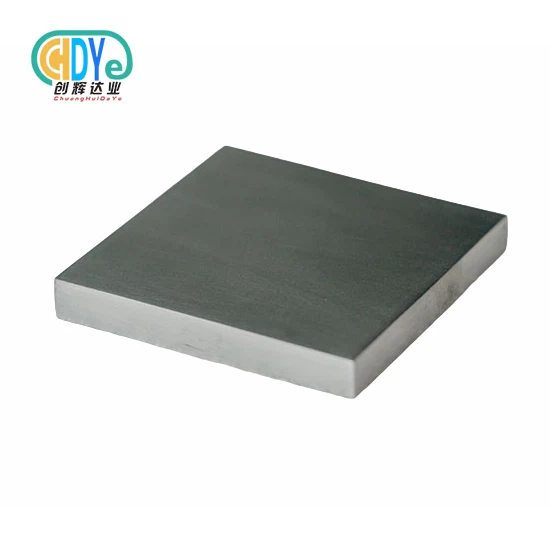

Product Dimensions and Tolerances

We maintain tight tolerances for precision applications:

- Outer diameter tolerance: ±0.05mm

- Wall thickness tolerance: ±0.02mm

- Length tolerance: ±5.0mm

- Straightness: 0.5mm per meter maximum

Product Features in Detail

Each tube showcases exceptional craftsmanship. The smooth internal surface ensures optimal fluid flow. Our precise wall thickness provides consistent performance throughout the entire length. The excellent surface finish reduces contamination risks and simplifies cleaning procedures.

Quality Assurance and Testing

We conduct comprehensive testing on every batch. Dimensional inspections verify precise measurements. Chemical analysis confirms proper alloy composition. Mechanical testing validates strength properties. Non-destructive testing ensures internal integrity. Your niobium alloy tube meets or exceeds all specified requirements.

OEM & Customization Services

We understand your unique requirements demand tailored solutions. Our engineering team works closely with you to develop custom specifications. We can modify dimensions, alloy compositions, and surface treatments. Special packaging and marking options are available to meet your exact needs.

Packaging and Shipping

Your products receive careful protection during transport. We use shock-resistant packaging materials and moisture barriers. Detailed labeling ensures proper identification and handling. Our logistics team coordinates efficient delivery to your location worldwide.

|

|

|

|

|

|

|

|

|

Why Choose Us

Shaanxi Chuanghui Daye brings three decades of metallurgical expertise to every project. We maintain ISO-certified quality systems and serve customers in over 50 countries. Our competitive pricing, reliable delivery, and exceptional customer service set us apart from competitors.

|

|

|

|

|

|

FAQs

Q: What minimum order quantities do you require?

A: We accommodate both small prototype orders and large production runs.

Q: Can you provide material certificates?

A: Yes, we supply complete mill test certificates with every shipment.

Q: What lead times should I expect?

A: Standard products ship within 1-2 weeks, custom orders typically require 2-3 weeks.

Contact Us

Ready to discuss your specific requirements? Our technical specialists are here to help you select the perfect solution. Contact us today at info@chdymetal.com or reach out through our website. We look forward to partnering with you on your next project and delivering the exceptional quality you deserve.

Learn about our latest products and discounts through SMS or email